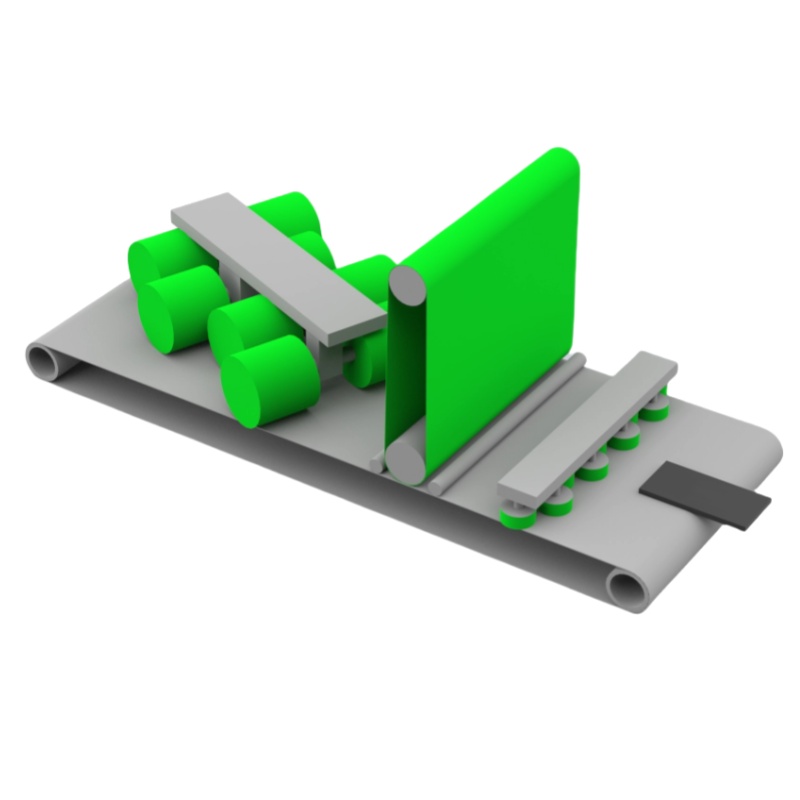

1600mm Deburring Machine for Shearing with Laser Oxide Removal and Heavy Slag Removal

Steel Hammer Disc + Sanding Belt + Flap Wheel Brushes

This 1600mm wide deburring machine is specially designed for sheared metal parts requiring heavy slag removal, laser oxide removal, and precise deburring with edge rounding. Combining the powerful impact action of a steel hammer disc, the efficiency of a sanding belt, and the finesse of flap wheel brushes, it delivers superior surface finishing on stainless steel, carbon steel, aluminum, copper, and various non-ferrous metals. The equipment ensures complete burr and slag removal, uniform R-arc edge rounding, and a polished, oxide-free surface in one continuous pass.

Key Features

Heavy Slag Removal: The steel hammer disc brush station effectively knocks off heavy slag and large burrs from sheared edges and surfaces.

Laser Oxide Removal: The sanding belt removes oxide layers formed during laser cutting and shearing, preparing surfaces for further processing.

Edge Rounding & Polishing: Flap wheel brushes provide consistent edge rounding and metal finishing, enhancing both aesthetics and safety of finished parts.

Wide Material Compatibility: Suitable for stainless steel, carbon steel, aluminum, copper, and other non-ferrous metals.

Independent and Combined Operation: Steel hammer disc, sanding belt, and flap wheel brush stations can operate independently or together for tailored processing.

Secure Workpiece Fixation: Equipped with a vacuum hold-down system to stabilize workpieces (minimum size 50mm × 50mm), allowing tooling-free pass-through processing.

Adjustable Processing Parameters: Variable frequency drives control conveyor speed, brush rotation speed, sanding belt speed, and brush revolution speed for process optimization.

Efficient Dust Collection: Integrated wet dust collector with high-flow fans captures and filters grinding dust, promoting a clean and safe working environment.

User-Friendly Controls: PLC with touchscreen HMI for intuitive operation and monitoring.

Typical Applications

Deburring, slag removal, and finishing of sheared metal sheets and components.

Laser oxide removal to improve surface quality.

Edge rounding for safer handling and improved product aesthetics.

Surface preparation before painting, coating, or assembly.

Technical Specifications

Processing Width: ≤1600mm

Processing Thickness: 0.5mm to 80mm

Minimum Processing Size: 50mm × 50mm (solid workpieces)

Total Machine Power: Approx. 75KW

Steel Hammer Disc Size: Φ162mm

Sanding Belt Size: Φ2400mm × 1600mm

Flap Wheel Brush Diameter: 350mm × 550mm

Conveyor Speed: 0.5 to 6 m/min, frequency adjustable

Dust Extraction Volume: Approx. 5000 m³/h

Machine Dimensions: Length 4800mm × Width 2600mm × Height 2550mm

Machine Weight: Approx. 7 tons

Product Overview:

This heavy-duty 1600mm wide deburring and finishing machine is engineered for comprehensive processing of metal sheets — including slag removal, edge rounding, deburring, brushing, and polishing. It is ideal for handling burrs and slag resulting from stamping, shearing, laser cutting, plasma cutting, and flame cutting.

