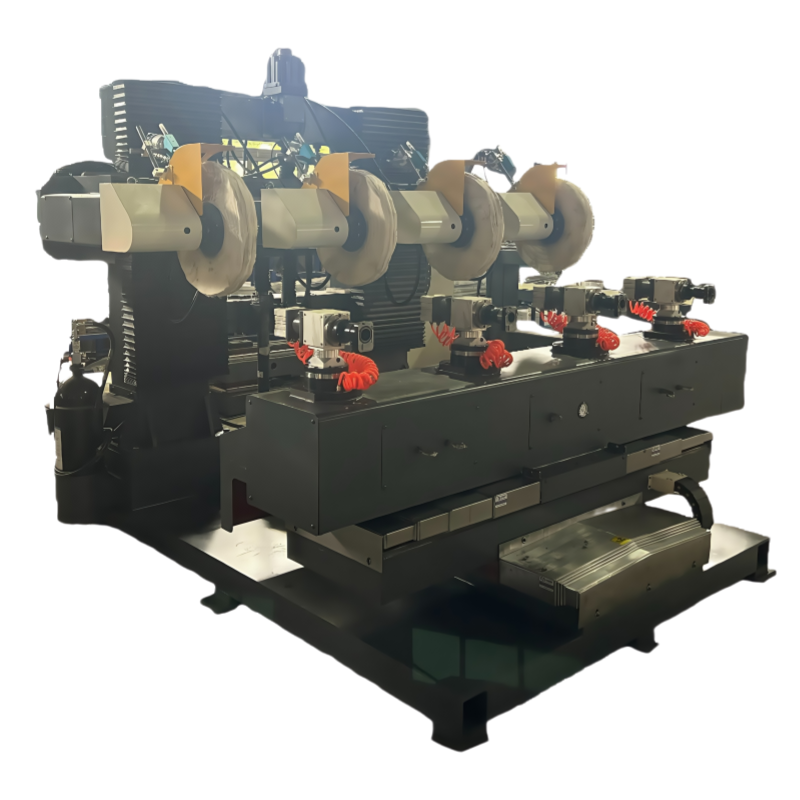

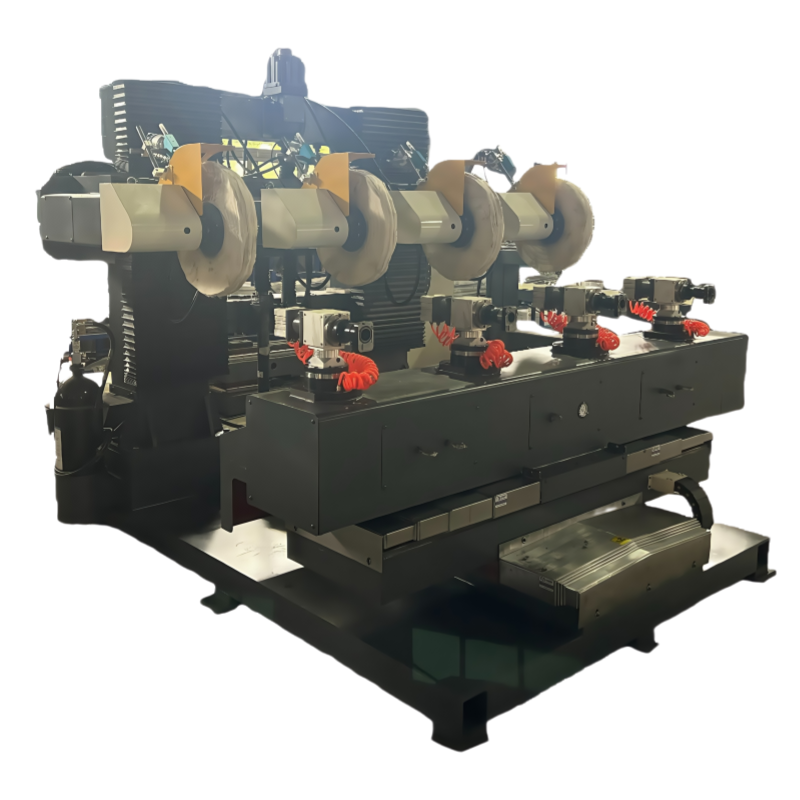

CNC Polishing Machine for Polishing and Brightening Door Locks and Sanitary Faucet Bodies

The CNC Polishing Machine for Polishing and Brightening is a highly advanced and versatile machine designed to automate the polishing, brightening, and finishing of door lock components, sanitary faucet bodies, and other intricate parts. With five programmable interpolating CNC axes, this machine provides precise control over the entire polishing process, making it ideal for high-precision industries such as door lock manufacturing, faucet production, and bathroom fittings.

This state-of-the-art machine is engineered for high efficiency and optimal finish quality, enabling manufacturers to produce components with complex shapes and geometries while ensuring consistency and superior surface finishes. Whether it’s polishing the surface of door locks, faucet handles, shower heads, or other bathroom accessories, this machine is capable of handling multiple tasks like deburring, grinding, polishing, and satin finishing with minimal human intervention.

Key Features and Benefits

Five Programmable Interpolating CNC Axes

Equipped with five programmable interpolating CNC axes, this machine offers precise control over the entire polishing process. The machine’s ability to adjust its axes allows it to handle a wide variety of parts with complex geometries. Whether dealing with intricate door lock components, sanitary faucet bodies, or faucet handles, the machine ensures uniform polishing across all surfaces, regardless of shape or size. The flexibility of the five axes makes it suitable for both simple and complex polishing tasks, providing manufacturers with the ability to meet demanding production needs.

Automated Polishing for Complex Parts

This machine is specially designed for the automated polishing of parts with complex shapes, such as door locks, faucet handles, and bathroom fittings. Traditional polishing methods may struggle to achieve the same level of precision and consistency, especially when dealing with multiple surface angles, tight corners, or irregular shapes. With this CNC polishing machine, these parts can be processed with high accuracy, ensuring a flawless finish every time.

The machine also excels in brightening parts to enhance their appearance, giving them a high-shine, mirror-like finish. This is especially important for sanitary faucet bodies and door lock elements, which require an aesthetic appeal that matches both their functional and decorative purpose.

Simultaneous Processing of Four Parts

One of the standout features of this CNC polishing machine is its ability to simultaneously process four parts in each cycle. This is particularly beneficial in high-volume production environments, where reducing cycle times and increasing throughput are essential for maximizing efficiency. The ability to polish four parts at once significantly improves productivity, while maintaining the same level of precision and finish quality.

Versatile Applications

This machine offers multiple applications that make it a versatile tool for a variety of industries. These applications include:

Deburring: Effectively removing sharp edges and burrs that can arise from manufacturing processes such as casting or machining.

Grinding: Smoothing rough surfaces to prepare the part for further finishing or to achieve a specific texture.

Polishing: Achieving a high-gloss, reflective surface that is particularly important for aesthetic products like bathroom faucets, shower handsets, and door locks.

Satin Finishing: Producing a brushed, matte finish that is often required for more industrial-style faucets and fittings.

This versatility ensures that the CNC machine can be used for a wide range of parts and finishes, offering manufacturers flexibility in their production processes.

Teach-In Programming for Easy Setup

The teach-in programming feature makes the setup process intuitive and easy to manage. Operators can teach the machine how to perform specific polishing actions, reducing the need for advanced programming skills. The machine stores these taught programs for future use, ensuring a repeatable, efficient process with minimal setup time. This feature makes it particularly valuable for manufacturers who need to quickly adapt to changes in production requirements.

High-Quality Surface Finish

This CNC polishing machine guarantees homogeneous polishing without deformation. Thanks to its precise control system, the machine ensures that every part receives the same level of attention and polish, resulting in a consistent surface finish across all components. Whether you need a mirror-like finish, satin texture, or matte polishing, the machine can deliver the required quality with accuracy.

The automated process ensures that parts are polished evenly, eliminating the imperfections that are often found with manual polishing methods. This guarantees a uniform and high-quality surface finish that meets the most stringent aesthetic and functional requirements.

Automatic Spraying Gun Adjustment

The machine is equipped with automatic spraying gun adjustment, which adjusts the position of the spraying guns in accordance with the diameter of the polishing mops. This ensures that the polishing compound is applied evenly across the part’s surface, regardless of its size. The automatic adjustment feature further enhances the machine’s ease of use and reduces setup time, allowing operators to switch between different parts quickly.

Low Operating Costs and Energy Efficiency

Designed with low operating costs in mind, this CNC polishing machine is highly energy efficient, helping manufacturers reduce their production costs. The machine uses minimal polishing compounds and mops, cutting down on consumables and making it a more sustainable choice for high-volume production. Additionally, the high level of automation reduces the need for manual labor, further lowering operational expenses.

Flexible Production and Quick Setup

One of the key advantages of this machine is its flexibility. It is capable of quickly switching between different parts and models, allowing for quick setup when production needs change. The system allows for the easy replacement of polishing mops and grippers, enabling manufacturers to adjust the machine for different parts with minimal downtime.

This flexible production capability ensures that the machine can adapt to a wide variety of production runs, making it an excellent choice for manufacturers who need to process different types of parts without sacrificing efficiency or quality.

Applications

Faucets and Bathroom FittingsThe CNC polishing machine is particularly well-suited for polishing faucets and bathroom fittings, which often require a high-gloss finish. The machine’s ability to process parts like faucet handles, spouts, valves, and shower heads makes it a versatile solution for the bathroom fixture manufacturing industry. The machine can handle various finishes, including mirror-like polishing or satin finishes, depending on the product’s design requirements.

Door Lock ComponentsIn the door lock manufacturing industry, the machine can be used to polish and brighten lock bodies, key cylinders, and other components. Since door locks require both functional durability and aesthetic appeal, this machine ensures that each part receives the precise treatment it needs for both visual appeal and proper functionality.

Sanitary Fittings and AccessoriesThe machine is also ideal for polishing and finishing other sanitary fittings, such as bathroom accessories, toilet flush handles, and shower fittings. By ensuring high-quality finishes and quick production cycles, this machine is an excellent tool for manufacturers of sanitary accessories who need to meet both design and performance standards.

Conclusion

The CNC Polishing Machine for Polishing and Brightening Door Locks and Sanitary Faucet Bodies is a high-performance solution that combines precision, high production capacity, and flexibility for the automated polishing and finishing of complex parts. Whether it is for faucet handles, shower heads, door locks, or other bathroom and sanitary components, this machine guarantees optimal surface finishes, reduced operational costs, and high throughput.

With features like five programmable CNC axes, simultaneous processing of four parts, and intuitive teach-in programming, this machine is designed to meet the demanding needs of modern manufacturing. It provides the ability to process multiple parts simultaneously, handle various types of finishes, and adapt to different part geometries—all while ensuring high-quality and homogeneous results. For manufacturers looking to scale production, improve efficiency, and maintain superior quality, this CNC polishing machine is an indispensable asset.