Hand-held laser welding machine with chuangxin MAX fiber laser and Super Hand-held welding head 20S

Model features:

1.High energy density, low heat input, small amount of thermal deformation, and narrow melting depth in the heat and heat affected zone of the melting zone.

2.The cooling rate is high, so that the weld structure can be fine and the joint performance is good.

3.Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly improving work efficiency.

4.The weld is fine, the penetration is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

5.No consumables, small size, flexible processing, low operating and maintenance costs

6.The laser is transmitted through the optical fiber and can work with the assembly line or the robot.

7.The touch switch is equipped with a safety clip, and the laser beam can only be emitted when the welding nozzle touches the metal.

8.Red light positioning is used to verify the position during welding.

9.The laser welding machine adopts 1000-2000 watt fiber laser source, which has high photoelectric conversion efficiency and long life of 100,000 hours. The energy provided by electric energy is 25%-30% converted into laser energy, and the photoelectric conversion rate is many times that of YAG laser.

Detailed Images

Model | DPH-1000 | DPH-1500 | DPH-2000 | DPH-3000 |

Laser Out Power | Fiber source | Fiber source | Fiber source | Fiber source |

Laser Source Type | 1000W | 1500W | 2000W | 3000W |

Laser Wavelength | 1070nm | 1070nm | 1070nm | 1070nm |

Laser Source | Raycus/Max/IPG | Raycus/Max/IPG | Raycus/Max/IPG | Raycus/Max/IPG |

Focal Spot Diameter | 0.5-2mm | 0.5-3mm | 0.5-4mm | 0.5-5mm |

Laser Frequency | 1-50Hz | 1-50Hz | 1-50Hz | 1-50Hz |

Repeatability | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

Machine Operating Temperature | 0~40℃ | 0~40℃ | 0~40℃ | 0~40℃ |

Electricity Demand | 220V/380v | 220V/380v | 220V/380v | 220V/380v |

Cooling Method | Water chiller | Water chiller | Water chiller | Water chiller |

Continuous Operating Time | 24 hours | 24 hours | 24 hours | 24 hours |

Weight | 150kg | 150kg | 150kg | 150kg |

Dimensions | 120*60*104cm | 120*60*104cm | 120*60*104cm | 120*60*104cm |

Laser Control System | Dapeng Touch screen | Dapeng Touch screen | Dapeng Touch screen | Dapeng Touch screen |

DPH-1000/1500/2000-SC handheld laser welding machine

Hand-held laser welding machine with raycus continuous fiber laser and suplaser hand-held welding head

The light of the laser is transmitted by the optical fiber line to the hand-held laser welding gun and emits the laser. The laser becomes heat and is transferred to the surface of the carrying object for melting or the welding wire is melted. The welding bead is formed by the auxiliary inert gas protection, so that the two objects are firmly bonded together. .

(The chiller water flows to the laser and the hand-held welding head to cool down and maintain the temperature, thereby protecting important components.)

Super Hand-held welding head 20s

1. Basic features: self-developed control system, multiple safety alarms, smaller size, flexible operation and easy to use.

2. More stable: All parameters are visible, real-time monitoring of the status of the whole machine, to avoid problems in advance, more convenient to troubleshoot and solve problems, to ensure the stable operation of the welding head.

3. Process: All parameters are visible, the welding quality is more perfect, the deformation is small, and the penetration is high.

4. Stable parameters and high repeatability: the determined nozzle air pressure and lens state, as long as the laser power is stable, the process parameters must be repeatable. Greatly improve efficiency, while also reducing operator requirements.

