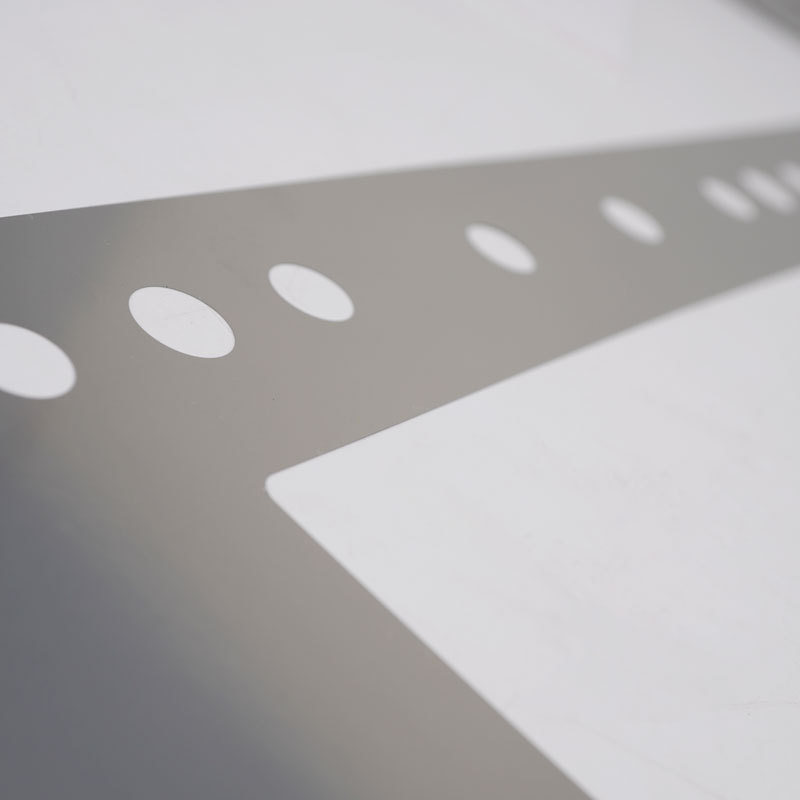

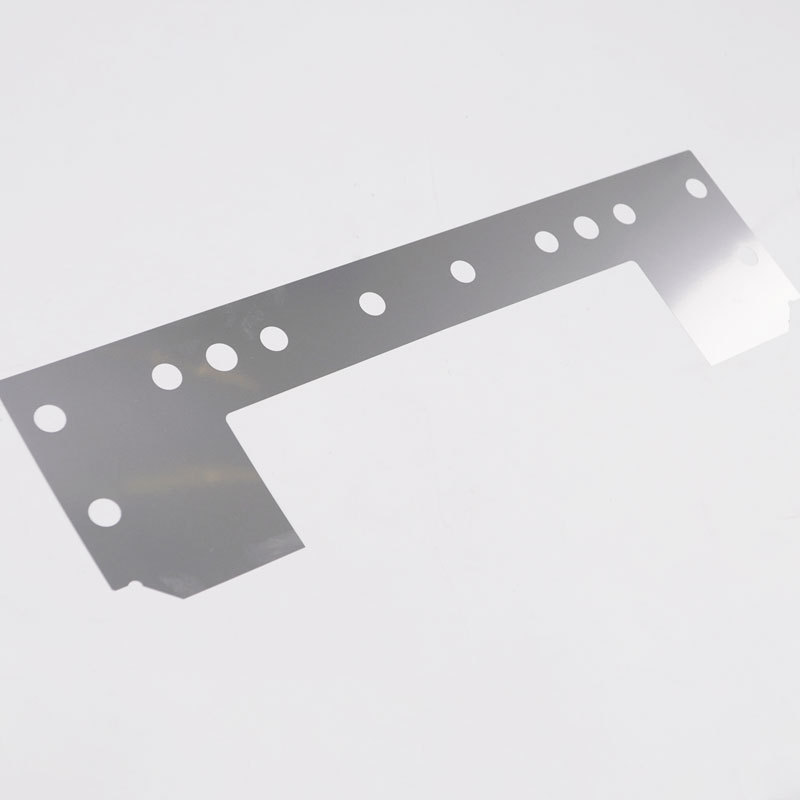

Precision Laser Cutting Services for Flat Washers, Shims, and Spacers

