Handheld Laser Welding—Stainless Steel Sink Welding

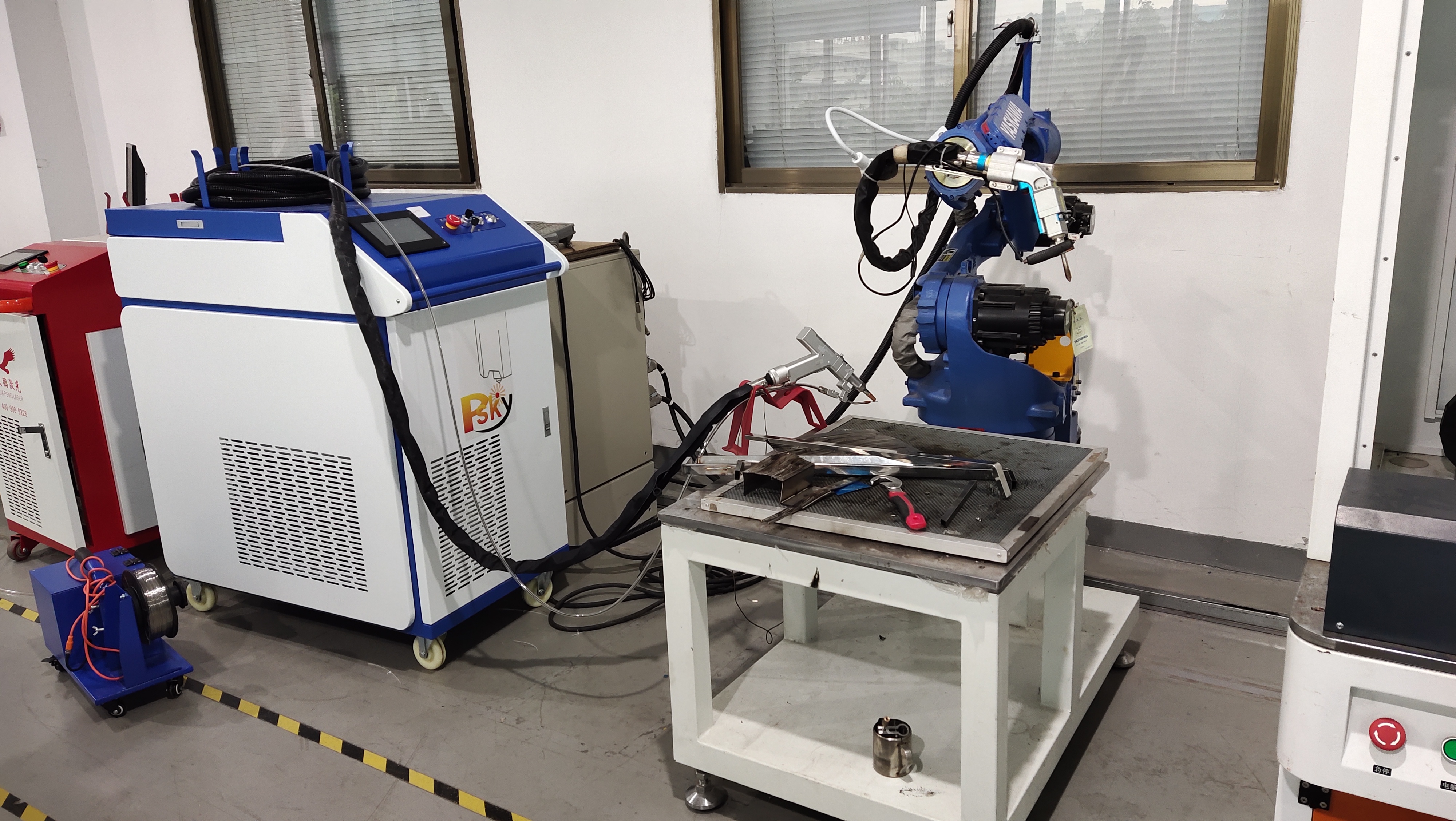

Many users will have questions about which welding method is safer and more reliable for stainless steel sinks. Today, I will introduce the welding method that is more suitable for stainless steel sinks - hand-held laser welding.