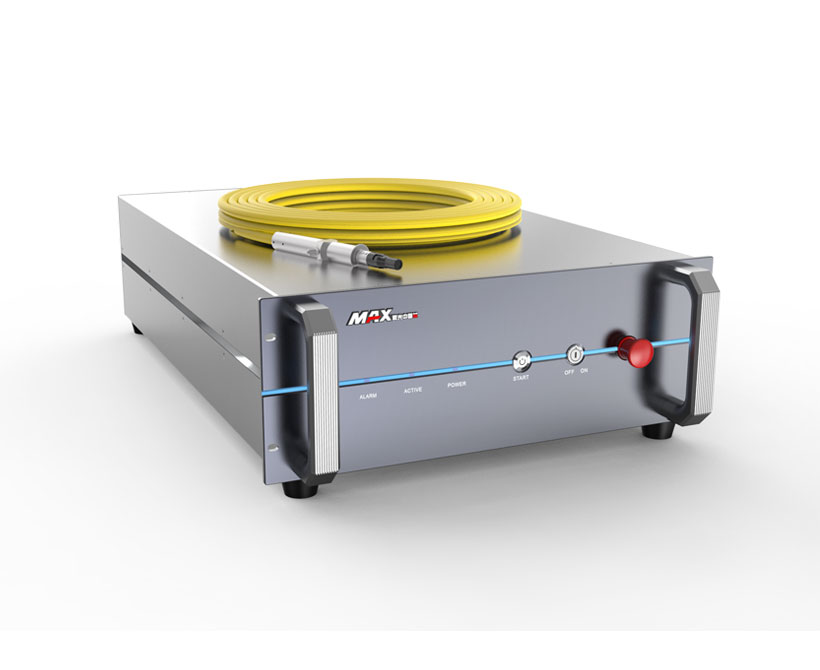

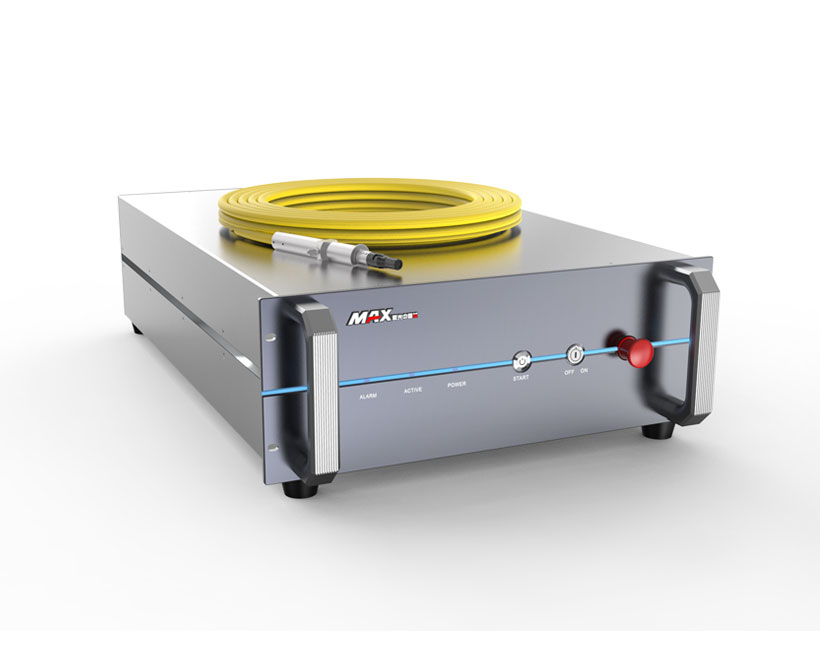

MFSC 700W-1500W single-mode continuous fiber laser adopts modular design, highly integrated system, maintenance-free, and high reliability. The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cutting, precision welding and other applications. Using optical fiber with QBH head output, it can be used with laser processing heads, galvanometers, etc. to integrate with robots, machine tools, etc., and is widely used in 3C, hardware, medical, automotive, aviation and other fields.

Product Description

MFSC 700W-1500W single-mode continuous fiber laser adopts modular design, highly integrated system, maintenance-free, and high reliability. The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cutting, precision welding and other applications. Using optical fiber with QBH head output, it can be used with laser processing heads, galvanometers, etc. to integrate with robots, machine tools, etc., and is widely used in 3C, hardware, medical, automotive, aviation and other fields.

Product leaflet

Product Manual

Modular design, stable performance

The internal structure adopts the photoelectric module separation design, and the operating performance is more stable

Easy maintenance, reducing downtime

Optical modules, electrical modules, control units, and drive units can be directly replaced, upgraded, and maintained at the client

Can be customized to meet a variety of needs

Users can choose fibers with different core diameters according to different processing needs to meet differentiated processing needs

Even spot energy distribution, stable processing

Reduce welding spatter, thick plate cutting ability is more stable

Multi-scene, wide application

It can be used with laser processing heads, galvanometers, etc. for system integration with robots, machine tools, etc., for laser fine cutting, precision welding, and application in 3C, hardware, medical, automotive, aviation and other fields

