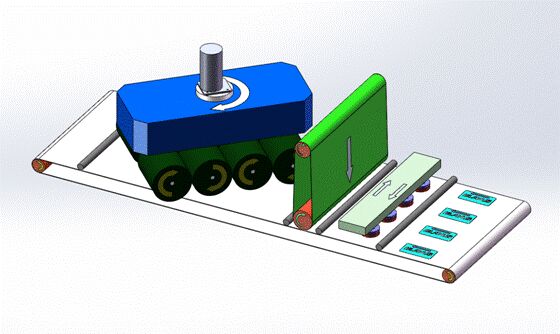

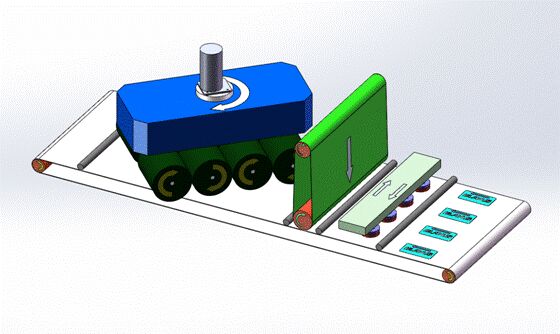

The grinding and deburring machine you described offers several key advantages and applications, specifically suited for mechanical slag removal and edge rounding on plate material.

Key Features:

Heavy-duty Conveyor Belt: Designed to handle heavy workpieces, the machine is equipped with a robust, long-life conveyor belt, ensuring stability and reliability during operation.

Mechanical Slag Removal: This machine excels at removing slag from plasma, oxy-fuel, or laser-cut plates. The mechanical slag removal helps reduce the need for expensive grinding processes.

Edge Rounding: The machine is capable of performing high-quality edge rounding, up to a 2mm radius, ensuring smooth, burr-free edges on the material.

Processing Plate Material: It is specifically designed for processing plate material, making it suitable for various industries requiring high-quality surface finishes and consistent results.

Applications:

Materials: Suitable for processing stainless steel, steel, aluminum, and non-ferrous metals.

Slag Removal: Ideal for plasma and oxy-fuel cut parts.

Edge Rounding: Perfect for providing precise edge rounding on various thicknesses of material.

Technical parameters of the equipment :

| Parameter | Specification |

| Maximum Processing Width | ≤780mm |

| Processing Thickness | 0.5–80mm |

| Minimum Part Size | 50mm × 50mm |

| Total Power | 22KW |

| Sanding Roller Brush Size | Φ300mm × 300mm |

| Conveyor Speed | 0.5–6m/min (Variable Frequency Adjustable) |

| Roller Brush Speed | 8–26m/s (Variable Frequency Adjustable) |

| Planetary Rotation Speed | 1–15r/min (Variable Frequency Adjustable) |

| Planetary Rotation Axle Heads | 1 |

| Planetary Self-Rotation Axle Heads | 4 |

| Material Thickness Servo Adjustment Precision | 0.01mm |

| Grinding Consumables | Roller Brush+Slag Removal |

| Dust Extraction Air Volume | 3000m³/h |

| Dimensions (L × W × H) | 2350mm × 1750mm × 2150mm |

| Weight | Approx. 1.6T |

The MSP-D800 is an advanced universal grinding and deburring machine designed for slag removal, deburring, and edge rounding of oxy-fuel and plasma-cut plates, as well as steel and stainless steel parts. This machine integrates multiple processing steps into one efficient operation, improving productivity and ensuring high-quality results.

Key Features:

Heavy-Duty Conveyor Belt:

The robust conveyor belt is designed for handling heavy workpieces, ensuring consistent movement and stability during processing, even with large, heavy plates.

Mechanical Slag Removal:

Cool Grinding Technology:

By performing the slag removal primarily mechanically, the system avoids heat input into the workpiece—this is referred to as "cool grinding". This feature helps prevent warping or distortion that may occur due to heat buildup during traditional grinding.

Cool grinding also contributes to a longer tool life and cost savings as there is less wear and tear on abrasive materials.

Multi-Step Process in One Operation:

Slag Removal: Efficient removal of slag from plasma and oxy-fuel cut plates.

Deburring: Elimination of burrs from the material edges.

Edge Rounding: Achieves smooth edges with a radius of up to 2mm, ensuring clean and precise results for further handling or finishing.

Versatility in Material Processing:

The machine can process a variety of materials, including steel, stainless steel, and non-ferrous metals, making it suitable for different industrial applications.

Benefits:

Cost Efficiency: The integration of mechanical slag removal and cool grinding significantly reduces operational costs by extending the lifespan of grinding tools and decreasing the need for high-cost consumables.

Improved Workpiece Quality:

Edge rounding ensures that edges are smooth and safe, making the parts easier to handle and prepare for further processes like welding or coating.

Cool grinding ensures that parts are not subjected to thermal distortion, preserving the integrity of the material.

Increased Productivity: The MSP-D800 combines multiple steps in one machine, reducing the need for separate equipment and improving overall throughput.

Low Maintenance Costs: With the mechanical slag removal being the primary method for slag detachment, there is less wear on the grinding tools, reducing maintenance and replacement costs.

Space Efficiency: The robust yet compact design allows for efficient use of space in industrial settings.

Applications:

Oxy-fuel and Plasma-Cut Plates: The machine is perfect for slag removal from plates cut with oxy-fuel or plasma processes.

Steel and Stainless Steel: Ideal for processing steel, stainless steel, and non-ferrous materials.

Edge Rounding & Deburring: Perfect for achieving precise edge finishes and smooth, burr-free surfaces on small or large parts.

Ideal for Industries:

Metal Fabrication: The machine is well-suited for sheet metal processing, improving quality and efficiency in metalworking industries.

Automotive: For edge rounding and deburring of components that will undergo further manufacturing steps such as welding or coating.

Aerospace: Precision finishing of critical components requiring smooth edges and burr-free surfaces.

The MSP-D800 is a versatile, efficient, and durable machine designed for slag removal, deburring, and edge rounding. Here’s a detailed overview of its key features and advantages:

Key Features:

Three Processes in One Pass:

The MSP-D800 combines slag removal, deburring, and edge rounding in a single throughfeed pass, significantly reducing processing time and improving overall productivity.

High-Quality Construction:

Mechanical Slag Removal:

The power pins used for mechanical slag removal ensure that up to 90% of the slag is removed efficiently, significantly extending the tool's lifespan and reducing grinding costs. This process avoids unnecessary wear on grinding tools, making it more cost-effective.

Soft Contact Roller for Warped Parts:

Precise Edge Rounding:

With two rotary heads, the machine provides a perfectly even edge rounding of up to 2mm radius, ensuring smooth, burr-free edges on the processed parts.

Versatility in Material Processing:

Compact and Space-Saving Design:

Serrated Infeed Pressure Rollers:

Ergonomic and Intuitive Controls:

Flexible Operation:

The individual operation of each head provides optimum flexibility, allowing the machine to be tailored for various applications. This flexibility makes the machine adaptable to different part sizes, materials, and processes.

Easy Maintenance and Accessibility:

The optimal accessibility of the machine allows for easy tool changes, cleaning, and maintenance, reducing downtime and improving overall efficiency.

Summary of Advantages:

Time-Saving: Combining slag removal, deburring, and edge rounding in one throughfeed pass streamlines operations and saves valuable processing time.

Durability: Robust construction ensures a long machine life, even under heavy-duty use.

Cost-Effective: The mechanical slag removal process significantly reduces grinding costs and extends tool life.

Precision: The large contact roller and rotary heads deliver consistent results on warped parts and provide even edge rounding.

Versatility: Capable of processing a wide range of materials, including mild steel and stainless steel, for various industrial applications.

Space-Efficient: Compact design makes it ideal for use in factories with limited floor space.

User-Friendly: Intuitive controls and easy-to-access components enhance usability and reduce maintenance effort.

Ideal Applications:

Metal Fabrication: Excellent for deburring and edge rounding metal parts with high precision.

Steel and Stainless Steel Processing: Efficiently handles both mild and stainless steel materials.

Automotive and Aerospace: Perfect for preparing parts for welding or coating processes.

General Manufacturing: Suitable for any application requiring fast and efficient slag removal, deburring, and edge rounding.