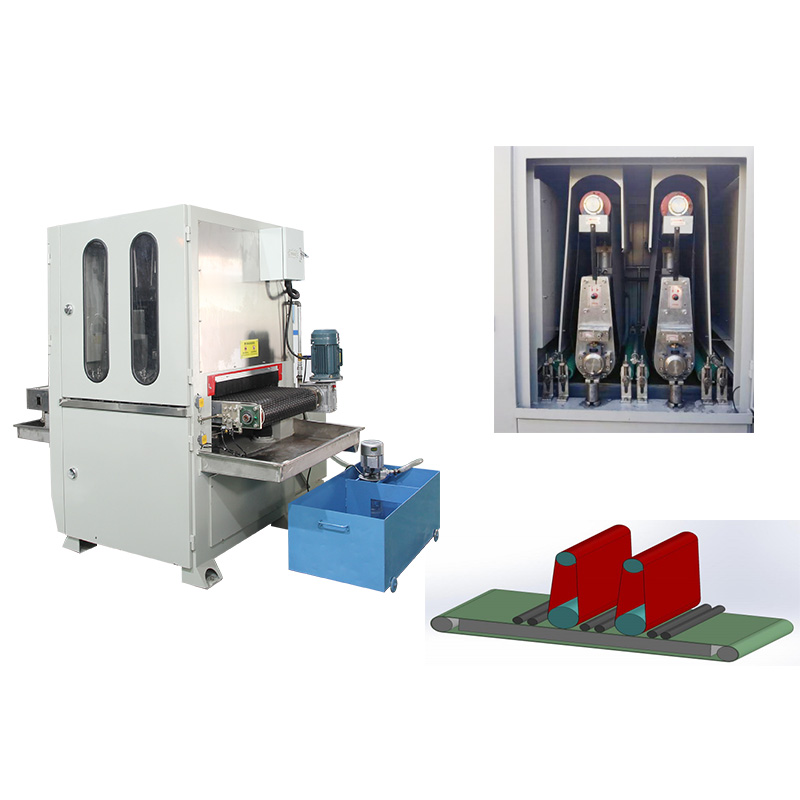

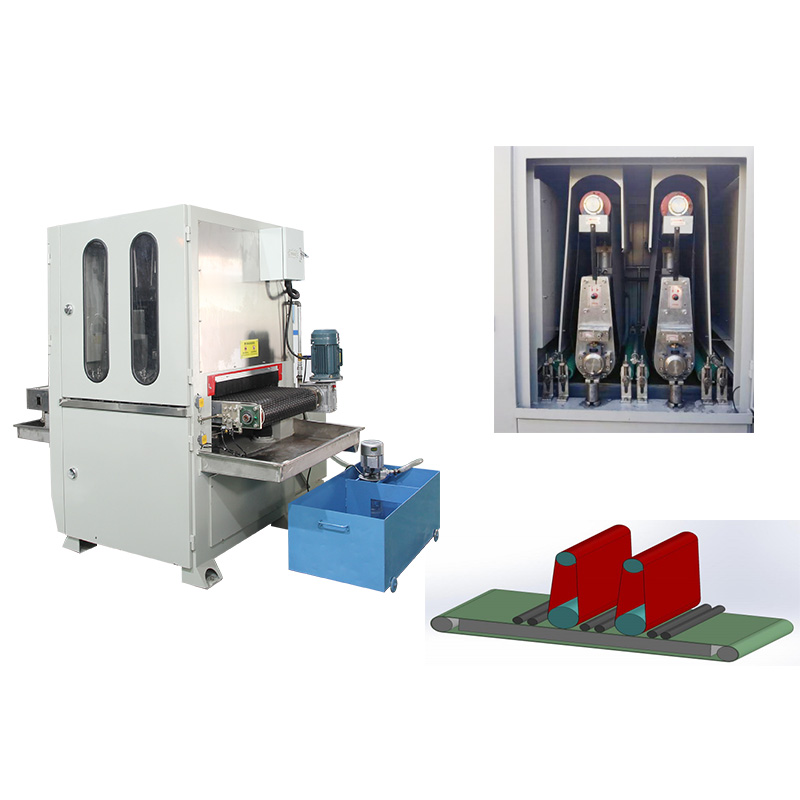

24.8-inch (630mm) Wide Belt Sander for Metal Finishing

The 24.8-inch (630mm) Wide Belt Sander is an advanced surface finishing machine designed for industrial applications in metalworking. It is capable of performing a range of tasks including sanding, deburring, edge rounding, calibrating, and finishing. These versatile machines are typically used in industries like automotive manufacturing, sheet metal processing, aerospace, and general metal fabrication, ensuring high-quality results across a variety of metal types.

