MK-400PLUS Indexable Insert Peripheral Grinding Machine

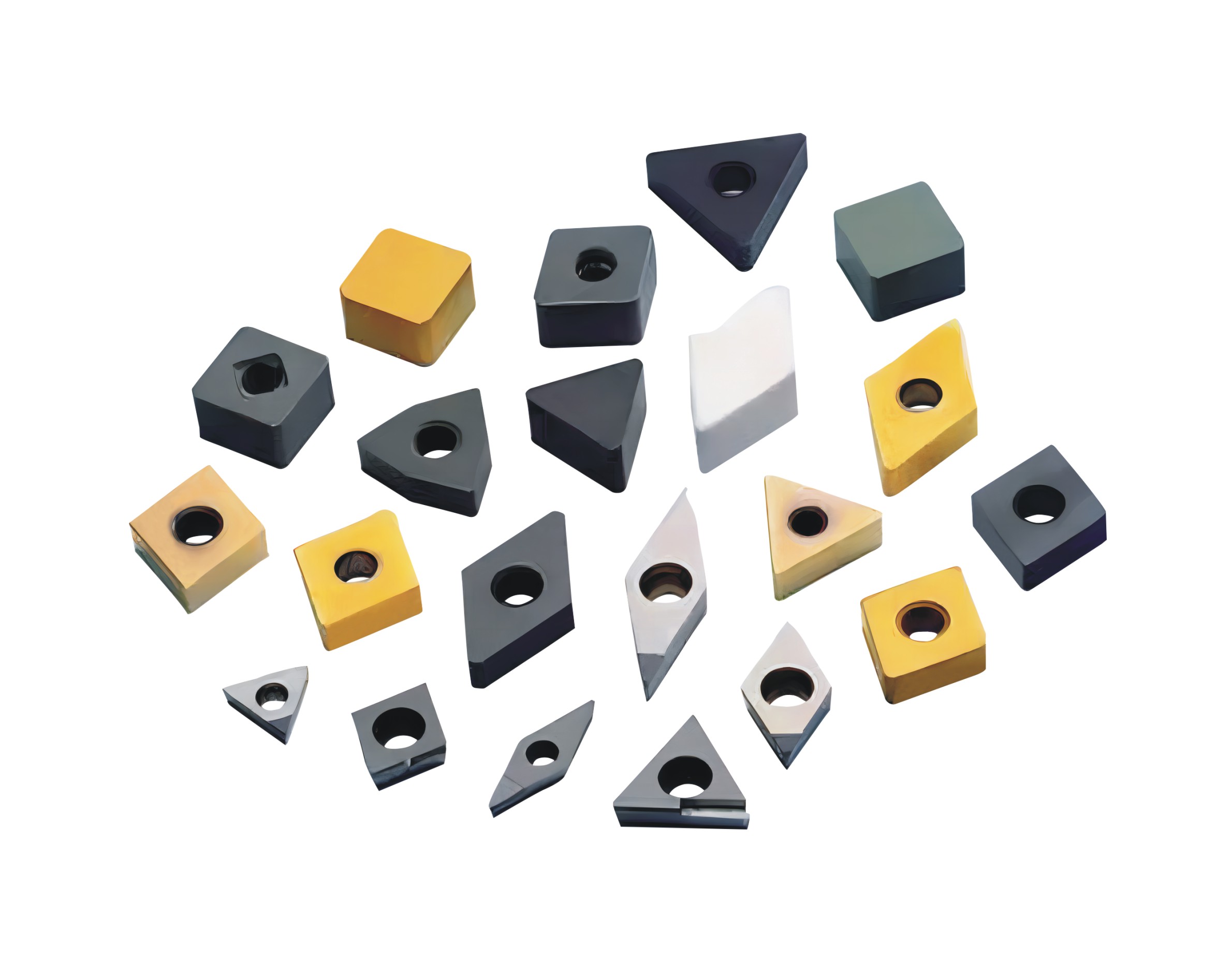

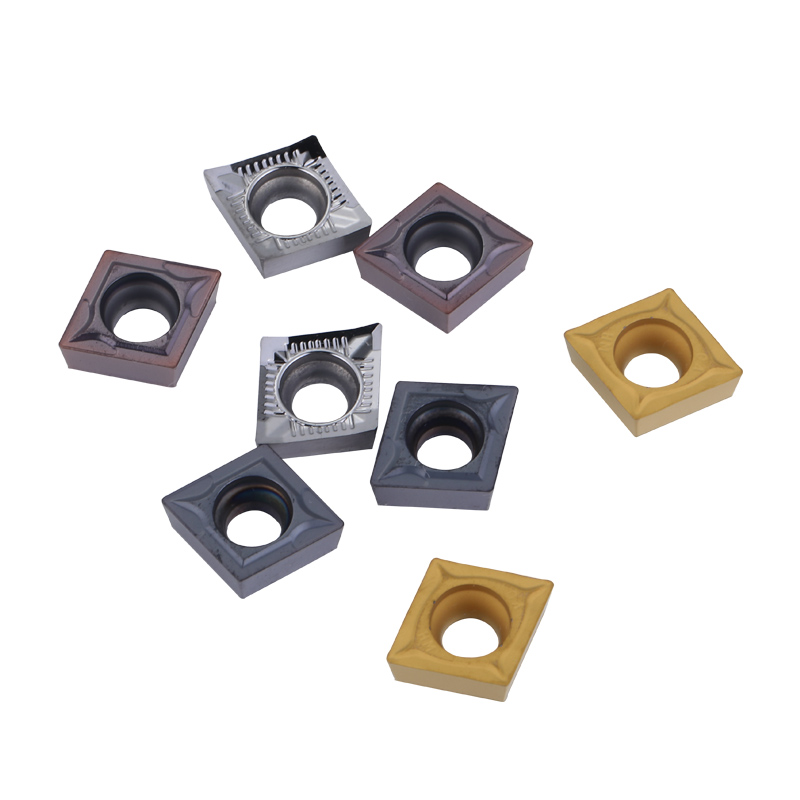

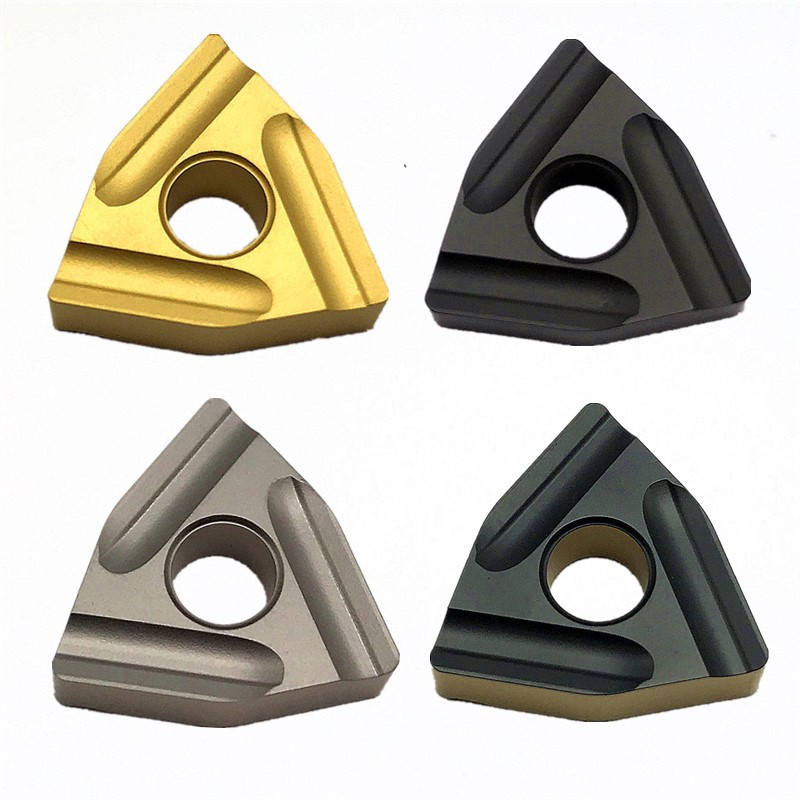

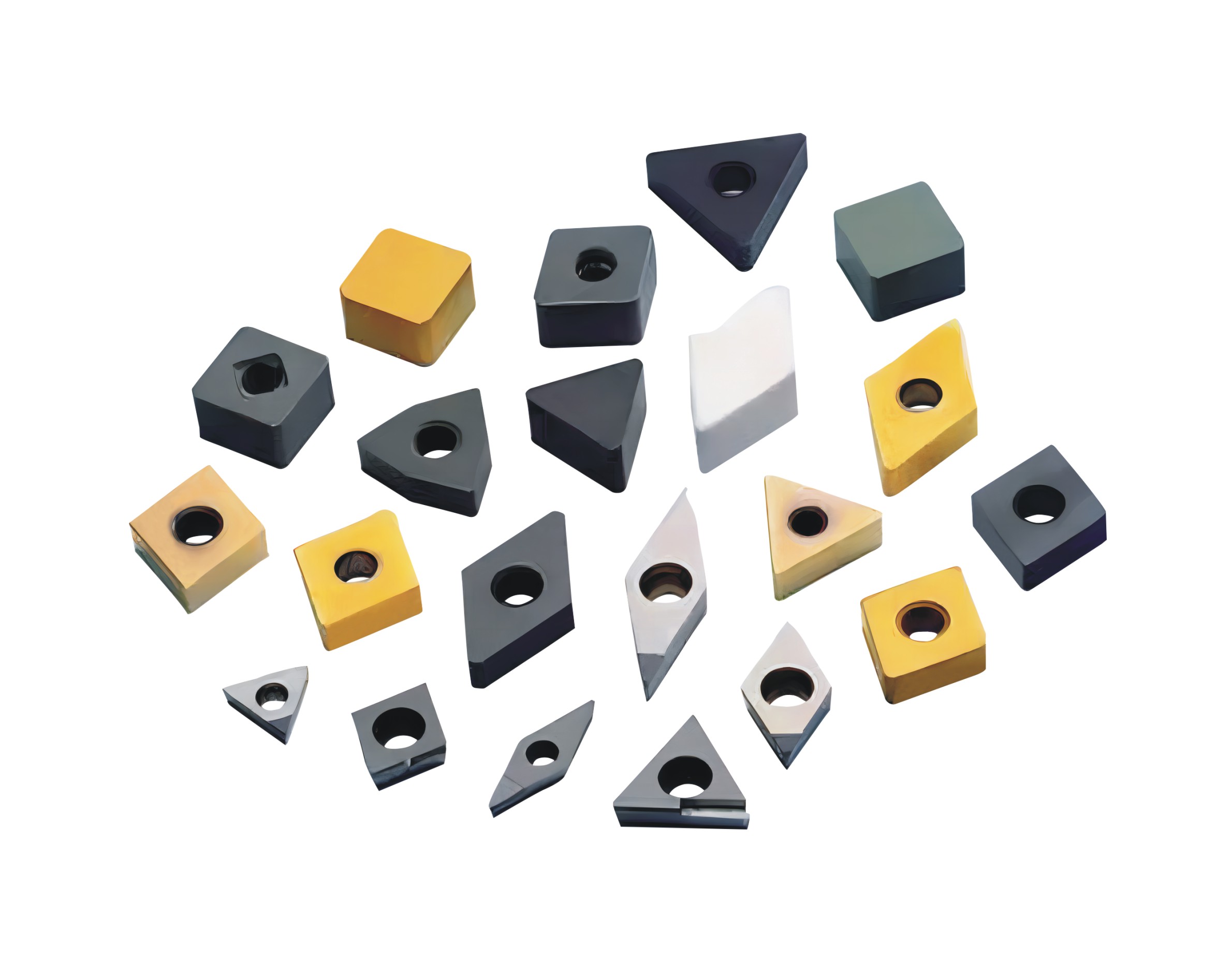

Fully Automatic 5-Axis CNC Insert Grinder for Carbide, Cermet, Ceramic, CBN, and PCD

Product Overview

The MK-400PLUS is a state-of-the-art fully automatic 5-axis CNC grinding machine expertly engineered for high-precision peripheral grinding of indexable inserts. It is specifically designed to handle superhard materials including carbide, cermet, ceramic, cubic boron nitride (CBN), and polycrystalline diamond (PCD). This machine enables manufacturers to produce standard and complex insert geometries with unmatched accuracy, efficiency, and automation.