The machine integrates three key processing modules:

Steel Hammer Disc Brush Station for knocking off heavy slag,

Wide Sanding Belt Station for smoothing and grinding, and

Eight-Axis Planetary Roller Brush Station for full 360° edge and hole deburring with a uniform R-radius finish.

Whether processing stainless steel, carbon steel, aluminum, copper, or non-ferrous metals, this system guarantees high-quality results, safe operation, and maximum productivity — making it a reliable solution for industrial-scale surface treatment.

Key Functions & Capabilities:

✅ Slag Removal (flame/plasma/laser cutting residue)

✅ 360° Edge Rounding (adjustable R radius)

✅ Surface Brushing and Hairline Finishing

✅ Burr Removal on holes and contours

✅ Protective Film Safe: No damage to coated sheet metals

✅ Polishing and Surface Conditioning

✅ Oxide Layer Removal

⚙️ Working Principle:

Steel Hammer Disc Brush Station

Sanding Belt Station

Planetary Roller Brush Station (8 Brushes)

Adjacent roller brushes counter-rotate while the assembly revolves around the workpiece.

This generates centrifugal grinding, cutting, scraping, and filing forces, producing consistent small R arc effects on all edges and holes.

Burrs are fully removed even from intricate shapes without affecting dimensional accuracy.

Independent Operation

Steel hammer for edge slag removal

Sanding belt for surface brushing or polishing

Roller brushes for 360° deburring without film damage

Vacuum + Dust Control System:

Equipped with a high-power vacuum bed for holding parts ≥50mm × 50mm (0.5–10mm thick, no holes) without fixtures.

Optional custom fixtures available for special workpieces.

Conveyor is frequency-controlled for adjustable feed speed.

Wet-type dust collector captures grinding debris using a high-flow fan and water spray filtration, ensuring:

Advantages of the Equipment:

High Throughput: Pass-through design with continuous feeding supports batch processing.

Superior Product Quality: Consistent surface treatment, better than manual methods.

Lower Processing Costs: Reduces cost per square meter of treated sheet metal.

️ Safe & Eco-Friendly: Dust-free working environment and recyclable waste metal.

Main Technical Specifications:

| Parameter | Specification |

| Max Processing Width | ≤1580 mm |

| Processing Thickness | 1 – 80 mm (solid) |

| Min Workpiece Size | 50 × 50 mm (0.5–10 mm thick, no holes) |

| Total Power | 92.95 kW (excluding dust collector) |

| Hammer Disc Brush Size | Φ162 mm |

| Abrasive Belt Size | Φ2400 × 1600 mm |

| Roller Brush Size | Φ350 × 550 mm |

| Feed Speed | 0.5 – 6 m/min (variable frequency) |

| Sanding Belt Linear Speed | Approx. 18 m/s |

| Brush Rotation Speed | 8 – 26 m/s (VFD adjustable) |

| Brush Revolution Speed | 1 – 15 rpm (VFD adjustable) |

| Planetary Brush Heads (Rotation) | 8 pcs |

| Planetary Axis (Revolution) | 1 pc |

| Servo Accuracy – Thickness Adj. | 0.01 mm |

| Servo Accuracy – Brush Comp. | 0.01 mm |

| Grinding Media | Hammerhead + Sanding belt + Roller brushes |

| Dust Extraction Volume | 5000 m³/h |

| Machine Dimensions (L×W×H) | 4800 × 2600 × 2550 mm |

| Machine Weight | Approx. 7 Tons |

Main Equipment Configuration:

| Component | Specs / Brand |

| Hammer Brush Motor | 15 kW (Shiyang) |

| Hammer Oscillation Motor | 1.5 kW reducer motor (Shengbang) |

| Main Sanding Wheel | Φ240 × 1600 mm (Lainasi) |

| Sanding Belt Drive Motor | 22 kW (Shiyang) |

| Brush Rotation Motors (x4) | 4 kW each (Shiyang) |

| Brush Revolution Motor | 2.2 kW (Shengbang) |

| Brush Lift Servo Motor | 750 W (Veichi) |

| Conveyor Width & Belt | 1600 mm (domestic) |

| Conveyor Drive Motor | 4 kW (Leibo) |

| Conveyor Reducer | BKAZ87 (Leibo) |

| Worktable Lift Servo Motor | 1.5 kW (Veichi) |

| Vacuum Suction Fan | 30 kW (Jiuzhou) |

| Vacuum Fan Inverter | 30 kW (Veichi) |

| Inverters (All Units) | Brush: 18.5 kW, Hammer: 15 kW, Conveyor: 4 kW (Veichi) |

| Bearings | High-speed NSK |

| Electrical Control | Low voltage CHINT |

| Control System | PLC + 7" Touch Screen (Veichi) |

️ Installation Requirements:

Space: 7m × 7m level ground

Power Supply: 380V, 50Hz (±10%)

Compressed Air: Clean and stable air source

Included Documentation & Accessories:

2× User Manuals

Mechanical and Electrical Schematics

Consumables List & Spare Part Specs

Certificate of Conformity

Maintenance Toolkit