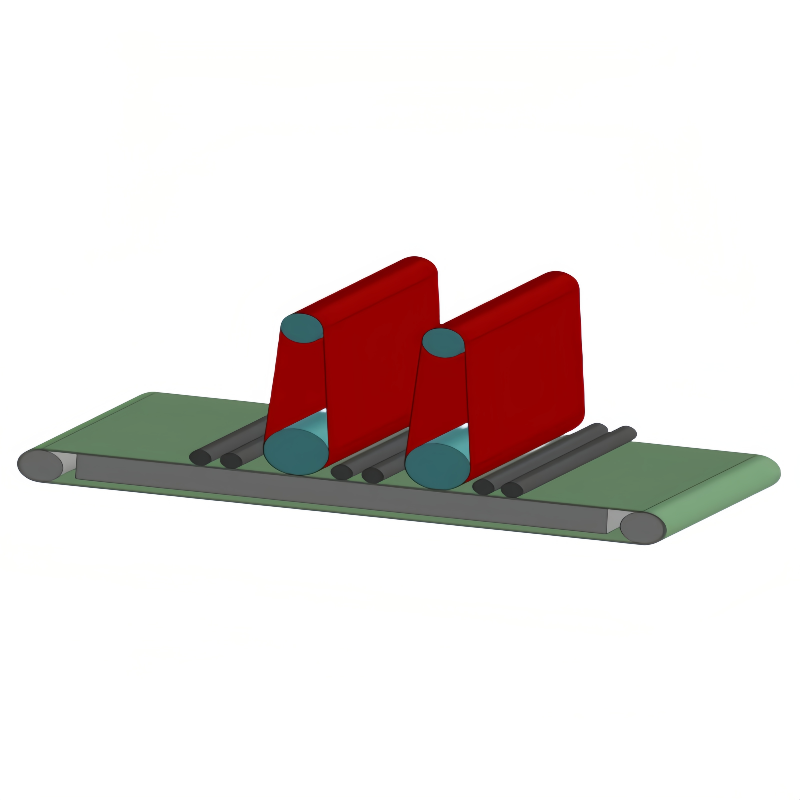

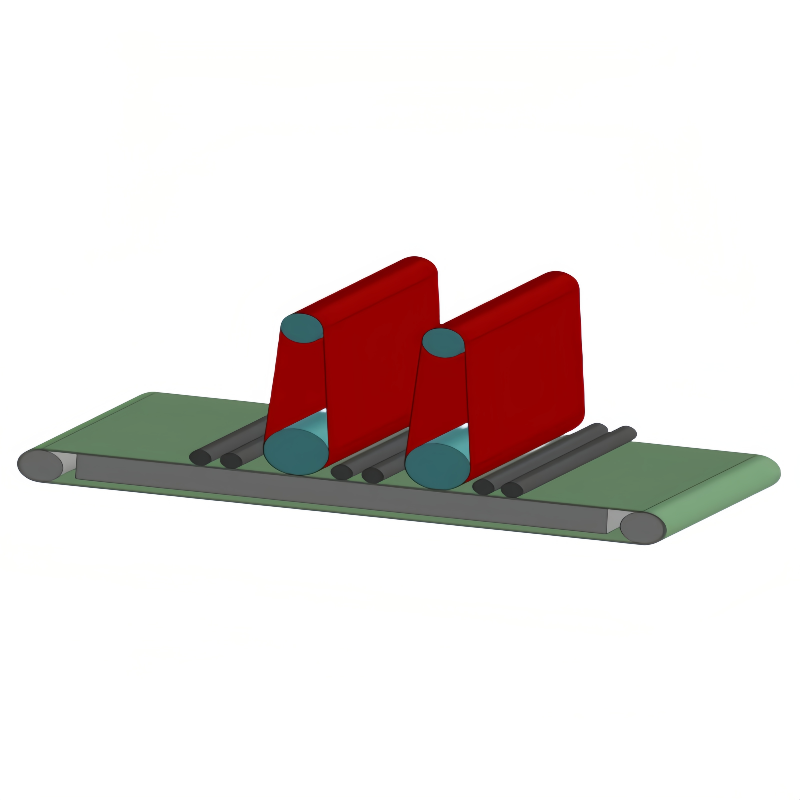

The machine is equipped with 2 sanding belts. This configuration enables optimal results in metal finishing processes. Available in different models, each with unique configurations, the machine can adapt to various sanding and finishing needs depending on the complexity of the application.