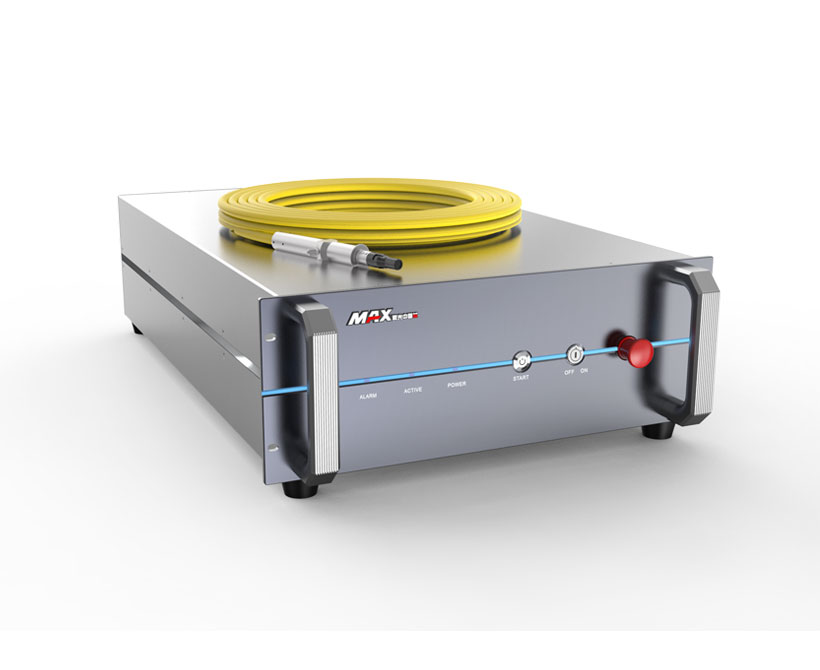

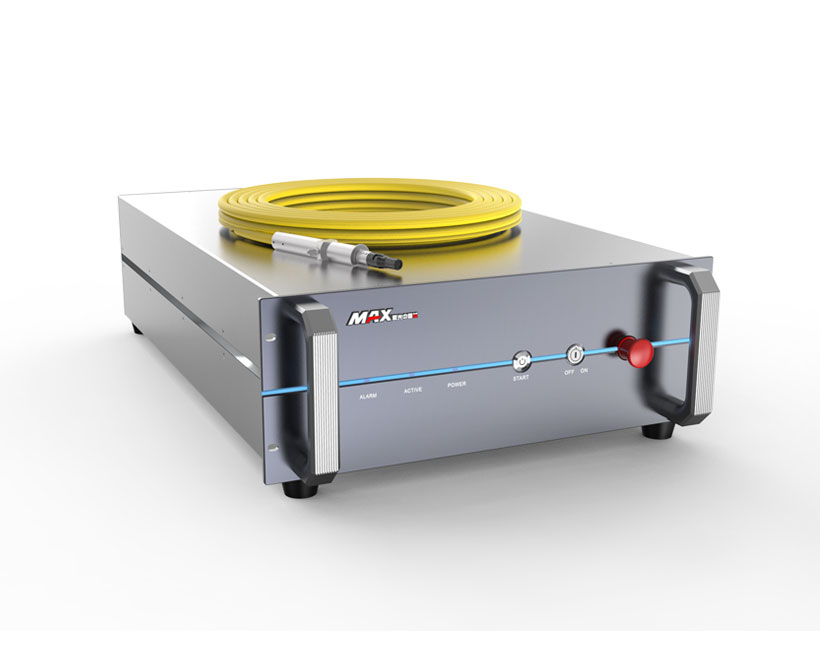

MFSC-2000W Single Module Continuous Fiber Laser

It can be quickly and conveniently integrated into machine tool equipment and automated production lines of large processing manufacturers.

Product Description

Chuangxin Laser's new generation single-module 2000W laser, this product integrates high power, lightweight size, humanized control, high-quality beam quality, and high light conversion efficiency. It can meet the requirements of precision processing. 3C product welding and high-reflection material cutting capabilities are significantly improved. It is suitable for remote processing. The laser cutting frequency is high and the cutting surface is smooth. It can be quickly and conveniently integrated into machine tools and large-scale processing manufacturers' automated production lines.

High power output, compact size

Combines high power, compact size, user-friendly control, high-quality beam quality, and high light conversion efficiency in one

Modular design, easier to maintain

Adopt photoelectric separation design, quickly replace the optical path or circuit module on site

Independent control to reduce downtime

Adopt single pump control technology, can realize independent control, quickly shut down a single abnormal pump source and still run

Intelligent monitoring, easy operation

Embedded with a new generation of intelligent software independently developed by Chuangxin Laser, real-time dynamic monitoring of various operating indicators of the laser

High integration and wide application

It can be quickly and easily integrated into machine tool equipment and automated production lines of large processing manufacturers