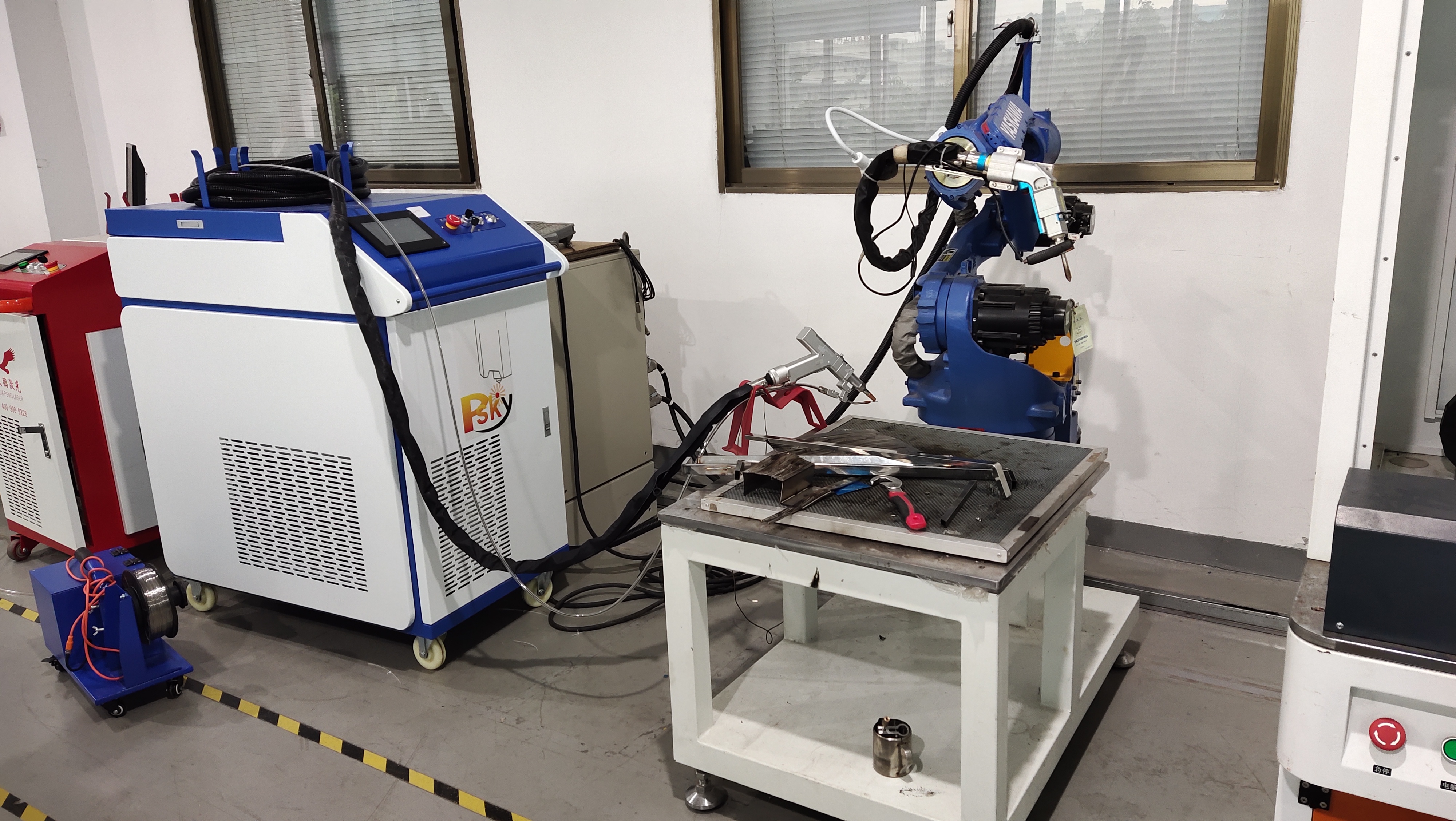

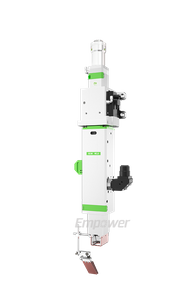

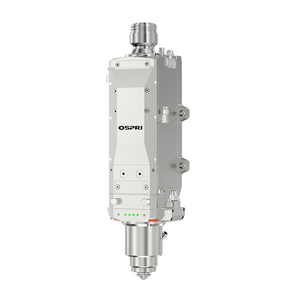

The hand-held laser welding machine for stainless steel sinks and washbasins can use a swing welding head, the spot is adjustable, the welding head adopts motor-driven X, Y-axis vibration lenses, and has a variety of swing modes, and swing welding allows the workpiece to have irregular welding, larger gaps, etc. The machining parameters can significantly improve the welding quality. The protective lens adopts a drawer structure, which is easy to replace. The welding of stainless steel sinks and washbasins is more convenient and fast, and it is widely used in kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrails, power distribution boxes, stainless steel households, etc.

Hand-held laser welding can weld most stainless steels within 6mm, and the use time can be normally 8 hours to 10 hours. It is characterized by fast speed, high efficiency, mostly thin plates, mainly because of the advantages of welding thin plates, the welding speed is faster, which greatly improves the welding efficiency, and at the same time, it can achieve beautiful welds, no scars, no discoloration, and no need for subsequent grinding. , Widely used in kitchen and bathroom industry, home appliance industry, advertising industry, mold industry, stainless steel product industry, stainless steel engineering industry, door and window industry, handicraft industry, household products industry, furniture industry, auto parts industry, etc.