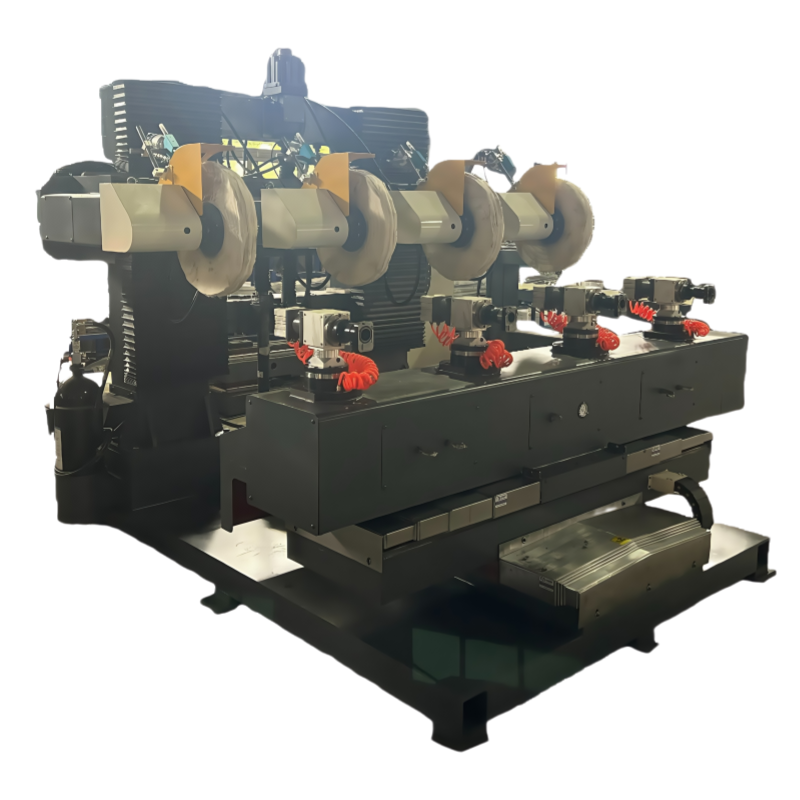

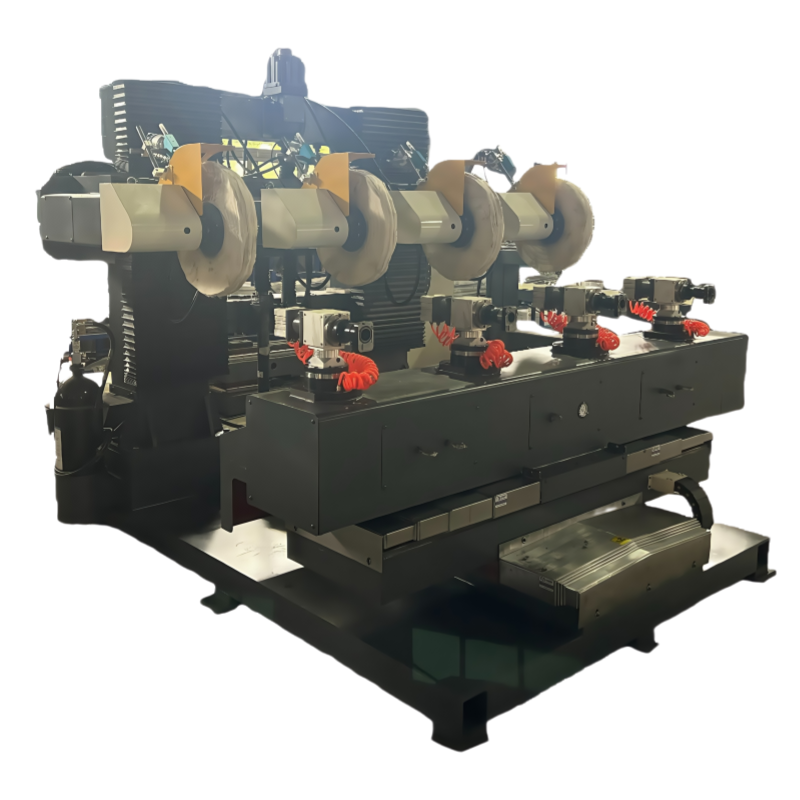

CNC Polishing Machine for Polishing and Brightening Door Handles and Door Knobs

The CNC Polishing Machine for Polishing and Brightening Door Handles and Door Knobs is a state-of-the-art automated solution designed to meet the complex demands of polishing parts with intricate geometries. Featuring five programmable interpolating CNC axes, this machine is built to deliver high-quality finishes, offering precise control over each part’s polishing process. Specifically engineered for the polishing and brightening of door handles, door knobs, and other similar components, this machine guarantees consistent, high-performance results, whether for small-scale or mass production.

This advanced machine is ideal for the production of door hardware and fittings that require a flawless surface finish, including brass, stainless steel, and aluminum door handles, knobs, and levers. By providing automated polishing, the machine reduces labor costs and enhances production efficiency, making it a valuable tool for manufacturers aiming for both superior quality and high-volume output.

Key Features and Benefits

Five Programmable Interpolating CNC Axes

The heart of the machine is its five programmable interpolating CNC axes, providing high precision and flexibility in the polishing process. This enables the machine to adjust to different shapes, sizes, and geometries of parts, from door knobs to handles with complex curves, ensuring uniform polishing on all surfaces. Whether the part is a simple cylindrical knob or a more intricate, multi-faceted handle, the machine guarantees accurate and consistent polishing.

The CNC axes allow for detailed adjustments, providing control over every aspect of the polishing process. This results in a uniform finish and a flawless final product, which is essential for door hardware that needs to look aesthetically perfect while maintaining structural integrity.

Automated Polishing for Complex Parts

This machine is specifically designed for automated polishing of parts with complex shapes. Traditional methods of polishing often require significant manual labor and expertise to achieve the desired finish, especially on intricate surfaces. The CNC machine automates the entire polishing process, which not only reduces labor costs but also minimizes human error, ensuring a consistent and repeatable high-quality finish for every part.

Parts such as door handles, knobs, and fittings, which are often designed with complicated angles, intricate designs, and fine contours, are effortlessly polished to perfection using the advanced control of the five axes.

Simultaneous Processing of Four Parts

One of the most advantageous features of this CNC polishing machine is its ability to process four parts simultaneously in each cycle. This increases the machine’s throughput, making it highly efficient for mass production of door handles and door knobs. By polishing multiple parts at once, manufacturers can significantly reduce production time while maintaining the same level of high-quality output. This simultaneous processing feature is particularly valuable for manufacturers looking to scale up their production without compromising quality.

Versatile Applications

This machine is designed for a wide range of polishing applications, including but not limited to:

Deburring: Removing burrs and sharp edges from parts that result from casting, machining, or other manufacturing processes.

Grinding: Smoothing rough surfaces to prepare parts for further finishing or polishing.

Polishing: Achieving a high-gloss, mirror-like finish, ideal for aesthetic parts like door handles and knobs that require a refined appearance.

Satin Finishing: Producing a brushed, matte effect that is often preferred for more industrial or contemporary designs of bathroom fittings, shower handles, and door accessories.

Each of these applications can be integrated into the polishing cycle, providing flexibility in production and finish types, whether you need a high-gloss shine or a satin, brushed look.

Teach-In Programming for Easy Setup

The teach-in programming feature makes setting up the machine simple and intuitive. Operators can teach the machine how to perform specific polishing actions for various parts. Once the polishing parameters are set, the machine stores these settings for future use, allowing for easy and repeatable production runs. This system eliminates the need for complicated programming or advanced technical skills, enabling quick and easy adjustments for different parts or finishes.

The teach-in programming feature ensures that the machine can adapt to a variety of different products, whether they are door handles, knobs, or bathroom fittings, making it a versatile tool for manufacturers with varied production needs.

Guaranteed Homogeneous Polishing

With the CNC polishing machine, homogeneous polishing is guaranteed, even for the most complex geometries. Whether polishing a brass door handle or a stainless steel knob, the machine applies the same polishing force evenly across all surfaces, eliminating imperfections or inconsistencies that often occur with manual polishing methods. This ensures that every part receives the same treatment, delivering a uniform finish across all components.

Additionally, the machine ensures no deformation of the part during the polishing process, which is critical for maintaining the integrity and aesthetic quality of door hardware. The result is a high-quality, smooth, and durable surface finish on every piece.

Automatic Spraying Gun Adjustment

The machine is equipped with automatic spraying gun adjustment, which optimizes the application of polishing compounds and sprays. This feature adjusts the position of the spraying guns based on the diameter of the polishing mops, ensuring that polishing compound is applied evenly across the surface of the part. The result is an efficient polishing process with minimal waste, which is both cost-effective and environmentally friendly.

Energy Efficient with Low Operating Costs

Designed with energy efficiency in mind, this machine minimizes operating costs by reducing the amount of polishing compound and mops required for each cycle. With its high automation and minimal human intervention, the machine not only reduces labor costs but also consumes less energy compared to traditional polishing methods. This makes the machine an ideal choice for companies seeking to reduce their overall production expenses while maintaining a high level of performance.

Flexible Production with Quick Setup

The CNC polishing machine is highly flexible, capable of processing various parts without lengthy downtime between different models. The machine allows for quick setup and easy changeover of parts. Operators can change the grippers and polishing mops quickly, allowing for short production runs or multiple different parts in a single production cycle. This makes it an excellent option for manufacturers who need to produce a variety of products, including door handles, door knobs, and other hardware components, without significant production delays.

Applications and Industries

Door Hardware and AccessoriesThe machine is perfect for polishing and brightening a wide variety of door hardware components, including door handles, door knobs, and levers. Since these parts often require both functional durability and aesthetic appeal, the machine ensures that they meet high standards for both appearance and performance. It works seamlessly with a variety of materials, including brass, stainless steel, and aluminum, which are commonly used in door hardware production.

Bathroom FittingsIn addition to door hardware, this machine is also ideal for polishing and finishing bathroom fittings, such as faucet handles, shower heads, and other bathroom accessories. These items often require high-quality polishing for both aesthetic appeal and durability, making this CNC machine a versatile solution for manufacturers in the bathroom fixture industry.

Sanitary Ware and Other Metal ComponentsBeyond door hardware and bathroom fittings, this machine can also polish and finish other metal components used in various industries, including furniture hardware, automotive parts, and aerospace components. Its ability to handle different types of metal finishes, including polished, satin, and brushed, makes it a valuable asset for manufacturers in a variety of industries.

Conclusion

The CNC Polishing Machine for Polishing and Brightening Door Handles and Door Knobs offers a highly efficient and cost-effective solution for the automated polishing of complex parts. Featuring five programmable CNC axes, simultaneous processing of four parts, and teach-in programming, this machine is designed to optimize production efficiency while ensuring consistent, high-quality finishes. Whether for polishing brass, stainless steel, or aluminum components, it guarantees uniform polishing, homogeneous finishes, and low operating costs.

This CNC polishing machine is the ideal choice for manufacturers looking to improve production speed, reduce labor costs, and maintain the highest standards of surface finish quality for products such as door handles, door knobs, and bathroom fittings. Its flexibility, high production capacity, and ease of use make it an indispensable tool for a wide range of industries, offering an excellent return on investment and long-term production benefits.