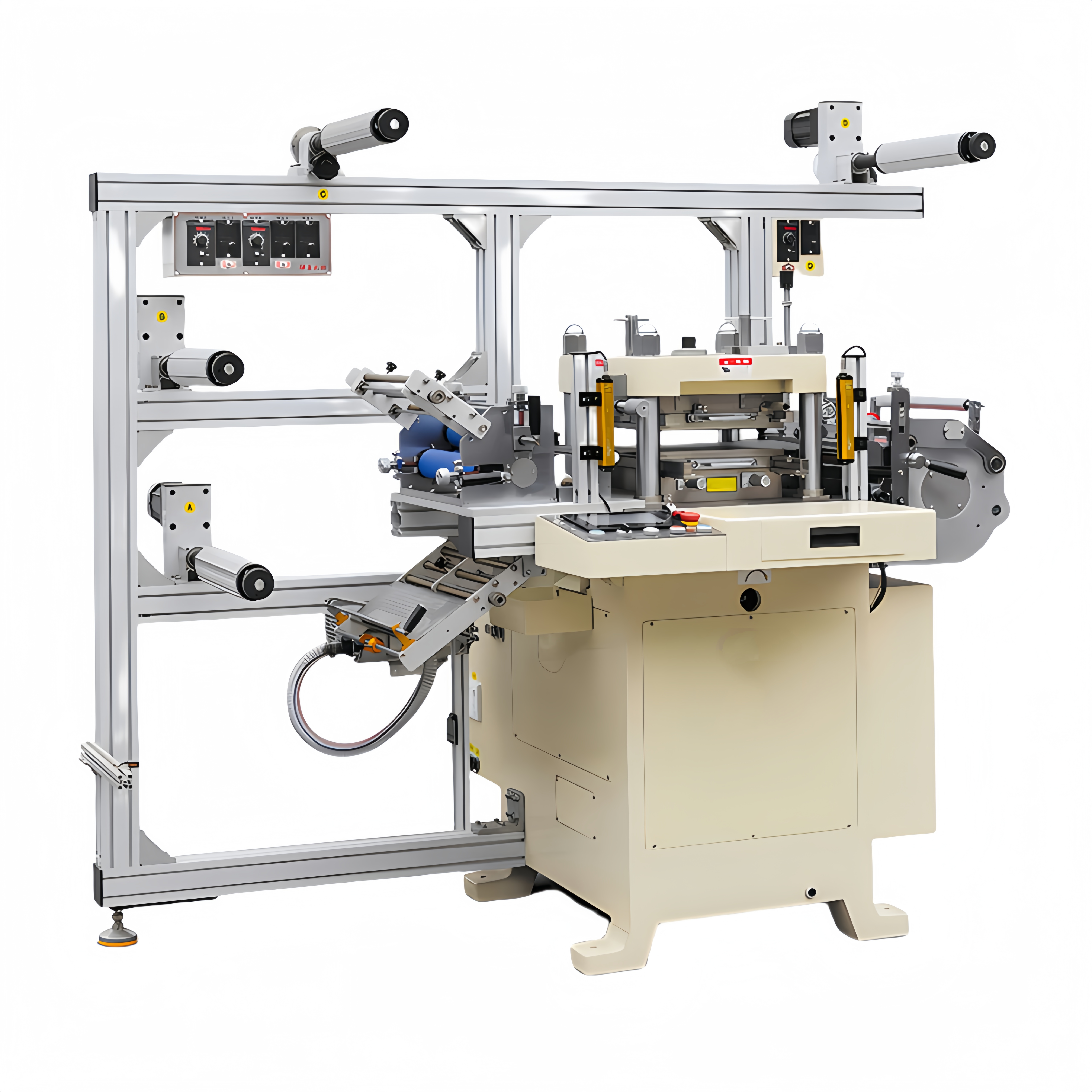

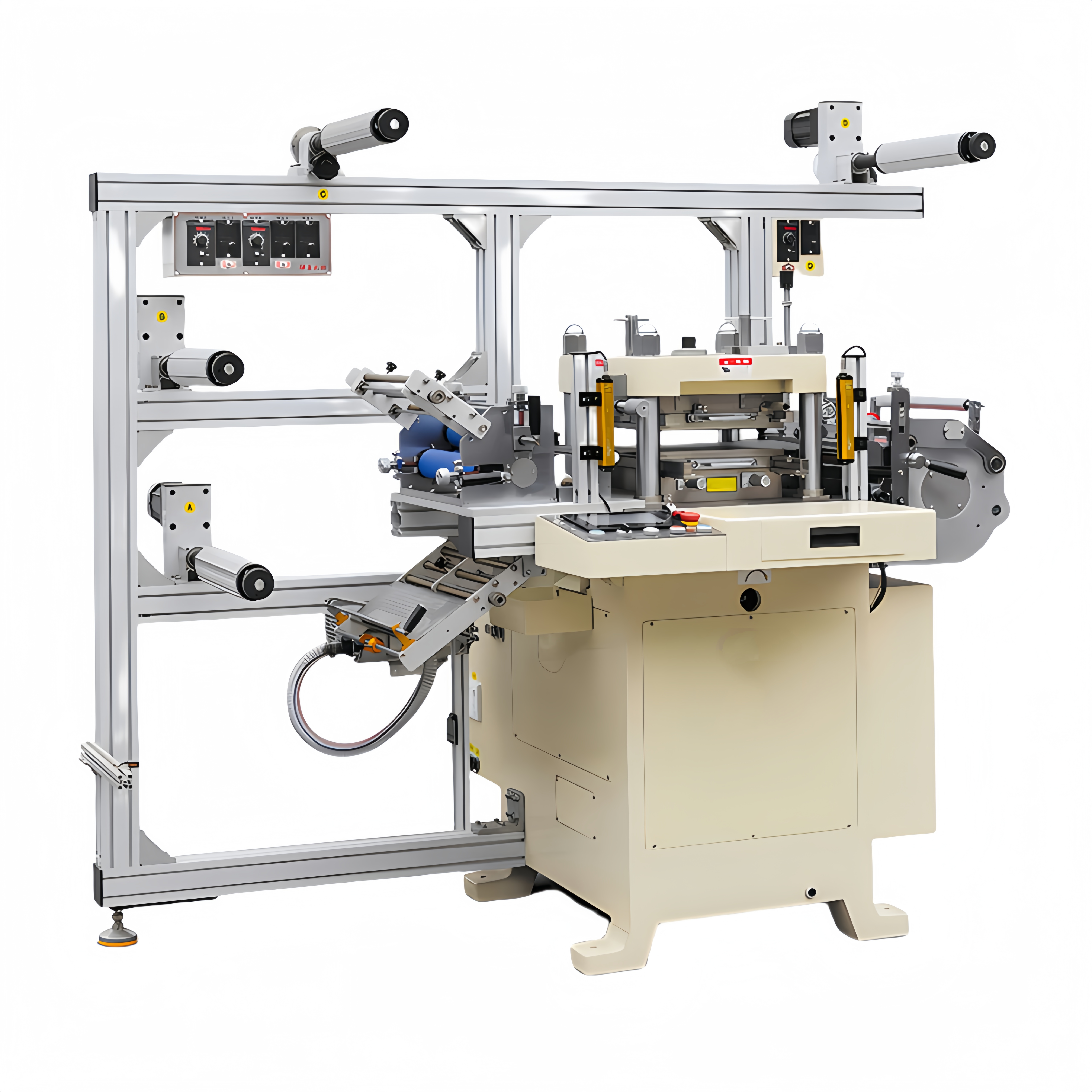

JNY-300/350/450 (In-mold Asynchronous Die Cutting Machine) series is specialized equipment designed for high-precision die cutting in various applications, typically used in the packaging, labeling, and printing industries.

1. (JNY-300 In-mold Asynchronous Die Cutting Machine)

Specifications:

Key Features:

In-mold Labeling Capability: Ideal for producing in-mold labels with high accuracy and precision.

Asynchronous Cutting: Allows for independent die cutting and feeding processes, improving production flexibility.

Quick Tool Change: Easy and fast die setup for multiple production jobs.