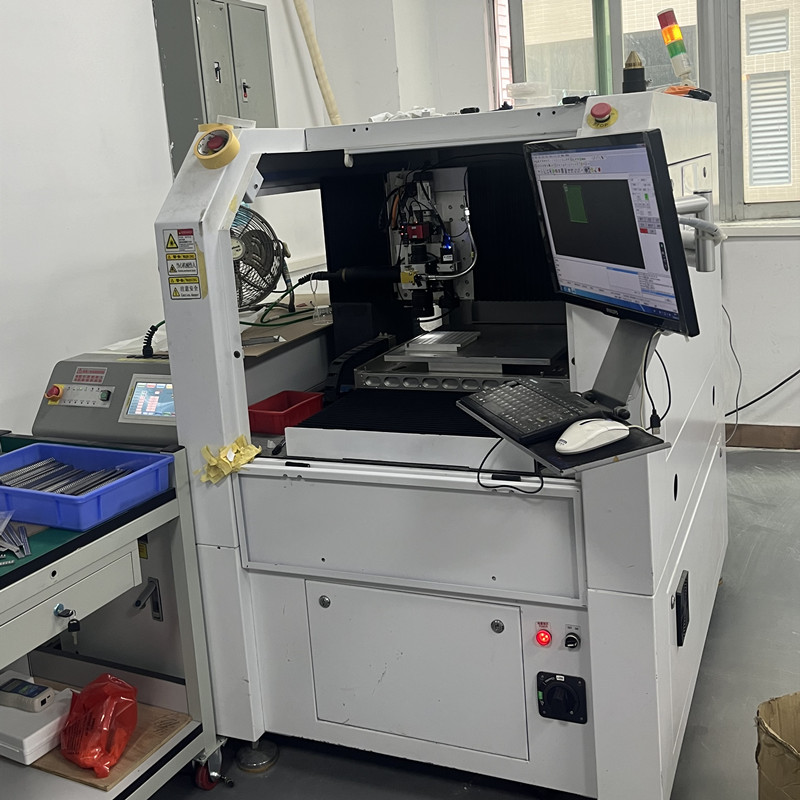

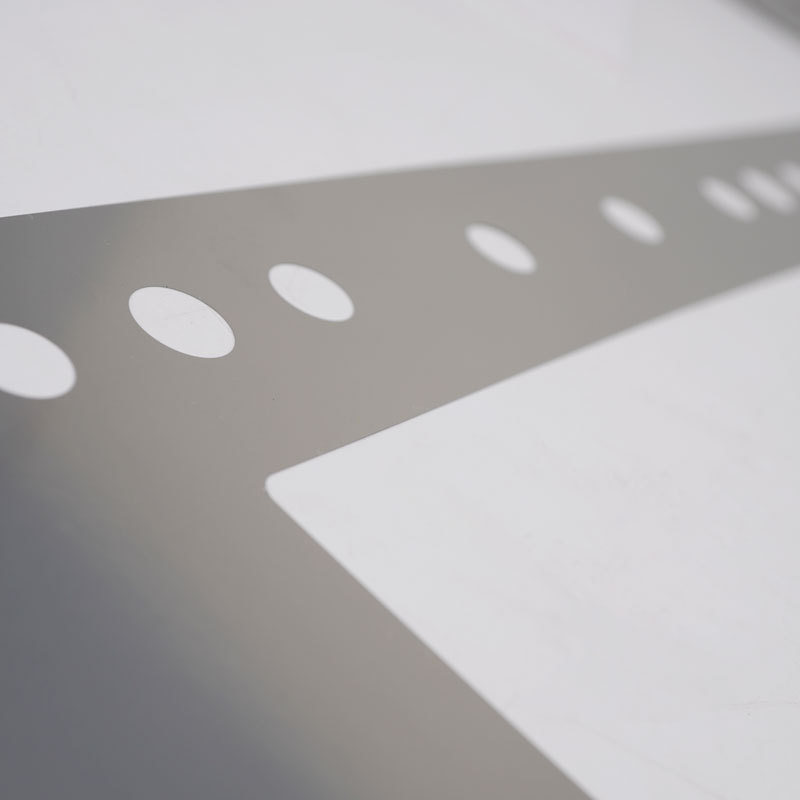

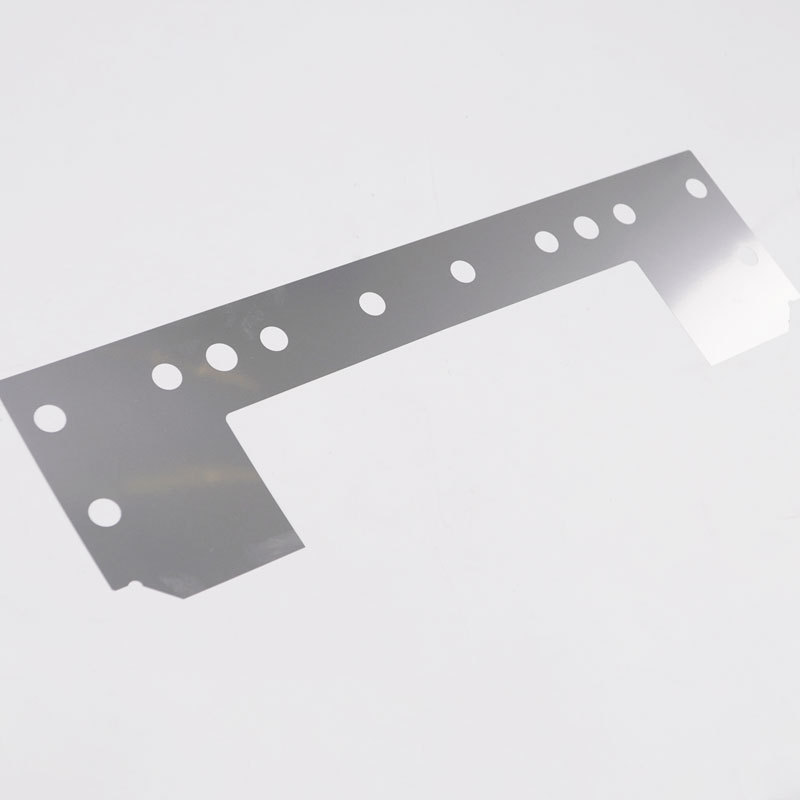

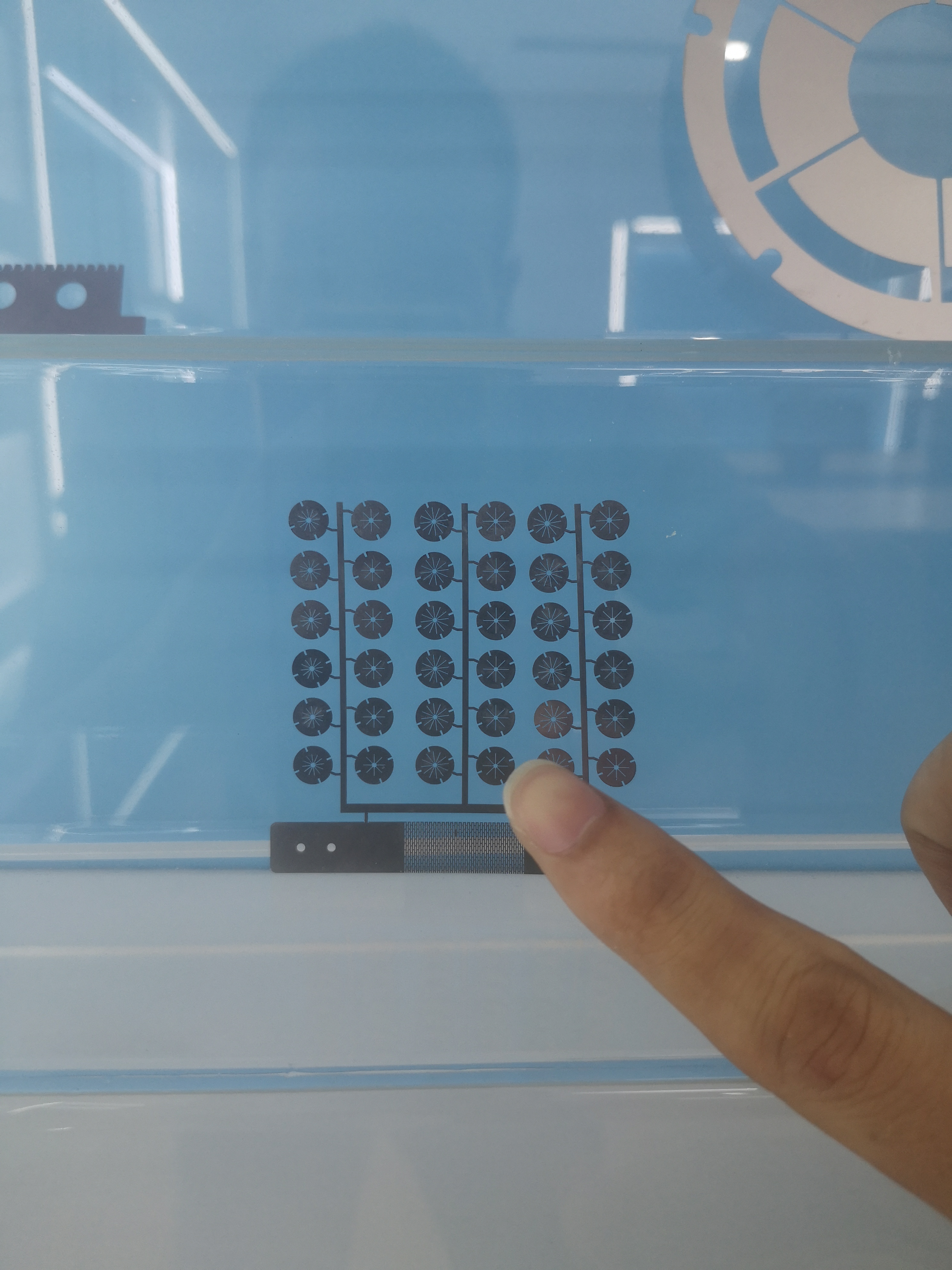

Stencils Unlimited offers high-quality, customized precision flat washers, shims, and spacers made from a variety of materials using advanced laser cutting technology. This service delivers ultra-precision products with burr-free and stress-free finishes, suitable for a range of industrial and manufacturing applications.

Key Features of Our Service:

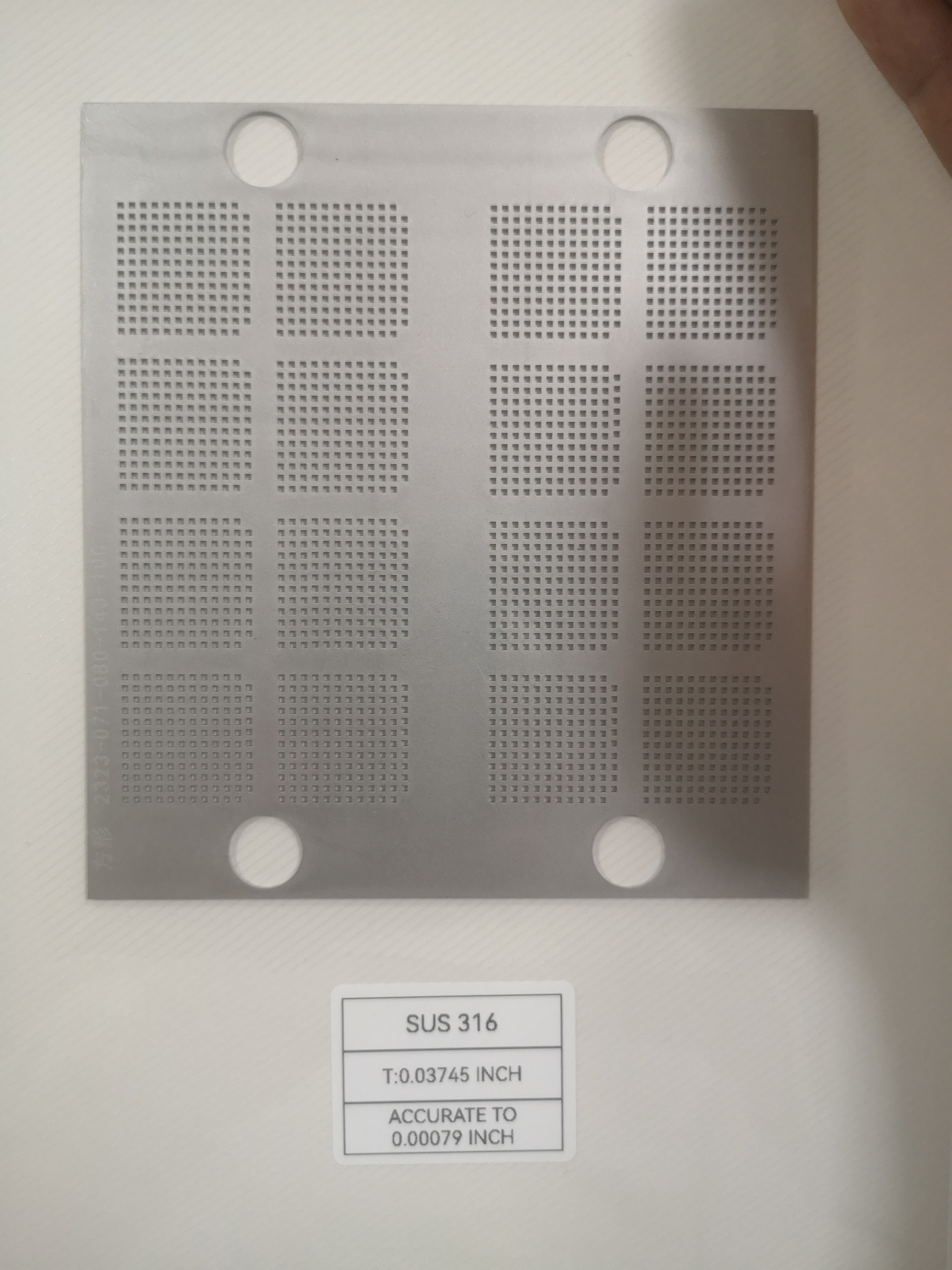

Precision Laser Cutting Technology: We use state-of-the-art laser cutting technology, which ensures highly accurate cuts and fine detail down to a minimum feature size of 0.002" (50 microns).

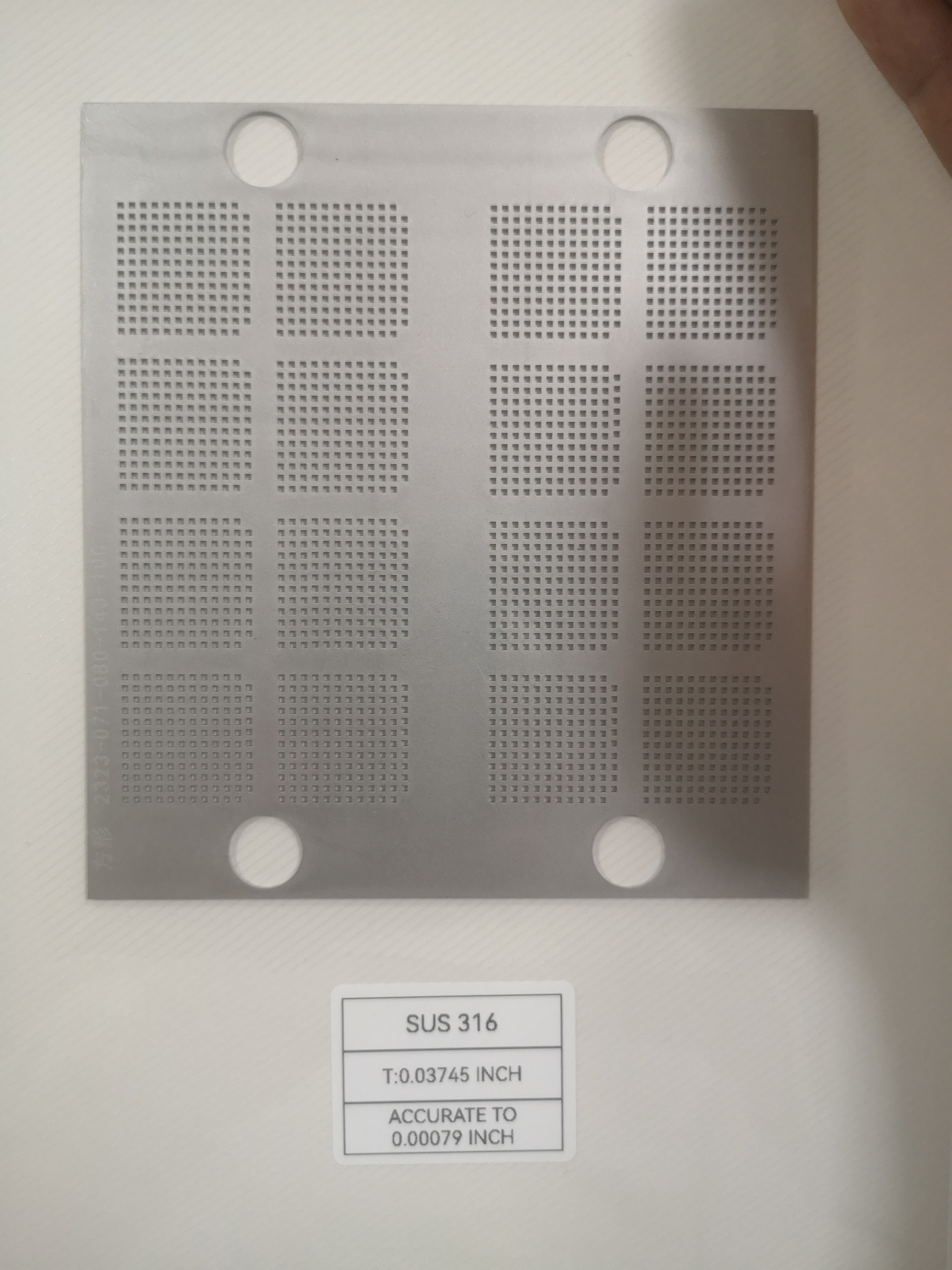

Materials & Thickness Options: Available in stainless steel and other materials, with thicknesses ranging from 0.002" to 0.020".

No Tooling Required: Unlike traditional manufacturing methods, our laser cutting process does not require costly tooling or complex setups, making it more efficient and cost-effective.

No Minimum Quantity: Whether you need a single custom washer, shim, or spacer, or require a large batch, there are no minimum order quantities. This makes us a perfect fit for prototypes, small runs, and large-scale production.

Short Lead Times: With a fast lead time of just 24-48 hours, we are able to deliver precision components quickly to meet urgent production schedules.

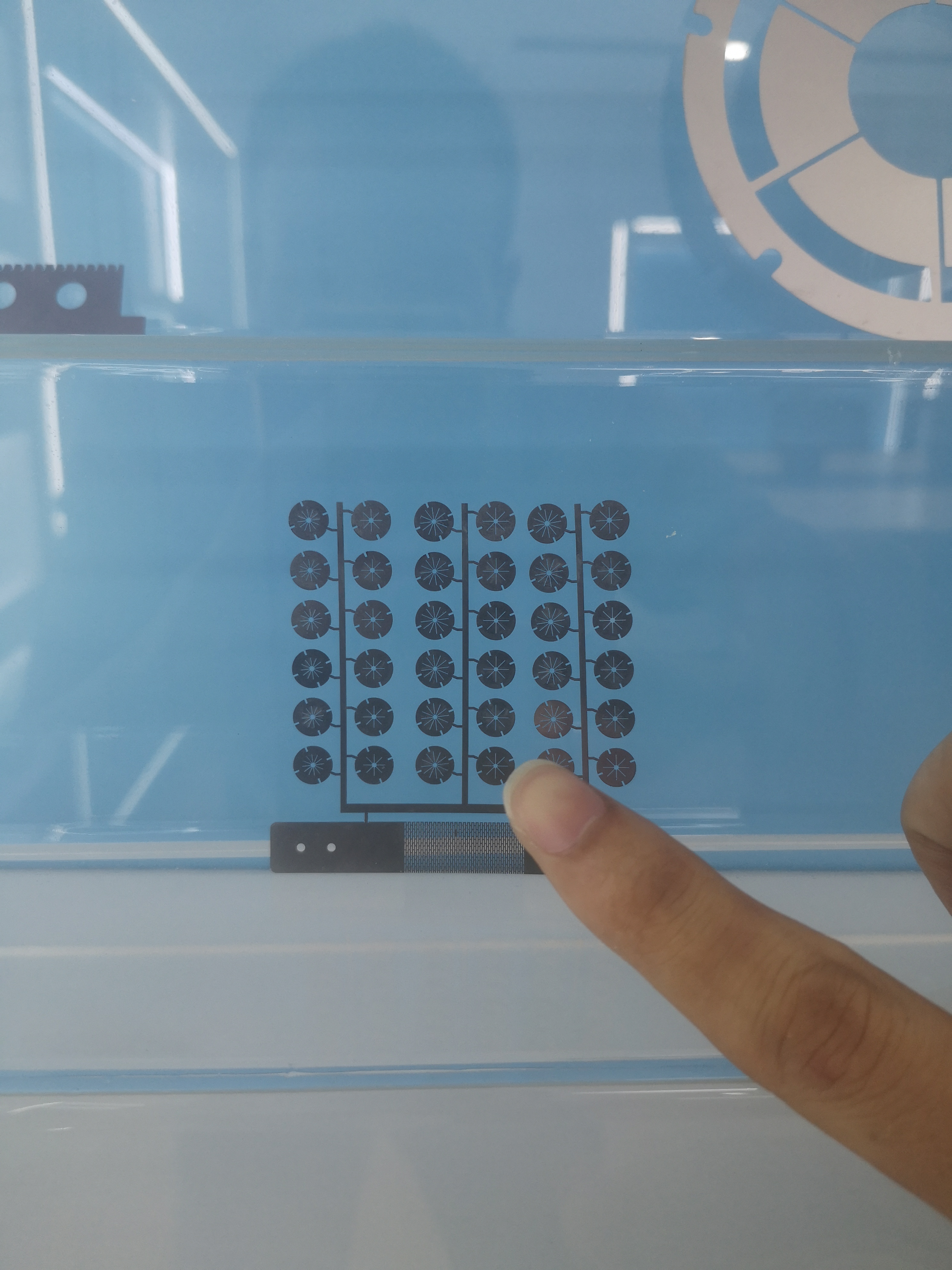

Customization & Flexibility: You can specify the size, shape, material, and thickness of your washers, shims, and spacers. Laser engraving options are also available for additional customization, such as adding reference numbers or logos.

Applications:

Flat Washers: Used to distribute the load of a threaded fastener, such as a bolt or nut, and prevent damage to the surface.

Shims: Used for spacing or leveling parts, shims are commonly applied in machinery assembly, automotive, aerospace, and manufacturing industries to ensure tight tolerances.

Spacers: Essential for creating precise distances between components, spacers are used across various fields, including electronics, automotive, and mechanical engineering.

Specifications:

Materials: Stainless Steel (other materials available upon request)

Thicknesses: 0.002" - 0.020"

Minimum Feature Size: 0.002" (50 µm)

Maximum Size: 22.5" x 29"

Aperture Tolerance: Within 0.00025"

Lead Time: 24-48 hours

Engraving: Yes (for added customization)

Benefits of Using Precision Laser Cutting:

Accuracy & Quality: With laser cutting, you achieve precise, consistent results, ideal for tight tolerance applications.

No Burrs or Stress: Our laser cutting process leaves a clean edge, without burrs or thermal stress, ensuring high-quality components.

Cost-Effective: No tooling is needed, and there are no minimum quantity requirements, reducing the cost and lead time for prototypes and small production runs.