MK-400PLUS Fully Automatic 5-Axis Complex Insert Grinder

Technical Specifications

| Parameter | Specification |

| Minimum Inscribed Circle | 3.5 mm (equilateral triangle), 4.7 mm (other shapes) |

| Maximum Circumscribed Circle | 45 mm |

| Maximum Insert Thickness | 15 mm (Can process up to 3 pieces of 4.76 mm simultaneously) |

| Main Spindle Motor | 7.5 kW 3-phase induction motor, V3 class |

| Tailstock Clamping Pressure | Max. 10 kN (at 7 MPa hydraulic pressure) |

| Machine Dimensions | 2,475 mm (W) × 2,250 mm (D) × 2,160 mm (H) |

| Machine Weight | 5,500 kg |

| Power Supply | AC 380V (50/60Hz), 25 kVA |

| Air Supply | ≥ 0.5 MPa, Air Consumption: 250 N/min |

| Hydraulic Pressure | Max. 7 MPa |

MK-400PLUS High Precision CNC Grinding Machine

Fully Automatic Insert Peripheral Grinder

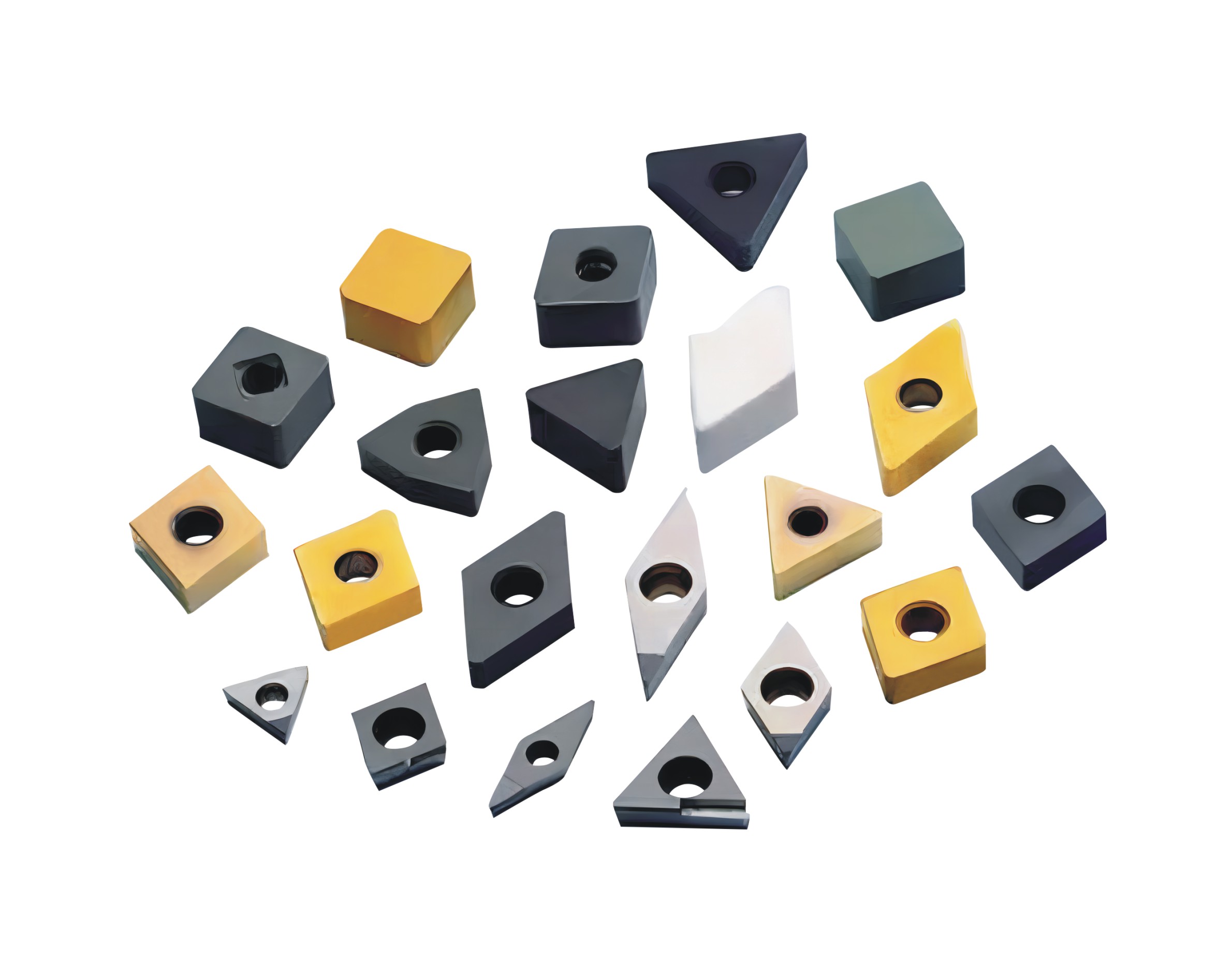

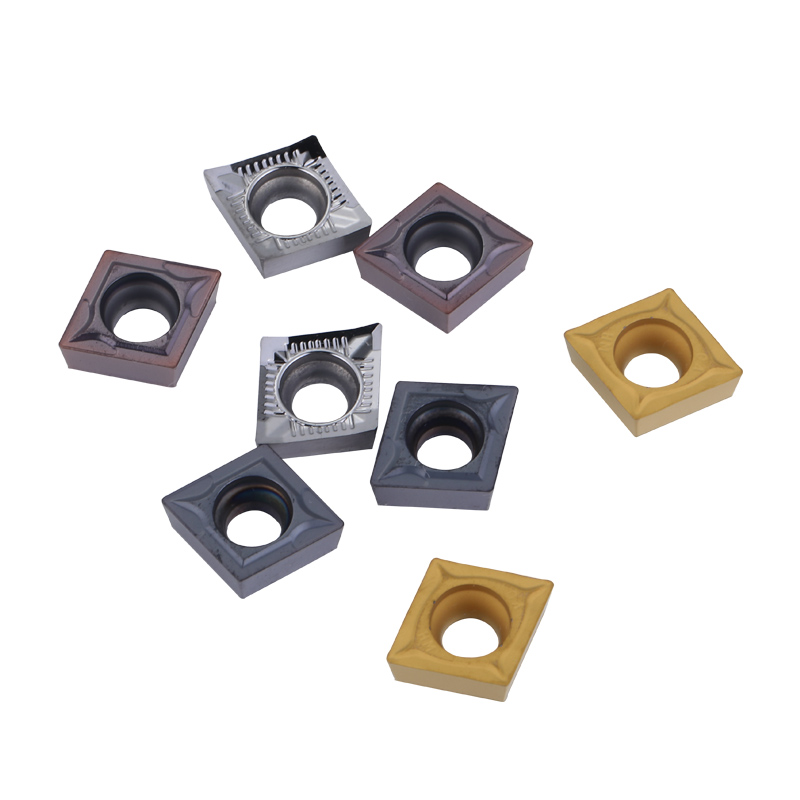

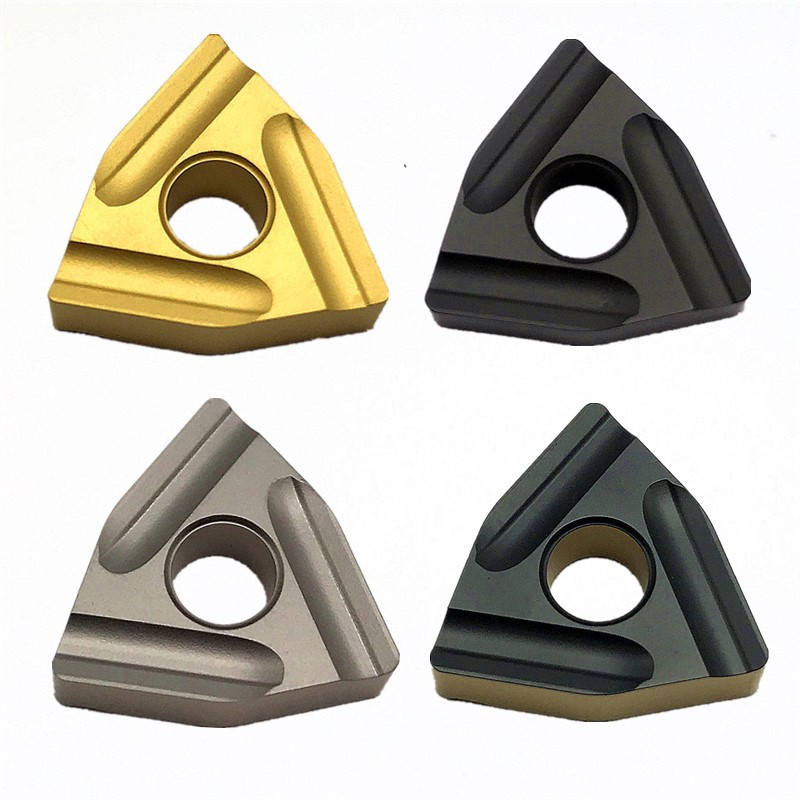

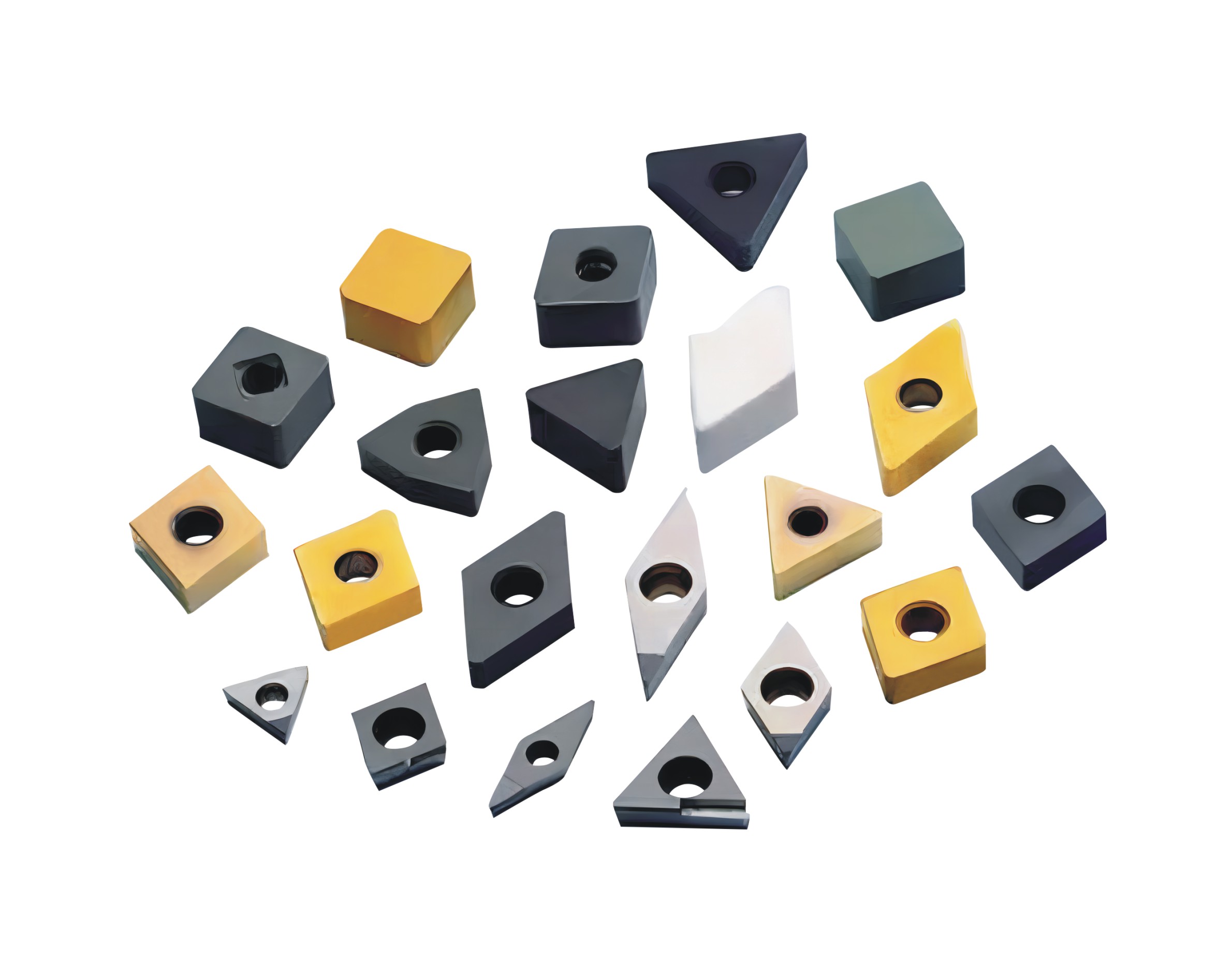

For Carbide, Cermet, Ceramic, CBN, and PCD Inserts

