Industrial Nitrogen Generators for Laser Welding

ZHN-L Series Laser Welding Nitrogen Generators

(Models: ZHN-01L / ZHN-02L / ZHN-03L)

Overview

The ZHN-L Series Laser Welding Nitrogen Generators are advanced, high-performance gas generation systems designed to meet the demanding needs of modern laser welding operations. Engineered with precision and manufactured to the highest quality standards, these machines deliver a reliable and continuous supply of high-purity nitrogen gas directly on-site.

By eliminating the dependency on bottled nitrogen, the ZHN-L series significantly reduces operational costs, simplifies logistics, and improves overall welding efficiency. With cutting-edge control systems, integrated purification technology, and a compact, user-friendly design, these nitrogen generators are the ideal solution for manufacturers, workshops, and industrial facilities seeking superior welding performance and productivity.

Key Features

1. PLC Control System

Each ZHN-L nitrogen generator is equipped with a modern Programmable Logic Controller (PLC), ensuring intelligent, stable, and automated operation.

Continuous monitoring of system parameters

Automatic fault detection and alarm functions

Easy control via the touch interface

Optimized nitrogen generation for efficiency and performance

This intelligent control ensures that the nitrogen purity and flow remain consistent during the entire welding process, guaranteeing repeatable, high-quality results.

2. Built-in Refrigerated Air Dryer

Moisture in compressed air can negatively affect both the nitrogen purity and the welding quality. The ZHN-L series integrates a high-efficiency refrigerated air dryer, which:

Removes moisture from the incoming compressed air

Prevents oxidation and contamination

Extends the service life of filters and nitrogen separation modules

This built-in feature ensures that the nitrogen supply is always dry, clean, and stable.

3. Triple Filtration System

For applications that demand extremely pure nitrogen (up to 99.999%), the ZHN-L nitrogen generators include a three-stage filtration process:

Pre-filter: Removes large particles and oil mist

Fine filter: Eliminates small particulate matter and residual oil

High-efficiency filter: Ensures ultra-clean, high-purity nitrogen output

The triple filtration not only improves gas quality but also protects downstream equipment and laser welding heads from damage.

4. Automatic Drainage

The system features automatic condensate drainage, minimizing maintenance needs and preventing moisture buildup.

This reduces downtime, lowers labor costs, and maintains consistent nitrogen purity over extended periods.

5. Direct Connection to Air Compressors

The ZHN-L series is designed to integrate seamlessly into existing workshop setups. It can be connected directly to an air compressor, with the gas ready for immediate use.

No additional storage tanks or complicated pipelines are necessary, making installation fast and cost-effective.

6. 7-Inch Multilingual Touchscreen Interface

User interaction is made simple with a 7-inch industrial-grade touchscreen, supporting multiple languages for global operation.

Clear display of operating status

Easy adjustment of parameters

Quick troubleshooting guidance

Suitable for operators of different skill levels

Applications in Laser Welding

Nitrogen plays a crucial role in laser welding by preventing oxidation, improving bead appearance, and reducing porosity in weld joints. The ZHN-L series provides:

Stable Gas Flow – Essential for consistent welding results

High Purity – Reduces discoloration and oxidation of metals

Versatility – Suitable for welding stainless steel, aluminum alloys, titanium, and more

These generators are ideal for use with:

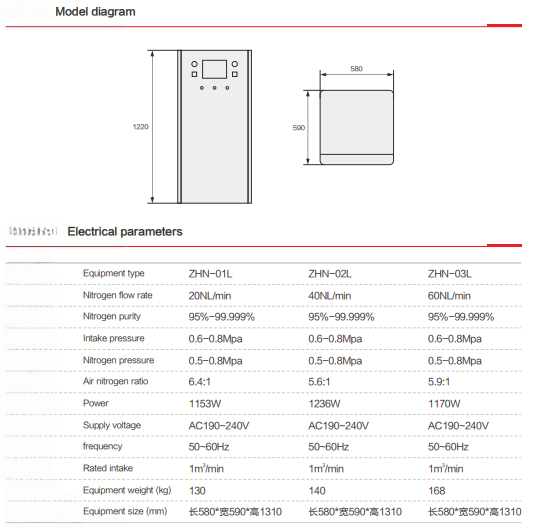

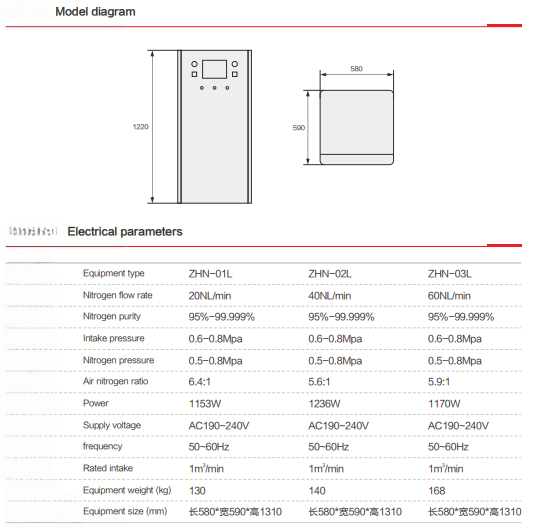

Model Specifications

| Model | Nitrogen Flow Rate | Nitrogen Purity | Intake Pressure | Nitrogen Pressure | Air:Nitrogen Ratio | Power | Supply Voltage | Frequency | Rated Intake | Weight (kg) | Dimensions (mm) |

| ZHN-01L | 20 NL/min | 95% – 99.999% | 0.6 – 0.8 MPa | 0.5 – 0.8 MPa | 6.4 : 1 | 153 W | AC 190–240 V | 50–60 Hz | 3.1 m³/min | 130 | 580×590×1310 |

| ZHN-02L | 40 NL/min | 95% – 99.999% | 0.6 – 0.8 MPa | 0.5 – 0.8 MPa | 5.6 : 1 | 236 W | AC 190–240 V | 50–60 Hz | 3.1 m³/min | 140 | 580×590×1310 |

| ZHN-03L | 60 NL/min | 95% – 99.999% | 0.6 – 0.8 MPa | 0.5 – 0.8 MPa | 5.9 : 1 | 170 W | AC 190–240 V | 50–60 Hz | 3.1 m³/min | 168 | 580×590×1310 |

Advantages over Traditional Nitrogen Supply

On-Demand Generation – No waiting for deliveries, no risk of running out of gas during production.

Cost Savings – Eliminates recurring costs of cylinder rental, refills, and transportation.

Consistent Purity – Produces nitrogen with a stable purity level tailored to your welding needs.

Environmental Benefits – Reduces carbon emissions from gas transportation.

Compact Footprint – Space-saving design suitable for small workshops and large factories alike.

Why Choose the ZHN-L Series for Laser Welding?

Precision Engineering: Designed specifically for laser welding applications, ensuring optimal gas purity and pressure stability.

Durability: Built with industrial-grade materials for long-term, continuous operation.

Ease of Use: Simple installation, intuitive controls, and minimal maintenance requirements.

Flexibility: Available in three models to suit different production scales – from small workshops to high-volume manufacturing.

Maintenance & Service

The ZHN-L series is designed with minimal maintenance in mind.

Filters can be replaced quickly without special tools

Automatic drainage reduces manual intervention

Long-life components reduce downtime and maintenance costs

Our global service network ensures that technical support, spare parts, and maintenance guidance are available wherever you operate.

Conclusion

The ZHN-L Series Laser Welding Nitrogen Generators combine advanced gas separation technology, intelligent controls, and robust construction to deliver a continuous, high-purity nitrogen supply for demanding welding applications.

Whether you are a small fabrication shop or a large-scale manufacturer, the ZHN-L series offers the reliability, efficiency, and performance needed to achieve top-quality welds while reducing operational costs.

By investing in a ZHN-L nitrogen generator, you are securing a competitive advantage in both productivity and product quality.