Combining advanced hardware, robust structural design, and intelligent software, the MK-400PLUS offers manufacturers a complete solution for precision insert grinding in today’s competitive tooling market.

Key Applications

Peripheral grinding of indexable inserts

Single-side land grinding of standard series inserts

Complex 3D profile grinding (optional with advanced software)

Processing materials including carbide, cermet, ceramic, CBN, and PCD

High-volume and high-mix insert production

Automated manufacturing lines with robotic material handling

Technical Specifications

| Parameter | Specification |

| Minimum Inscribed Circle | 3.5 mm (Equilateral Triangle), 4.7 mm (Other) |

| Maximum Circumscribed Circle | 45 mm |

| Maximum Insert Thickness | 15 mm (up to 3 pieces of 4.76 mm thickness simultaneously) |

| Main Spindle Motor | 7.5 kW, 3-phase induction motor, V3 insulation class |

| Grinding Wheel Dressing Motor | 1.5 kW electric spindle |

| Tailstock Clamping Pressure | Max 10 kN at 7 MPa hydraulic pressure |

| Machine Dimensions (WxDxH) | 2475 × 2250 × 2160 mm |

| Machine Weight | 5500 kg |

| Power Supply | 25 kVA, AC 380V, 50/60 Hz |

| Compressed Air Requirement | ≥0.5 MPa, 250 N/min |

| Hydraulic Pressure | Max 7 MPa |

Axis Configuration & Control

X-axis: Left-right oscillation with automatic centralized lubrication

Y-axis: Feed motion with direct-drive and lubrication

A-axis: Workpiece rotation with extended continuous swivel range

C-axis: Table angle adjustment from -91° to +91°

V-axis: On-line grinding wheel cleaning

W-axis: Blade positioning (manual fine adjustment)

Robotic axes: 3-axis linear robotic arm for material handling (tray transport and insert loading/unloading)

Up to 9 simultaneous CNC control axes ensure maximum flexibility and precision in complex insert grinding.

Core Features & Benefits

Fully Automatic Operation

The MK-400PLUS automates peripheral grinding and land grinding in a single clamping cycle, drastically reducing setup time and improving accuracy. Its robotic 3-axis loading system enables continuous lights-out production, significantly increasing throughput while minimizing operator involvement.

High Precision & Rigidity

Constructed with a heavy-duty frame and precision components, the MK-400PLUS maintains micron-level repeatability. This rigidity reduces vibrations and thermal distortions during heavy-duty grinding, ensuring consistent surface finish and dimensional accuracy even during extended runs.

Advanced Measurement & Quality Control

Equipped with an integrated measurement system, the machine verifies material dimensions before processing and performs inscribed circle checks post-grinding. Defective parts are automatically rejected or sent for regrinding, and correction data is fed back into the process for continuous quality improvement. Optional 3D measuring probes provide enhanced geometric verification.

Flexible Software & User Interface

Compatible with Agathon’s ToolLab software, the MK-400PLUS offers an intuitive user interface for programming and operation. Novice operators can quickly learn to operate the system with guided setup, while experienced programmers have full access to advanced 5-axis path programming, macros, and custom workflows.

Grinding Wheel Dressing & Blade Positioning

The machine includes an electric spindle-driven dressing unit to maintain grinding wheel shape and sharpness during production. Manual and automatic blade positioning ensures inserts are precisely centered for consistent grinding results.

Safety & Maintenance

Designed with a fully enclosed, CE-compliant safety cabin, the MK-400PLUS protects operators from dust and noise. Centralized lubrication reduces maintenance efforts, while its compact footprint fits efficiently into modern manufacturing environments.

Ideal Users & Applications

Indexable insert manufacturers specializing in carbide, CBN, PCD, and cermet tools

Toolmakers requiring automated, high-volume, and high-precision grinding

Manufacturers producing complex insert geometries and multi-edge tools

Companies seeking lights-out manufacturing and automation in grinding processes

Summary

The MK-400PLUS is a premium, fully automatic 5-axis CNC grinding machine that empowers manufacturers to deliver superior quality indexable inserts with higher efficiency and less manual intervention. Combining intelligent automation, precision mechanics, and robust software integration, it sets a new benchmark for insert grinding technology.