Wide Thickness Range (8-35mm): This machine is built to process thicker, heavy gauge materials ranging from 8mm to 35mm. This makes it suitable for industries working with large, rigid metal plates, ensuring they are leveled and flattened to exact specifications.

Large Roll Diameter (180mm): With a 180mm roll diameter, this machine offers the necessary force to handle heavy sheets while ensuring high precision leveling. The increased roll size improves the machine’s ability to handle large volumes of material without causing deformation or excessive wear.

Advanced Servo Motor-Driven Adjustment: The four-point automatic leveling roller gap adjustment is powered by servo motors, ensuring consistent, precise adjustments during operation. This advanced system automatically adjusts to the thickness of the material, reducing the need for manual input and ensuring that each part is leveled with high precision.

Optimal for Heavy Blanks and Sheets: This leveling machine is designed specifically to handle heavy-duty applications, making it ideal for industries such as construction, automotive, and industrial machinery. It ensures that large metal plates are leveled with no loss of flatness, ensuring that they are ready for subsequent processes like welding, cutting, or assembly.

Wide Width Capacity (400-3800mm): The wide working width (up to 3800mm) enables the machine to process large sheets and blanks, making it versatile enough for a variety of manufacturing processes. This feature is beneficial for large-scale operations that require high throughput.

Efficient and Consistent Leveling: The 15 leveling rolls (7 upper, 8 lower) ensure even pressure distribution across the material, producing consistent and high-quality results across the entire surface. The rollers provide precise flattening and minimal distortion.

Heavy Gauge Metal Processing: This machine is perfect for leveling heavy metal plates (8-35mm thick) used in various industries, including steel fabrication, machinery manufacturing, and heavy-duty equipment production. It ensures precise and consistent flattening, even for tough materials.

Steel Structures and Construction: Ideal for processing steel plates used in structural applications, building frameworks, and bridges, ensuring that the materials are flat and ready for precise assembly.

Automotive Manufacturing: Used for leveling chassis, automotive body panels, and other heavy automotive parts, this machine ensures that parts are free from distortion and can be accurately welded or assembled.

Heavy Equipment Manufacturing: Suitable for machinery components and construction equipment parts that require accurate leveling for assembly and manufacturing processes. This includes parts used in the mining, agriculture, and industrial machinery sectors.

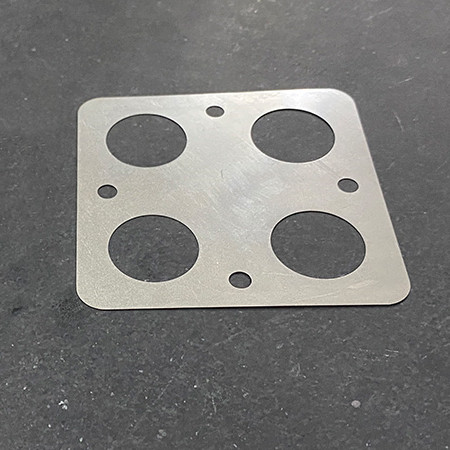

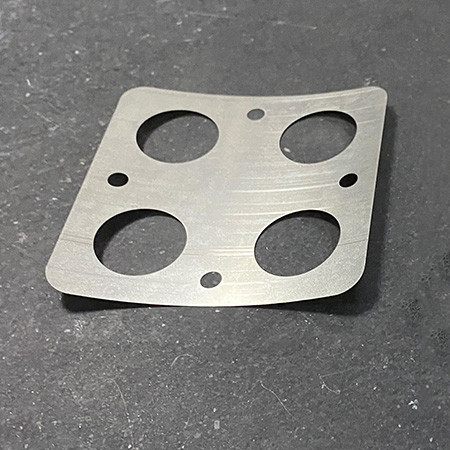

Industrial Sheet Metal Processing: The machine is versatile for general industrial applications, such as metal enclosures, tooling, and fixtures, that require precision leveling for high-quality fit and function.

Heavy-Duty Performance: With its ability to handle thicker, heavier materials (8-35mm), this machine is built for tough industrial environments. The 180mm roll diameter provides the necessary force for handling large, rigid materials with precision.

Automatic Servo Motor Adjustment: The four-point automatic leveling roller gap adjustment is controlled by servo motors, allowing for precise, continuous adjustments without manual intervention. This reduces the risk of error and enhances operational efficiency.

Increased Efficiency and Productivity: The automatic adjustment and large roll diameter ensure the machine can handle large, heavy plates quickly and efficiently, increasing throughput and minimizing downtime between processes.

Consistent Quality: The 15 leveling rolls and automatic gap adjustment ensure even pressure distribution and precise leveling, leading to consistent, high-quality results every time. This minimizes rework and reduces material waste.

Cost Savings: The combination of automatic adjustment, heavy-duty performance, and minimal manual labor helps reduce operational costs over time. The machine also contributes to better material utilization by ensuring parts are properly flattened before further processing.