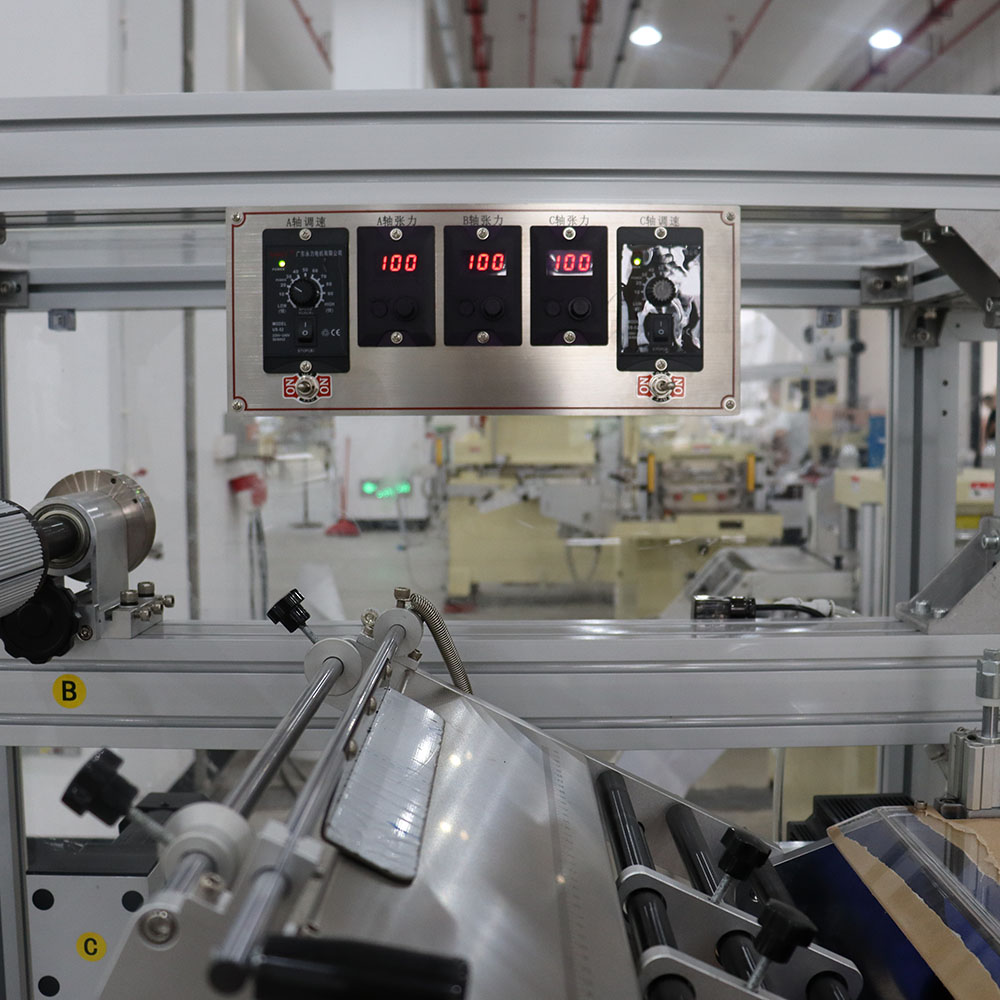

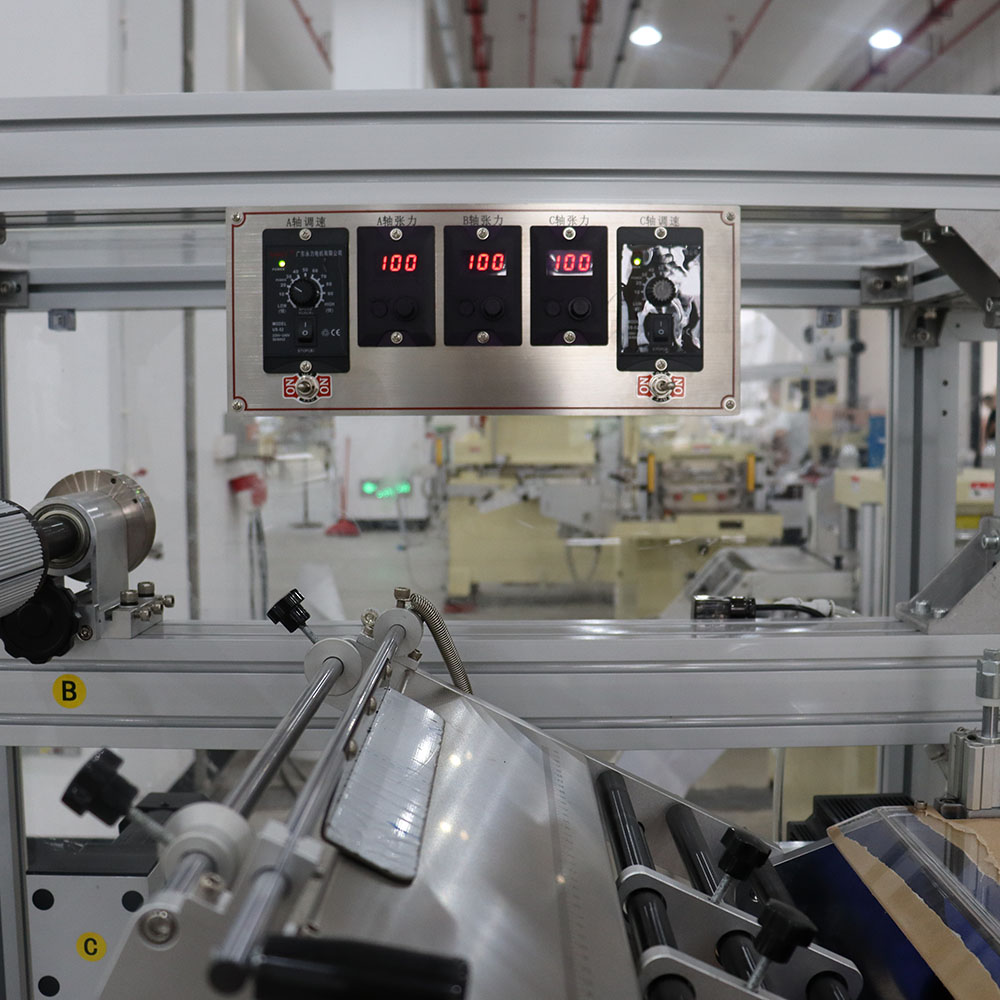

User-Friendly Control System: PLC control with a touchscreen interface for easy setup and operation.

Compact Design: Suitable for smaller workspaces and for small to medium production volumes.

2. (JNY-350 In-mold Asynchronous Die Cutting Machine)

Specifications:

Key Features:

Increased Capacity: Larger cutting width allows for processing wider materials, making it ideal for medium-scale label and packaging production.

Asynchronous Cutting Mechanism: Offers the ability to process jobs with different cutting patterns on the same machine, improving overall efficiency.

High Precision: Equipped with an optical sensor system to ensure cutting precision.

Automatic Web Alignment: Maintains material stability and alignment throughout the process.

Quick Job Setup: Shorter changeover times for different jobs, improving productivity.

3. (JNY-450 In-mold Asynchronous Die Cutting Machine)

Specifications:

Key Features:

Large-Scale Production: The larger cutting width and higher capacity make it ideal for industrial production lines.

Precision Die Cutting: Equipped with a servo motor system for high precision in repeated jobs, ensuring consistency across production batches.

Automatic Feeding System: Provides continuous material feed with automatic tension control for higher efficiency.

High Flexibility: Supports a wide range of materials and thicknesses, making it versatile for various packaging and label applications.

Safety and Automation: Comes with advanced safety sensors and automation features, reducing manual intervention and increasing operational safety.

Common Features Across JNY-300/350/450 Series:

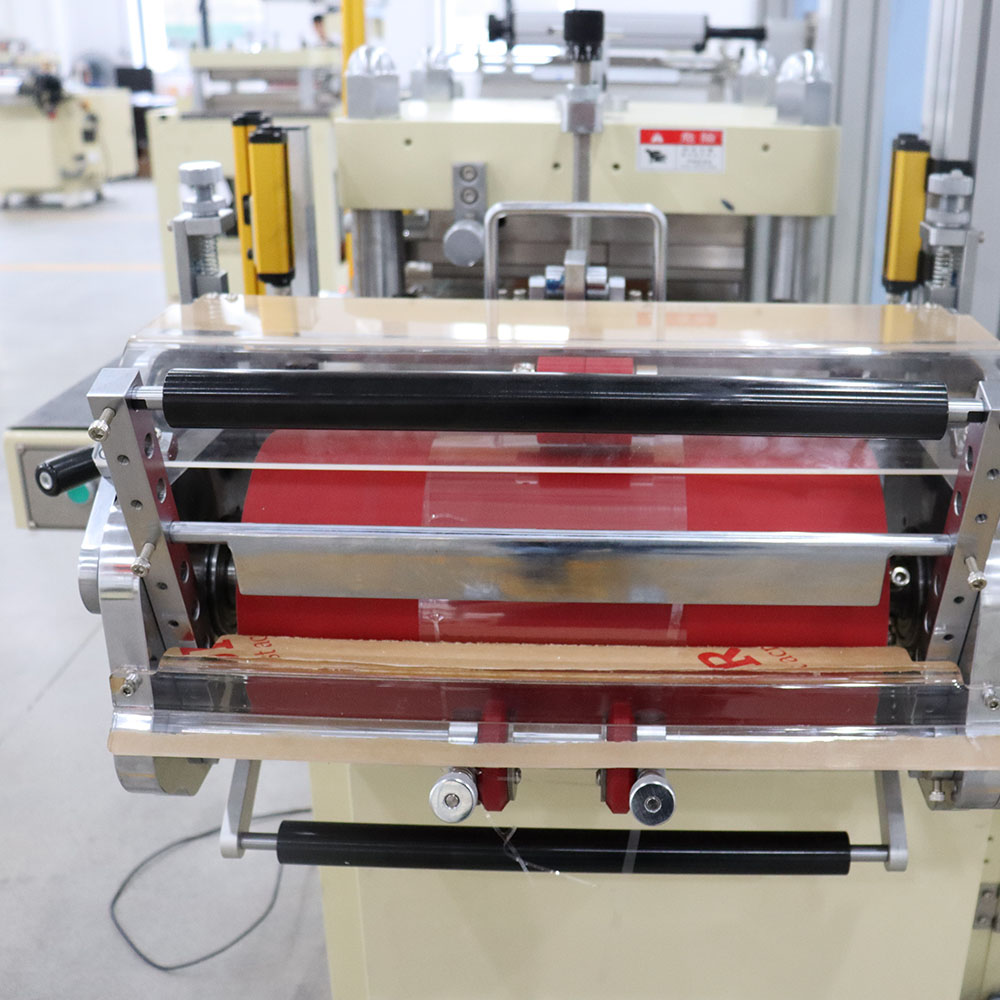

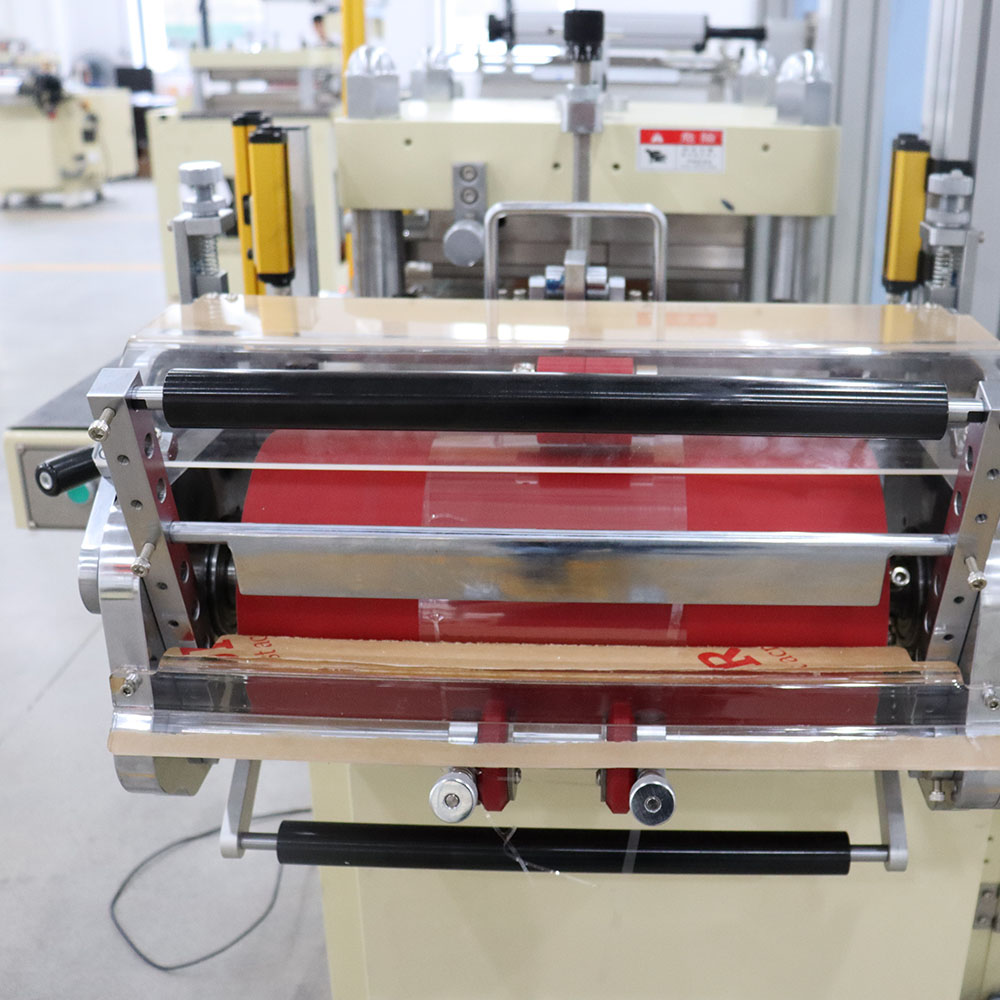

Asynchronous Cutting Mechanism: The die-cutting process operates independently of material feeding, allowing for more flexibility in cutting patterns and material handling.

High Efficiency: Capable of processing multiple layers of material simultaneously, improving throughput for both small and large production runs.

Modular Design: The machine allows for easy maintenance and quick part replacement, reducing downtime.

Automatic Registration System: Ensures accurate alignment of pre-printed materials, minimizing waste and enhancing product quality.

PLC Control with Touchscreen: Allows for programmable job settings and real-time monitoring of production processes.

Waste Stripping Unit (Optional): Helps to remove excess material or scrap automatically after die cutting, improving workflow efficiency.