Key Features and Capabilities

High Working Width:

With a maximum working width of 630mm, the machine is suitable for processing medium to large-sized metal parts, ensuring high throughput and efficiency.

Multiple Sanding Stages:

The machine is equipped with three sanding belts and optional polishing wheels. Different configurations of these belts and polishing units provide flexibility to handle tasks like deburring, sanding, and finishing, depending on the material and required finish.

Precision Power:

The sanding belts are powered by high-capacity motors that ensure optimal belt performance, while the polishing wheel provides additional finishing capabilities to achieve smooth surfaces.

Flexible Adjustable Settings:

The sanding unit's settings can be adjusted according to the specific needs of the material being processed, including belt speed, height adjustment, and oscillation. This ensures that the machine can handle various workpieces effectively.

Vacuum and Dust Extraction:

Integrated vacuum systems ensure a cleaner working environment by effectively extracting dust and debris during the sanding process, contributing to both safety and efficiency.

Technical Specifications

| Parameter | Unit | R630 | RR630 | RP630 | RRR630 | RRP630 |

| Maximum Working Width | mm | 630 | 630 | 630 | 630 | 630 |

| Maximum Working Height | mm | 60 | 60 | 60 | 60 | 60 |

| Minimum Working Length | mm | 220 | 220 | 220 | 220 | 220 |

| 1st Sanding Belt Power | kW | 15 | 15 | 15 | 15 | 15 |

| 2nd Sanding Belt Power | kW | - | 11 | - | 11 | 11 |

| 3rd Sanding Belt Power | kW | - | - | - | 11 | - |

| Polishing Wheel Power | kW | - | - | 11 | - | 11 |

| Rotary Motor Power | kW | - | - | - | - | - |

| Feeding Motor Power | kW | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 |

| Lifting Motor Power | kW | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 |

| Oscillation Motor Power | kW | - | - | 1.5 | - | 1.5 |

| Vacuum Motor Power | kW | - | - | - | - | - |

| Machine Dimensions | m | 1.8×1.9×2 | 2.1×1.9×2 | 2.1×1.9×2 | 2.4×1.9×2 | 2.4×1.9×2 |

| Machine Weight | kg | 1400 | 1600 | 1600 | 1800 | 1800 |

| Sanding Belt Size | mm | 1900×630 | 1900×630 | 1900×630 | 1900×630 | 1900×630 |

Machine Model Overview

R630 / RR630 / RP630 / RRR630 / RRP630

R630: Ideal for applications requiring high sanding power and efficiency with basic configurations. This model provides significant sanding capacity and smooth surface finishes for medium-sized workpieces.

RR630 / RP630: These models come with enhanced motor power, including additional power for the second sanding belt. The RR630 and RP630 configurations allow for more specific finishing and deburring capabilities with multiple sanding belts, providing a more polished finish on metal surfaces.

RRR630 / RRP630: These are the top-tier models in the range, designed with high-end features, including multiple sanding belts, polishing wheels, and oscillation motors for additional finishing stages. The RRR630 and RRP630 can handle complex deburring and surface treatment tasks with precision.

Applications

The 24.8-inch (630mm) Wide Belt Sanders are commonly used in a variety of industries for processing different types of metal, including:

Automotive Manufacturing: Surface preparation for parts like body panels, chassis components, and engine parts.

Metal Fabrication: Finishing of cut or welded parts from steel, aluminum, and other metals, ensuring a smooth and consistent surface.

Aerospace: Precision sanding and deburring of metal parts used in aircraft manufacturing.

Heavy Equipment Manufacturing: Calibration, deburring, and surface finishing of large metal components.

Construction: Sanding and finishing of metal profiles, pipes, and steel plates used in building structures.

Key Advantages

High Productivity: The machine’s multiple sanding belts and powerful motors allow for continuous, high-speed operation, maximizing throughput.

Versatility: With different configurations and adjustable settings, the wide belt sander can be tailored to meet the specific needs of different industries and materials.

Precision Finishing: The ability to adjust belt tension, feed speed, and motor power ensures precise control over the sanding process, delivering consistent surface quality.

Dust Extraction and Safety: Integrated vacuum systems reduce airborne debris and dust, ensuring a cleaner and safer working environment.

Long-lasting Performance: Designed for heavy-duty use, these machines are built to handle demanding workloads while ensuring long-term reliability.