Application of carbon dioxide laser marking machine on wood products

The laser of the carbon dioxide laser marking machine is a gas laser. The wavelength it produces is 10.6um, which belongs to the mid-infrared frequency band. The CO2 laser has relatively large power and relatively high electro-optical conversion efficiency, and is currently the most powerful laser. .

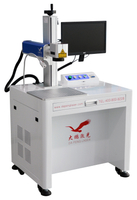

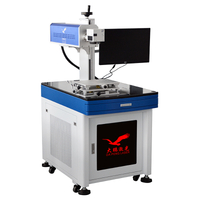

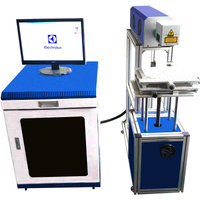

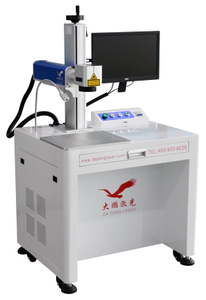

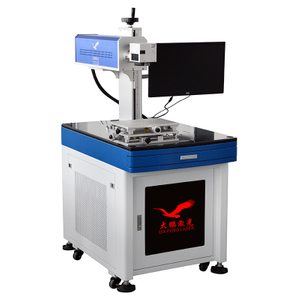

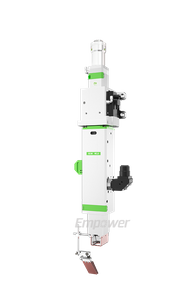

The carbon dioxide laser marking machine is flexible and compact in structure. The bracket is easy to install on the assembly line, and it is easy to adjust up and down. Even if the working conditions are complicated, the assembly line can be carried out freely. Compared with the traditional marking technology, the advantages of the co2 laser marking machine are that the laser marking is clear and durable, fast, high yield, and environmentally friendly; graphics, text and serial numbers can be edited through software, which is easy to change, and the laser 30,000 Hourly maintenance-free, no consumables, low cost of use, power saving and energy saving, marking environmental protection, in line with ROHS standards.

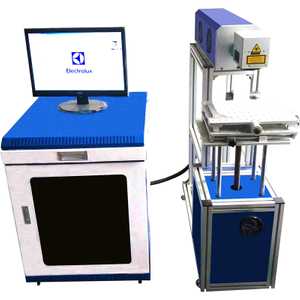

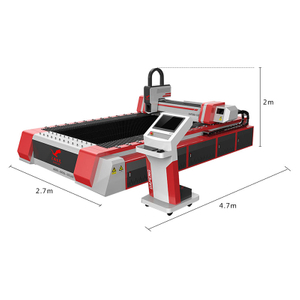

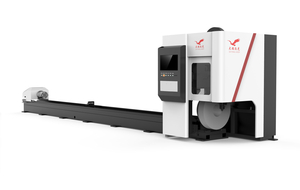

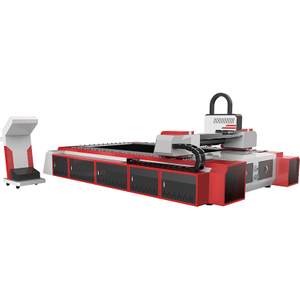

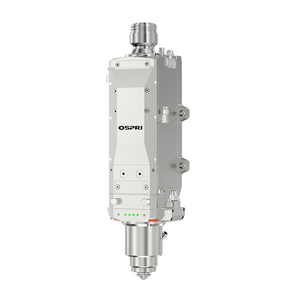

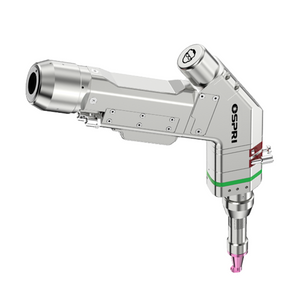

Carbon dioxide laser marking machine

CO2 laser marking has become an integral part of many industrial marking processes and has penetrated into every aspect of today's industrial manufacturing. Especially with the rapid development of UV laser marking machines and 3D laser marking machines, laser marking has become more and more prominent in the field of fine processing.

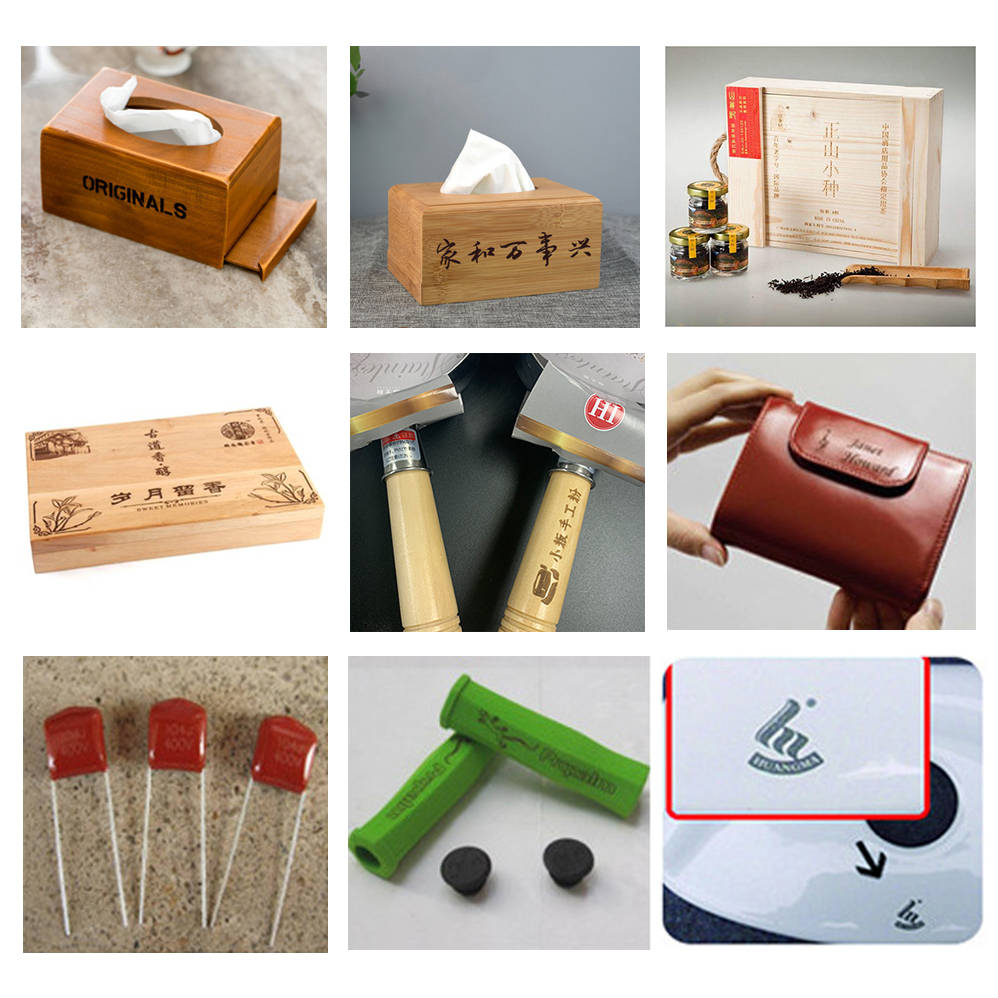

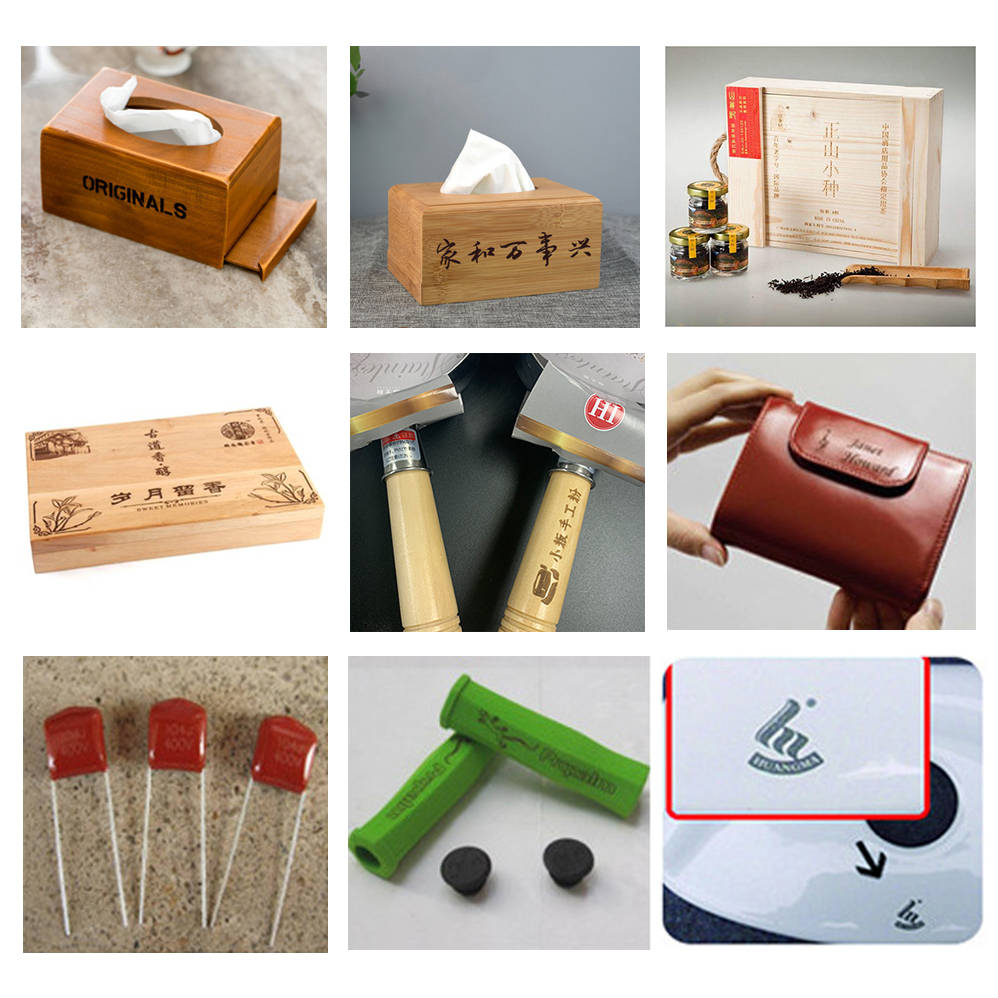

Application of CO2 laser marking machine: CO2 marking machine can be used to mark a variety of non-metallic materials and some metal products. Such as leather, architectural ceramics, acrylic, wood, paper, bamboo products, ABS, PVC, EP, epoxy resin, glass, rubber, etc. Widely used in beverage packaging, pharmaceutical packaging, food packaging, plastics, textiles, leather, wood, handicrafts, electronic components, communications, watches, glasses, printing and other industries.

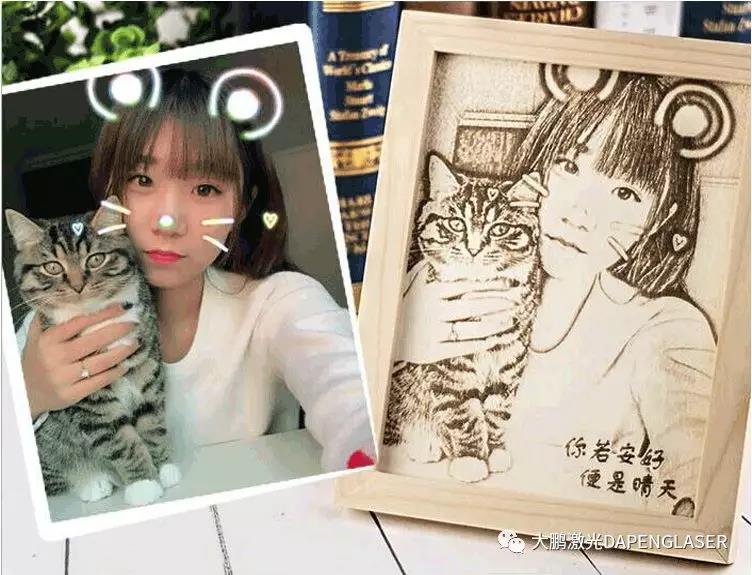

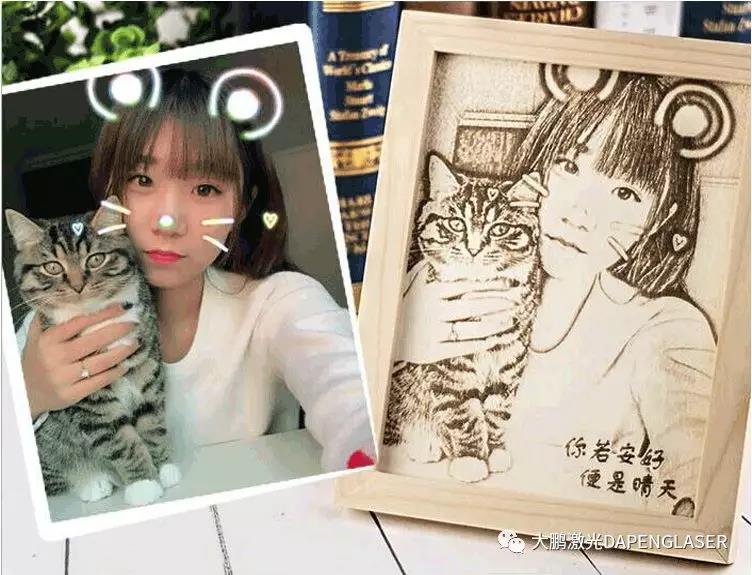

More and more exquisite and unique bamboo and wood products are widely loved by consumers, and it is a very fulfilling thing to carve your own mark on bamboo and wood products. However, traditional wood products are hand-carved, which is time-consuming and labor-intensive, and has strict requirements on the craftsmanship and artistic sense of the processor, while the bamboo and wood products laser engraving machine uses laser technology to engrave text on objects. The characters engraved by this technique have no nicks, the surface of the object is still smooth, the writing will not wear out, and the engraving speed is fast.

Compared with the traditional manual engraving method, the advantages of laser engraving are:

1. It is widely used, and various substances (bamboo, glass, ceramics, plastic, leather, etc.) can be marked for a long time.

2. It has no force on the surface of the workpiece, will not deform the bamboo and wood products, and will not corrode the surface of the material.

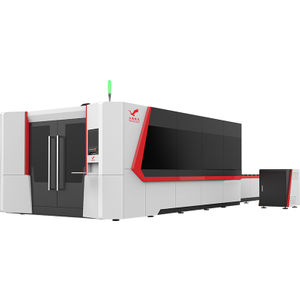

As the complexity of the cutting and engraving process increases, traditional manual processing and mechanical processing are restricted by equipment and technology, and the precision of the processed object is low. Therefore, it will affect the quality of the product and even affect the economic benefits.

Laser engraving processing is based on the use of numerical control technology, and laser is the processing medium. The physical denaturation of the material being melted and vaporized under laser irradiation to achieve the purpose of processing.

Laser processing features: There is no contact with the surface of the material, it is not affected by mechanical movement, the surface will not be deformed, and generally does not need to be fixed. Not affected by the elasticity and flexibility of the material, it is convenient for soft materials. High machining accuracy, fast speed and wide application fields.