200 Ton Bending Force:This machine delivers a bending force of 200 tons, which is ideal for bending thick and heavy sheet metal materials with precision. Whether you're working with steel, aluminum, or other alloys, this press brake can provide the necessary power to shape metal sheets up to 3200mm in length.

3200mm Bending Length:With a bending length of 3200mm, the machine is capable of handling large sheets of metal, making it suitable for a variety of bending applications. It can accommodate a wide range of workpiece sizes, offering flexibility for both small-scale and large-scale production.

CNC Control System:The machine is equipped with an advanced CNC (Computer Numerical Control) system that provides precise control over the bending process. The CNC interface allows for easy programming, real-time monitoring, and adjustment of settings, ensuring high accuracy and repeatability across multiple jobs.

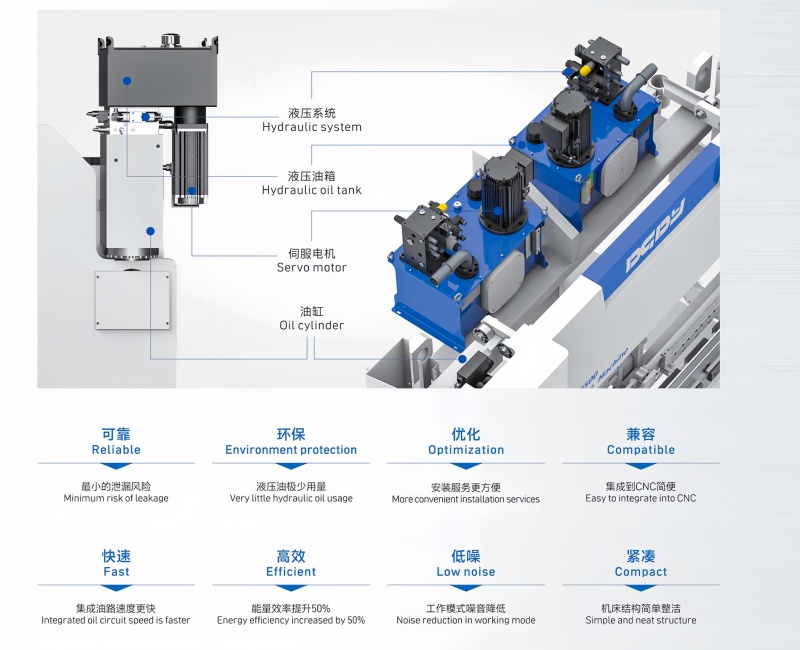

Hydraulic-Electric Hybrid Technology:The hydraulic-electric hybrid system combines the power of hydraulic systems with the precision of electric servo drives. The hydraulic system ensures robust power for heavy-duty tasks, while the electric servo motors provide superior speed and energy efficiency. This hybrid technology offers the best of both worlds—high power with reduced energy consumption.

Energy Efficiency:One of the standout features of this press brake is its energy efficiency. The combination of hydraulic and electric systems ensures optimal power consumption, minimizing waste and reducing operating costs. The servo-electric technology optimizes energy usage by adjusting power output based on the load, leading to significant savings in energy and cost.

Precision and Accuracy:The CNC control system ensures that the machine operates with exceptional precision. It allows for fine adjustments to be made to the bending angle, back gauge position, and stroke length. This ensures that every bend is accurate to within fractions of a millimeter, improving the quality and consistency of the finished product.

Back Gauge System:The CNC-controlled back gauge system allows for precise adjustment of the sheet metal’s position, ensuring repeatability and reducing setup times. The back gauge is highly adjustable, making it easy to accommodate different part sizes and configurations. This system is essential for handling complex or multiple bends in a single operation.

Quick Stroke Adjustment:The machine offers quick stroke adjustments, allowing the operator to easily modify the depth and speed of the ram’s downward movement. This flexibility enables the machine to handle a variety of materials and thicknesses efficiently.

Automatic Ram Positioning:The automatic ram positioning system offers precise control over the ram’s downward stroke, ensuring consistent bending angles. The ram’s position can be adjusted automatically based on the material thickness and the required bend angle, allowing for quicker setup and better accuracy.

High-Speed Operation:With fast approach speeds and quick return speeds, this press brake increases overall cycle time efficiency. This helps to increase productivity in high-volume operations, reducing downtime and improving output.

Safety Features:Safety is a top priority with this machine. It comes equipped with multiple safety features including light curtains, safety shields, and emergency stop buttons. The CNC control system can also monitor the system for any potential faults, helping to prevent accidents and ensuring the safety of the operator.

User-Friendly Interface:The CNC control system features a touchscreen interface that is easy to use and allows for simple programming and operation. Operators can store bending programs, monitor production progress, and make real-time adjustments to the machine. This intuitive interface minimizes the learning curve and increases operator efficiency.

Maintenance-Friendly:The 200T 3200mm CNC Hydraulic-Electric Press Brake is designed with ease of maintenance in mind. Its modular design makes it easier to replace components when necessary, and regular maintenance tasks such as oil changes, filter replacements, and cleaning are straightforward and require minimal downtime.

Environmental Impact:The machine's energy-efficient design not only reduces operational costs but also lowers its carbon footprint. The servo-electric system reduces energy consumption, making it a more environmentally friendly choice compared to traditional hydraulic systems.

Automotive Manufacturing:The 200T 3200mm CNC Hydraulic-Electric Press Brake is ideal for the automotive industry, where high precision is required for components such as body panels, chassis, and structural parts.

Aerospace:Aerospace applications demand extremely high precision and reliability. This machine’s advanced CNC control and hybrid technology make it suitable for bending lightweight alloys and sheet metal used in the aerospace sector.

Construction:For the construction industry, the press brake is used to shape metal sheets and profiles for structural components, supporting the creation of buildings, bridges, and other infrastructure projects.

General Metal Fabrication:This press brake can be used in a variety of fabrication processes, from producing custom metal parts to manufacturing industrial machinery, furniture, and other metal goods.

Sheet Metal Working:The 200T 3200mm machine excels in general sheet metal working, offering the precision needed to bend sheets of various thicknesses and types, including steel, aluminum, and stainless steel.