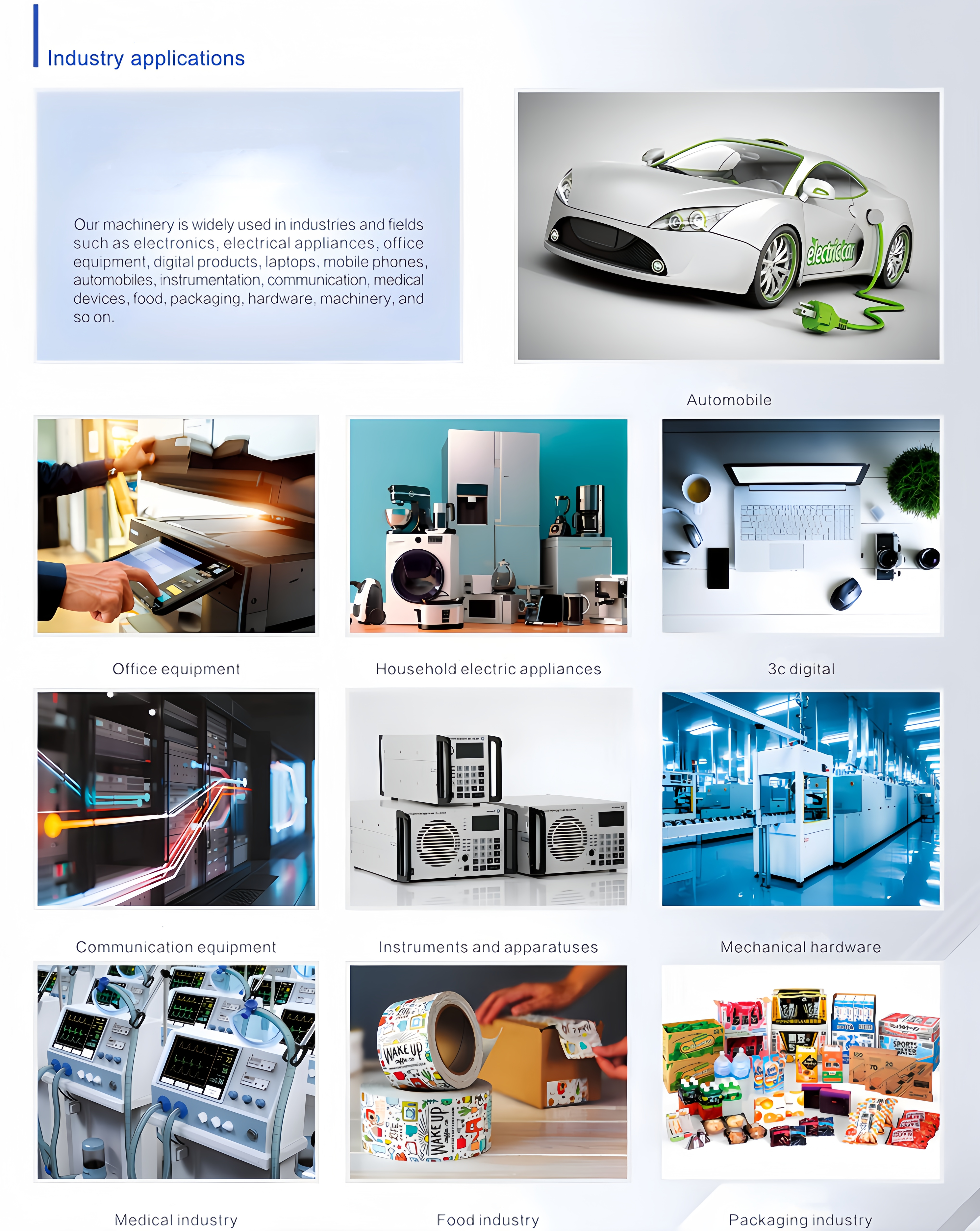

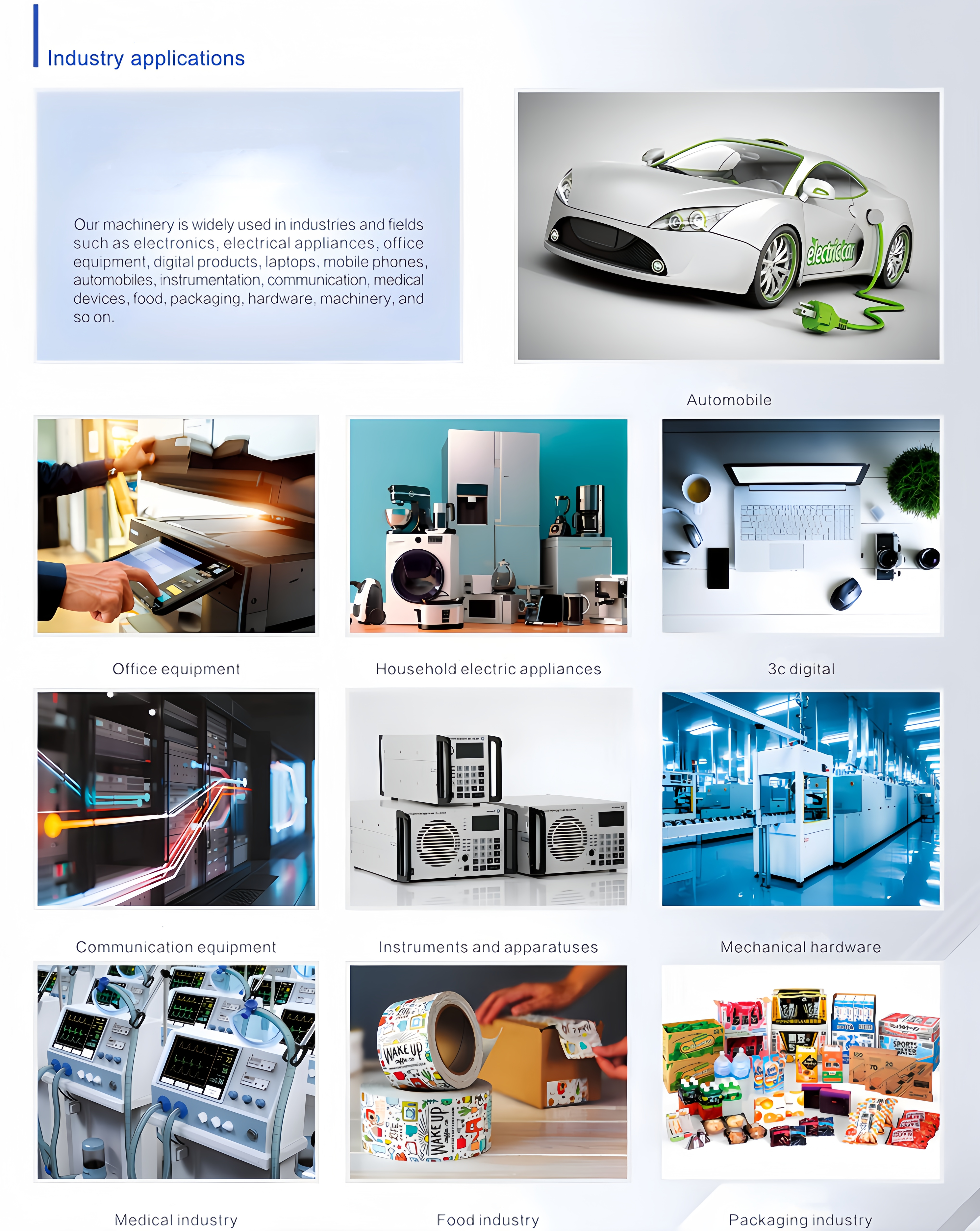

Applications:

Packaging Industry: Suitable for cutting packaging labels, boxes, and in-mold labels for plastic containers.

Labeling: Ideal for producing adhesive labels, stickers, and tags for various products.

Printing: Useful for high-precision cutting of printed materials, including promotional items and business cards.

Technical Specifications:

| Specifications | JNY-300 | JNY-350 | JNY-450 |

| Feed Width | 310 mm | 370 mm | 470 mm |

| Max. Die Cutting Area | 300 × 310 mm | 350 × 370 mm | 450 × 470 mm |

| Max. Operating Speed | 18000 punches/hour | 18000 punches/hour | 12000 punches/hour |

| Punching Stroke | 28 mm | 28 mm | 28 mm |

| Pressure Regulation | 30 mm | 30 mm | 30 mm |

| Voltage Regulation Accuracy | 0.005 mm | 0.005 mm | 0.005 mm |

| Drawing Accuracy | ±0.05 mm | ±0.05 mm | ±0.05 mm |

| Upper Form Size | 300 × 310 × 37 mm | 350 × 370 × 37 mm | 450 × 470 × 37 mm |

| Lower Template Size | 300 × 310 × 40.5 mm | 350 × 370 × 40.5 mm | 450 × 470 × 40.5 mm |

| Overall Dimensions | 2150mm × 1350mm × 1850mm | 2200mm × 1400mm × 1850mm | 2300mm × 1450mm × 1850mm |

| Machine Weight | 1200 kg | 1600 kg | 2200 kg |

| Air Source Specification | 0.5–0.7 MPa | 0.5–0.7 MPa | 0.5–0.7 MPa |

| Total Power | 8kW | 11 kW | 11.5 kW |

| Lubrication Mode | Intermittent fuel supply | Intermittent fuel supply | Intermittent fuel supply |

| Applicable Die Types | Plywood mold, wood mold | Plywood mold, wood mold | Plywood mold, wood mold |

Performance Characteristics:

Small hole positioning instant correction device.

Double servo drive for stable pressure, low noise, and precise drawing.

Electric digital display for quick and convenient voltage adjustment.

High punching force with stable die-cutting pressure.

QDC mold allows multiple high precision nesting die cutting to be achievable.

Applications:

This machine is well-suited for industries that require precision die cutting for materials like plywood, wood, and other specialized molds. It is particularly useful in: