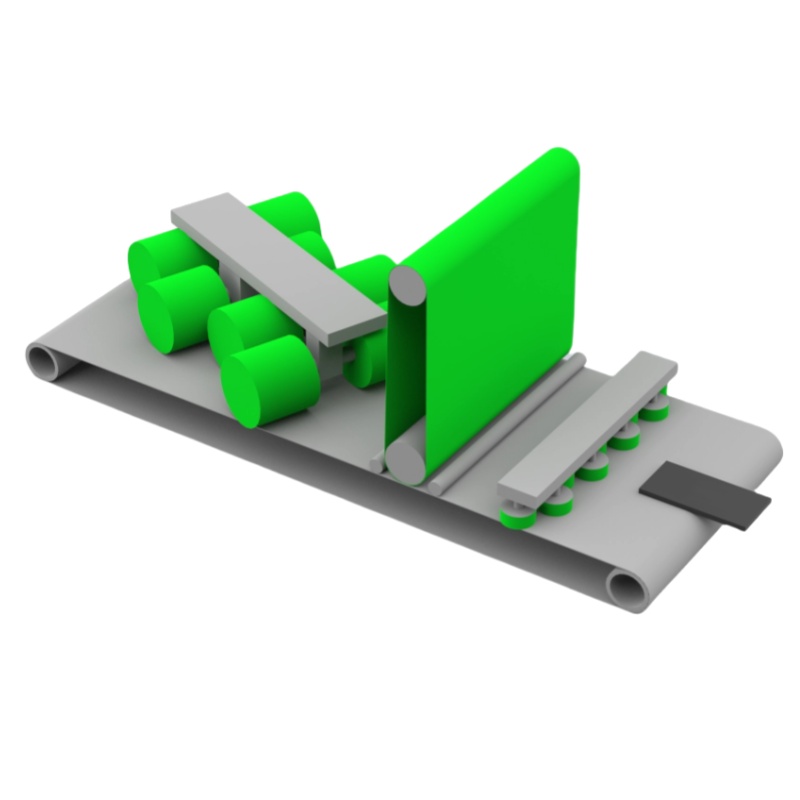

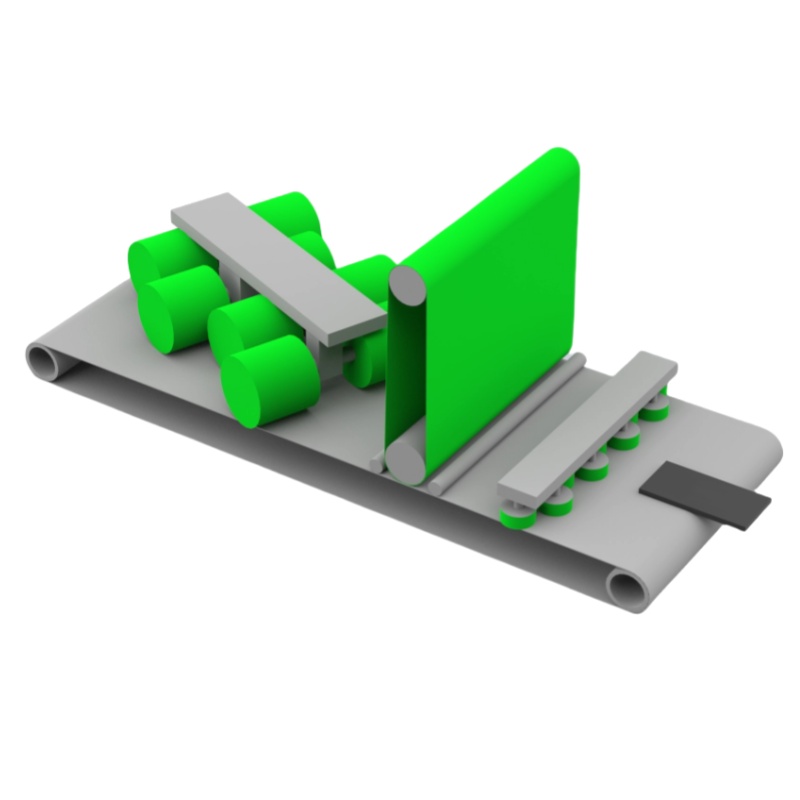

1350mm Deburring Machine for Plasma Cutting with Laser Oxide Removal and Heavy Slag Removal

Configuration: Steel Hammer Disc + Sanding Belt + Flap Wheel Brushes

This 1350mm wide heavy-duty deburring and finishing machine is specifically designed for plasma-cut and laser-cut sheet metal parts, delivering a complete solution for slag removal, oxide layer cleaning, deburring, edge rounding, and surface finishing.

With a powerful combination of a steel hammer deslagging unit, abrasive sanding belt, and flap wheel brushes, it ensures high efficiency and consistent surface quality even on the most challenging materials and thick parts.

Key Features:

Working width: 1350 mm

Processing thickness: 1.0 mm – 100 mm

Minimum part size: 60 × 60 mm

Station configuration:

– Steel hammer disc (deslagging unit) for heavy slag removal from flame and plasma-cut edges

– Sanding belt for general burr and oxide cleaning

– Flap wheel brushes for edge rounding (up to R2.0 mm) and surface finishing

Material compatibility: Carbon steel, stainless steel, galvanized steel, aluminum, etc.

Edge processing: Outer contours, inner holes, and corners with uniform rounding

Feeding system: Continuous feed belt with variable speed control

Control system: PLC with HMI touchscreen, programmable for different part types

Typical Applications:

Plasma- and flame-cut part post-processing

Laser-cut part oxide removal

Deburring of structural components and heavy sheet metal

Surface preparation for painting, powder coating, or welding

Machinery bases, frames, panels, steel structures

✅ Advantages:

All-in-one processing: deslagging + oxide removal + edge rounding + finishing

Steel hammer unit eliminates thick slag without damaging base material

Flap brushes give safe, rounded edges and aesthetic finishes

Modular system suitable for high-mix, low-volume or batch production

Improves downstream quality, safety, and coating adhesion

Reduces manual grinding labor and rework

Optional Add-ons:

Magnetic or vacuum workpiece holding system

Wet or dry dust collection system

Automatic thickness detection

Integration with upstream plasma or laser cutting line

Product Overview:

The MSP-DL1350 is a high-performance deburring, slag removal, and edge rounding machine specifically engineered for processing carbon steel sheet metal parts after laser cutting, plasma cutting, flame cutting, punching, or shearing. It integrates a dry steel hammer station, a sanding belt head, and eight multi-directional abrasive disc brush heads, delivering 360° processing for superior surface quality and consistent R-edge rounding.

This machine is a complete dry-processing system that removes heavy slag, laser oxide layers, burrs, and sharp edges in a single pass. It is ideal for applications in heavy fabrication, construction steel processing, machinery manufacturing, and similar industries demanding high throughput and flawless finishing.

⚙️ Key Processing Features:

✅ Heavy Slag Removal — Steel hammer disc brush station removes thick slag after thermal cutting

✅ Laser Oxide Film Removal — Sanding belt station cleans oxidation and residual burrs

✅ Edge Rounding & Deburring — Eight-disc planetary rotary brushes generate uniform R-radius on edges and holes

✅ Independent Stations — Each processing unit can be operated independently for specific needs

✅ Magnetic Conveyor Table — Strong permanent magnetic adsorption ensures part stability without fixtures

✅ Wet Dust Collection System — Efficient water-based dust removal with environmental filtration and safe air exhaust

Applications:

Laser oxide removal

Heavy slag removal (plasma/flame cut parts)

Deburring inner and outer edges

Edge rounding up to R2mm

Surface brushing and polishing

Pre-treatment before painting or welding

Working Principle:

Steel Hammer Station: Oscillating steel hammer discs strike and remove heavy slag and thick burrs.

Sanding Belt Station: Smooths surfaces, removes oxide films, and pre-polishes the material.

Planetary Brush Station: Eight abrasive disc brushes rotate and revolve in opposing directions to deburr and round all edges and inner holes, generating centrifugal action for a uniform R-radius.

All stations are modular and can function independently depending on the processing task.

Technical Specifications:

| Parameter | Specification |

| Max Processing Width | ≤1330 mm |

| Processing Thickness | 0.5 – 80 mm |

| Min Workpiece Size | 50 × 50 mm (solid parts) |

| Total Power | 45.5 kW |

| Abrasive Belt Size | Φ1910 × 1350 mm |

| Brush Disc Size | Φ300 × 400 mm |

| Feed Speed | 0.5 – 6 m/min (VFD adjustable) |

| Sanding Belt Speed | 18 m/s |

| Brush Rotation Speed | 8 – 26 m/s (VFD adjustable) |

| Brush Revolution Speed | 1 – 15 rpm (VFD adjustable) |

| Planetary Brush Heads | 1 planetary set, 8 rotating heads |

| Servo Precision – Thickness | 0.01 mm |

| Servo Precision – Compensation | 0.01 mm |

| Grinding Media | Steel hammer + Sand belt + Brushes |

| Dust Collection Volume | 5000 m³/h |

| Machine Dimensions | L4500 × W2300 × H2500 mm |

| Machine Weight | Approx. 6 Tons |

Main Components & Configuration:

Hammerhead Disc Unit: 9 pcs Φ162mm discs, 11kW motor

Abrasive Belt Grinding Unit: 1pc Φ185mm×1350mm, 15kW motor

Rotary Brush System: 8 rotating heads, 4 × 11kW motors

Servo Motors: For thickness adjustment and brush compensation (VEICHI)

Conveyor System: Magnetic rubber belt, 4kW motor with BKA87 reducer

Control System: VEICHI PLC + 7” Touchscreen HMI

Inverters: VEICHI brand for all motor speed controls

Dust Collection: Water-based wet filtration with high-pressure fan

Electrical Components: CHNT / NSK bearings

Advantages at a Glance:

High Efficiency – Continuous through-feed design supports mass production

Precision Processing – Consistent R-edge rounding and no film damage on coated parts

Cost Reduction – Greatly reduces manual grinding labor and per-unit processing costs

️ Safe & Eco-Friendly – Closed-loop wet dust removal system ensures safe operation and green manufacturing

Flexible Functionality – Each unit operates independently for targeted tasks