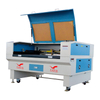

100W single head CO2 laser cutting machine laser carving cutting machine 6090 acrylic wood medium density fiberboard leather carving machine

application area

CO2 laser cutting machine is suitable for non-metallic materials such as leather, fabric, epoxy resin, wood products, paper, acrylic, wool, plastic, rubber, bamboo products, etc.

Working width (mm): 600 × 900/1000 × 800/1200 × 600/1300 × 900/1600 × one thousand

Boundary dimension (mm): 1530 × one thousand and seventy × 1070/1825 × one thousand five hundred and eighty × 1200/1910 × one thousand three hundred and eighty × 1100/1910 × one thousand seven hundred and ten × 1370/2240 × one thousand seven hundred and eighty × one thousand two hundred and ninety

Total weight (kg): 260/430/430/525/605

WORKING AREA- 600*900

TUBE POWER - T-2

RF- 100 WATT - HY

MOTOR AND DRIVE- UVW THREE PHASE (LEADSHINE/ YAKO)

BLOWER - 750 W

COMPRESSOR- 380W HEALIA (TWO HEAD MACHINE NEED 2 PCS )

MIRROR- 30*3 SILVER COATED

LENS - 50.8 FL (BEST QUALITY USA COATED)

AIR PIPE LINE - 8 MM IN EACH MACHINE

WATER SENSOR- YES

PULLY - BRASS MATERIAL

BELT- 18 MM

CONTROLLER - RDC

BLOWER PIPE - GOOD QUALITY FABRIC MATERIAL

BED / WORKINT TABLE- HONEY COMB (SEPRATE FRAME )+KNIFE BLADE (EACH GAP 10 MM) SEPRATE FRAME

SENSOR- OMRON JAPAN

POWER SUPPLY - OMRON / MEANWELL

CHILLER- S&A (AS PER HEAD) 5200 SINGLE / DUAL HEAD

CUPPLER - 4 PCS IN EACH MACHINE

1. What is the principle of a carbon dioxide laser cutting machine

The principle of a carbon dioxide laser cutting machine is to generate laser light by utilizing the transition between the vibrational and rotational energy levels of carbon dioxide molecules.

The discharge tube of a carbon oxide laser is filled with mixed gases such as carbon oxide, and its specific gravity and total pressure can vary within a certain range.

Any molecule has three different forms of motion:

One is the motion of electrons in molecules, which determines the energy state of electrons,

Another type is the vibration of atoms in molecules, which means that atoms continuously vibrate periodically around their equilibrium position, and this motion determines the vibrational energy of the molecule,

The third is the rotation of molecules, which determines their rotational energy states.

The carbon dioxide laser cutting machine utilizes the conversion between the vibrational and rotational energy levels of carbon dioxide molecules to generate lasers.

The CO2 laser cutting process uses invisible beams of light to replace traditional mechanical knives. It has the characteristics of high accuracy, fast cutting speed, unrestricted cutting patterns, automatic typesetting, material saving, smooth cuts, and low processing costs, gradually improving or replacing traditional metal cutting equipment.

The mechanical part of the laser cutting head has no contact with the workpiece, and it will not scratch the surface of the workpiece during operation; Laser cutting speed is fast, the incision is smooth and flat, and generally does not require subsequent processing;

Small cutting heat affected zone, small plate deformation, and narrow gaps (0, 1mm~0, 3mm);

The incision is free of mechanical stress and shear burrs;

High machining accuracy, good repeatability, and no damage to the material surface; CNC programming, capable of processing any scheme, capable of cutting large format whole boards without the need for mold opening, economical and time-saving.

2. What are the types of carbon dioxide laser cutting machines?

Multi head carbon dioxide laser cutting machine: A carbon dioxide laser cutting machine with two or more heads. If the cutting speed is relatively high, a multi head carbon dioxide laser cutting machine can be used. Can be used for multiple laser cutting machines, with low cost and fast production speed.

Automatic feeding carbon dioxide laser cutting machine: The difference of this carbon dioxide laser cutting machine is that its workbench adopts a mobile platform and an automatic feeding rack, which is more convenient and efficient for processing flexible materials. In working conditions, the same strip conveying platform as ordinary laser cutting machines is used to improve the flatness of the platform, making it suitable for large-scale production in large and medium-sized enterprises. Not meeting the production needs of small businesses and individual workers, it is possible to watch multiple televisions per person, saving labor and costs. Beam laser

CCD camera carbon dioxide laser cutting machine: The characteristic of this carbon dioxide laser cutting machine is that it is equipped with a camera visual positioning system, greatly improving positioning and cutting accuracy, and cutting edges are smooth. Fast cutting speed. Automatic camera positioning and cutting. You can capture the contour of the cutting object to automatically cut edges. The camera laser cutting machine can perfectly and quickly cut irregular trademarks.

Metal and non-metal mixed cutting machine: mainly used for cutting advertising words, hence also known as advertising word laser cutting machine. Able to cut metal, cost-effective, mixed metal and non-metal laser cutting, low investment cost, low operating cost, and low maintenance cost.

Laser cutting machine: It greatly meets the needs of large format processing and large processing enterprises, improving their work efficiency and economic benefits. Breaking the problems of slow speed and difficult typesetting in traditional manual and electric shearing machines, fully solving the problems of low efficiency and waste of materials. Fast cutting speed and simple operation. Simply input the graphics and dimensions to be cut into the computer, and the machine will cut the entire material into the finished product you need, without the need for tools and molds. Using laser to achieve non-contact processing, the operation is simple and fast.