ZHN-S Series Industrial Nitrogen Generators for Laser Welding

*(60Nm³/h High-Capacity Models with Smart PLC Control)*

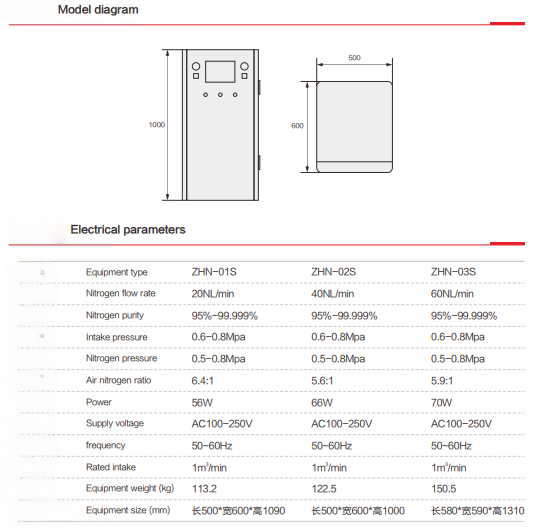

Technical Specifications Comparison

| Parameter | ZHN-01S (20Nm³/h) | ZHN-02S (40Nm³/h) | ZHN-03S (60Nm³/h) |

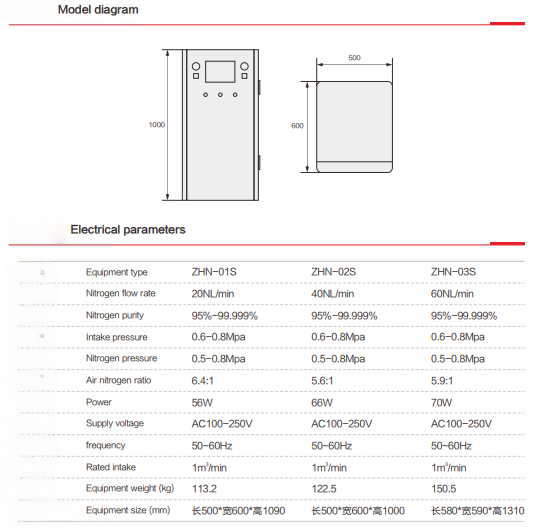

| Dimensions (L×W×H) | 500×600×1090mm | 500×600×1000mm | 580×590×1310mm |

| Weight | 113.2kg | 122.5kg | 150.5kg |

| Power Consumption | 56W | 66W | 70W |

| Air-Nitrogen Ratio | 6.4:1 | 5.6:1 | 5.9:1 |

| Noise Level | ≤62dB(A) | ≤64dB(A) | ≤68dB(A) |

Common Features:

✔ 95%-99.999% adjustable purity

✔ 0.5-0.8MPa output pressure (±1%)

✔ 100-250V AC, 50/60Hz global voltage

⚙️ Core System Components

Smart Control Panel

7" multilingual touchscreen (EN/DE/JP/CN/ES)

50+ preset welding programs

Real-time O₂ monitoring (0-25% range)

Advanced Air Treatment

PSA Generation Module

Performance Data by Material

| Application | Optimal Settings | Weld Quality |

| 2mm Stainless | 18L/min @ 99.9% | Ra 0.3μm, zero discoloration |

| 4mm Aluminum | 35L/min @ 99.99% | Porosity <0.02% |

| 6mm Titanium | 25L/min @ 99.999% | ASTM F136 compliant |

️ Installation & Maintenance

Space Requirements:

Service Intervals: