Main Processing Scope of the Equipment

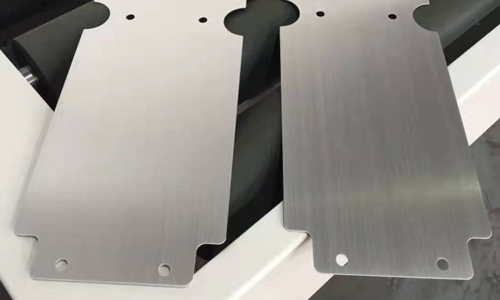

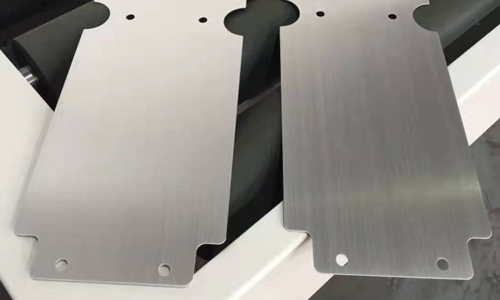

Processing Products: Stainless steel, carbon steel, aluminum sheets, copper plates, various non-ferrous metals, etc.

Introduction to the 1600mm Deburring Machine for Edge Rounding and Surface Finishing of Small Sheet Metal Parts After Laser Cutting and Punching

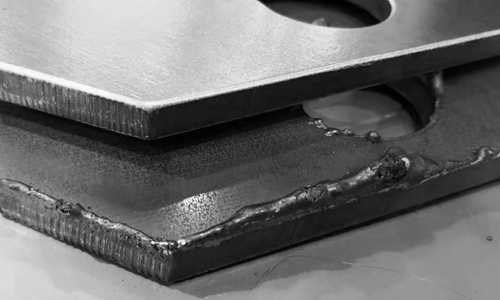

In the modern manufacturing landscape, precision and efficiency are paramount, particularly in industries that deal with small sheet metal parts, such as automotive, aerospace, electronics, and metal fabrication. These industries often rely on laser cutting and punching processes to produce complex and high-precision metal parts. However, these processes, while highly accurate, frequently leave unwanted burrs, sharp edges, and rough surfaces on the workpieces. These imperfections can negatively impact both the functionality and aesthetics of the parts. To address these challenges, deburring and edge rounding machines have become indispensable tools in post-processing operations. Among these, the 1600mm deburring machine stands out as an effective solution for deburring, edge rounding, and surface finishing of laser-cut and punched sheet metal parts.

Main Technical Parameters of the Equipment

| Parameter | Value |

| Processing Width | ≤1580mm |

| Processing Thickness | 0.5 ~ 80mm |

| Minimum Processing Size | 50mm × 50mm (non-perforated parts) |

| Total Machine Power | 42.25KW |

| Disc Brush Size | Φ162mm |

| Sanding Belt Size | Φ2400mm × 1600mm |

| Conveying Speed | 0.5 ~ 6m/min (frequency adjustable) |

| Sanding Belt Speed | Approx. 18m/s |

| Processing Thickness Servo Adjustment Accuracy | 0.01mm |

| Grinding Consumables | Sanding Belt + Disc Brushes |

| Dust Air Flow | 5000m³/h |

| Unit Dimensions | Length 2900mm × Width 2500mm × Height 2400mm |

| Total Weight | Approx. 5T |

Equipment Configuration List

| Item | Specification/Model | Quantity | Function | Brand |

| Main Motor for Disc Brushes | 15KW | 1 | Disc brush rotation | Shiyang |

| Motor for Disc Brush Swinging | 1.5KW reduction motor | 1 | Disc brush horizontal swing | Shiyang |

| Main Sanding Wheel | Φ240mm × 1600mm | 1 | Sanding belt grinding | L |

| Main Sanding Motor | 22KW | 1 | Sanding belt power | Shiyang |

| Rubber Conveyor Belt | Width 1600mm | 1 | Material transportation | Domestic |

| Conveyor Motor | 3KW | 1 | Conveyor power | Leipo |

| Conveyor Gearbox | BKAZ87 | 1 | Conveyor transmission | Leipo |

| Table Lift Servo Motor | 750W | 1 | Adjustment for processing thickness | Weichuang |

| Conveyor Motor Inverter | 3KW | 1 | Speed adjustment for conveyor | Weichuang |

| High-Speed Bearings | - | 1 Set | High-speed rotation | NSK |

| Low-Voltage Electrical Equipment | - | 1 Set | Electrical control | Chint |

| Control System | PLC | 1 Set | Machine control | Weichuang |

| Touchscreen | 7 inch | 1 | Machine control | Weichuang |

Key Features for Deburring and Edge Rounding

Deburring with Wide Belt: Specially designed sanding belt for efficient burr removal from punched and laser-cut parts.

Edge Rounding with Disc Brushes: Ensures even rounding of edges to remove sharp points, achieving a smooth, rounded finish. The disc brush station processes edges and holes for uniform rounding.

Flexible Processing for Small Parts: Suitable for processing small sheet metal parts after laser cutting and punching with a working width of up to 1600mm.

Understanding the Role of a Deburring Machine

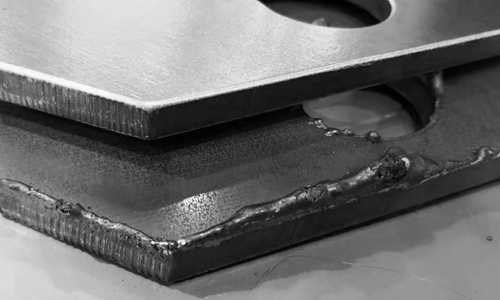

Before delving into the specifics of the 1600mm deburring machine, it is essential to understand the deburring process. Deburring is the process of removing burrs—unwanted protrusions or rough edges—from metal parts. These burrs are typically caused during the manufacturing process, particularly during cutting, punching, or laser cutting operations. Burrs can affect the performance of the part, cause safety concerns (e.g., sharp edges), and hinder further processing or assembly.

Edge rounding, on the other hand, involves softening or rounding the sharp edges of metal parts to achieve a smooth and polished finish. This not only improves the safety and handling of the part but also contributes to its overall aesthetic and functionality. Similarly, surface finishing refers to the process of refining the surface of a metal part to remove imperfections, such as oxide layers, scratches, and marks left by previous manufacturing processes, ensuring the part is ready for its intended application.

While there are various types of deburring machines available in the market, the 1600mm deburring machine offers a unique combination of capabilities designed to handle a range of deburring, edge rounding, and finishing tasks with high precision and efficiency.

Key Features of the 1600mm Deburring Machine

The 1600mm deburring machine is specifically designed to process small sheet metal parts (typically those that are cut or punched via laser, punching, or plasma cutting). The machine combines multiple features to effectively deburr, edge round, and finish these parts in one continuous, automated operation. Below are some of the key features that make this machine particularly suited for high-volume production environments:

1. Wide Processing Range (Up to 1600mm)

The "1600mm" designation refers to the machine's processing width, meaning it is capable of handling metal sheets with a width of up to 1600mm. This makes the machine versatile enough to process a wide range of small sheet metal parts, including those used in automotive panels, electrical enclosures, HVAC systems, and more. The machine can handle parts with varying thicknesses, typically ranging from 0.5mm to 80mm in thickness.

2. Dry Abrasive Belt System

The 1600mm deburring machine utilizes a dry abrasive belt system that ensures efficient burr removal while minimizing dust and waste. The abrasive belts are specially designed to remove large burrs and rough edges left behind after laser cutting, punching, or plasma cutting. These belts can be easily adjusted for different types of abrasives to accommodate various material types, including carbon steel, stainless steel, aluminum, and non-ferrous metals. The dry sanding system reduces the need for liquid coolants or lubricants, leading to a more environmentally friendly operation with less cleanup.

3. Disc Brush for Edge Rounding and Surface Finishing

One of the standout features of the 1600mm deburring machine is the integration of disc brushes. These rotating brushes work in conjunction with the abrasive belts to provide edge rounding and surface finishing. The disc brushes help soften sharp edges, creating a smooth, rounded finish that is free of burrs. The brushes also ensure that the workpiece surface is polished, removing any minor imperfections or oxide layers that may have formed during the cutting process. By adjusting the pressure and speed of the brushes, operators can achieve a consistent and uniform edge rounding across a variety of metal types and thicknesses.

4. High-Speed Operation

The 1600mm deburring machine is designed to operate at high speeds, making it highly efficient for production environments. The machine can process parts at speeds of up to 6 meters per minute. This ensures that even high-volume production runs can be handled efficiently, with minimal downtime. Additionally, the machine features an adjustable speed control system, allowing operators to fine-tune the processing speed based on the specific requirements of the workpiece.

5. Vacuum Conveyor System

To ensure smooth and secure handling of parts during processing, the 1600mm deburring machine is equipped with a vacuum conveyor system. This system uses strong vacuum suction to hold the workpieces firmly in place during processing, preventing any unwanted movement that could affect the accuracy of the deburring or edge rounding operations. The vacuum system can handle workpieces with dimensions as small as 50mm x 50mm (without holes) and ensures consistent part positioning, which is critical for maintaining high-quality finishes.

6. Dust Collection and Environmental Protection

Dust and debris generated during the deburring process can pose both safety and environmental hazards. To mitigate this, the 1600mm deburring machine is equipped with a wet dust collection system. The system uses high-flow fans and a water-based filtration process to capture and filter the dust particles, ensuring a cleaner and safer work environment. The water spray helps capture fine metal particles, and the clean air is then safely discharged into the atmosphere. This closed-loop system ensures that harmful particles are not released into the environment, contributing to sustainable and safe production practices.

7. Precision Adjustment for Processing Thickness

The machine is equipped with servo-driven adjustments that allow for precise control over the processing thickness. This is particularly important when working with varying material thicknesses, as it ensures that each workpiece is processed with the correct amount of abrasive force. The system can adjust the processing thickness with a precision of 0.01mm, ensuring that even the most delicate parts are deburred without affecting their dimensions or tolerances.

8. User-Friendly Control Interface

The 1600mm deburring machine is designed with an intuitive control interface, typically featuring a PLC (Programmable Logic Controller) and touchscreen for easy operation. The operator can monitor the machine's performance, make adjustments, and control various settings such as speed, pressure, and processing thickness. The advanced controls ensure that operators can achieve the desired results with minimal effort, reducing the risk of errors and improving overall efficiency.