The MK-400PLUS is a state-of-the-art, fully automatic 5-axis CNC grinding machine designed specifically for high-precision peripheral grinding of indexable inserts. Supporting materials such as carbide, cermet, ceramic, CBN, and PCD, this advanced solution delivers superior automation, high efficiency, and exceptional accuracy for both standard and complex insert geometries.

Application Scope

Peripheral grinding of indexable inserts

Single-side land grinding for standard inserts

Optional 3D profile grinding

Suitable for large-scale production and flexible manufacturing systems

Supported Materials:

Key Features

Fully Automatic Operation

Full periphery and land grinding in one clamping

Robotic 3-axis material handling system with tray loading/unloading

Intelligent in-process measurement and correction system

Advanced 5-Axis Control

X-axis (left-right oscillation)

Y-axis (feed motion)

A-axis (workpiece rotation)

C-axis (workpiece angle adjustment: -91° to +91°)

V-axis (grinding wheel cleaning)

W-axis (blade positioning)

Maximum of 9 axes controlled simultaneously for complex profile machining and optimal flexibility.

Precision & Performance

Min. Inscribed Circle: 3.5 mm (Triangle), 4.7 mm (Others)

Max. Circumscribed Circle: 45 mm

Max. Insert Thickness: 15 mm (supports up to 3 inserts of 4.76 mm simultaneously)

Main Spindle Motor: 7.5 kW, high-stability, 3-phase induction

Grinding Wheel Dressing Motor: 1.5 kW electric spindle

High-Rigidity Structure

Heavy-duty frame ensures mechanical stability and micron-level accuracy

Reduced vibration during high-speed operations

Consistent results even under heavy load

User-Friendly Software & Interface

Compatible with ToolLab software (standard)

Easy programming for beginners; full customization for experts

Supports Evo platform tools and hardware

Fast transition for users of other grinding systems

Integrated Measurement & Quality Control

Pre-processing material dimension detection

Post-processing inscribed circle verification

Automatic correction and defect exclusion

Optional 3D measuring probe

Dressing & Blade Centering

Side dressing capability for wheel longevity

Manual and automatic blade positioning system

One block can be installed for precise blade centering

Safety, Maintenance, and Energy Efficiency

CE-compliant full-enclosure design

Centralized lubrication system

Compact footprint: 2475 mm × 2250 mm × 2160 mm

Machine Weight: 5,500 kg

Total Electrical Load: 25 kVA @ AC 380V

Air Requirement: ≥ 0.5 MPa, 250 N/min consumption

Advantages at a Glance

Grind periphery and land in one setup

Suitable for superhard materials including PCD and CBN

High throughput with minimal operator input

Flexible configuration for a wide range of insert shapes

Seamless software and hardware integration

In-process error detection and correction

Rugged, space-saving design

Ideal Use Cases

Indexable insert manufacturers

High-precision cutting tool production

High-mix, high-volume operations

Manufacturers seeking lights-out automation

The MK-400PLUS sets the new standard in insert grinding, combining intelligent design, world-class precision, and full automation to meet the evolving needs of modern tool manufacturing.