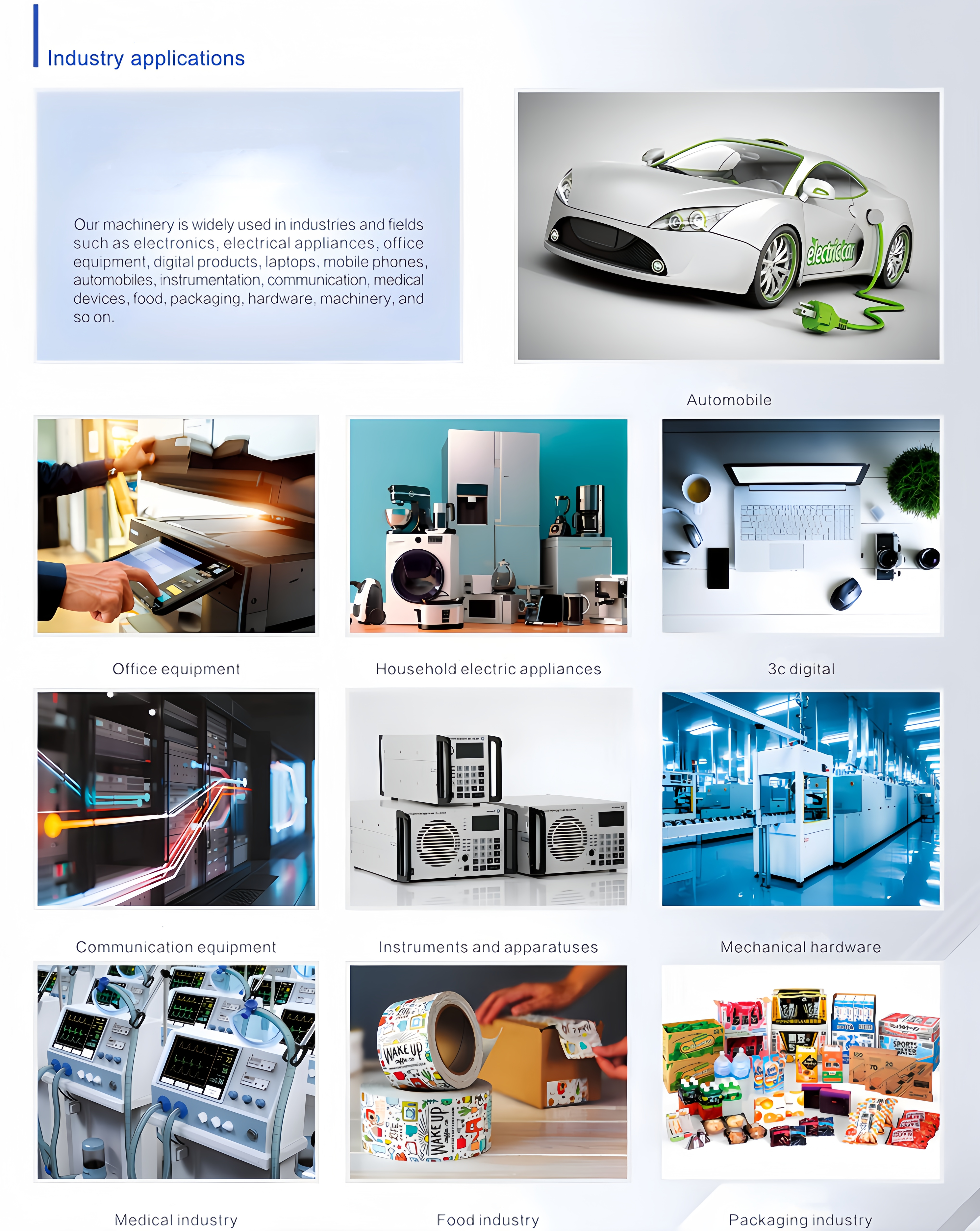

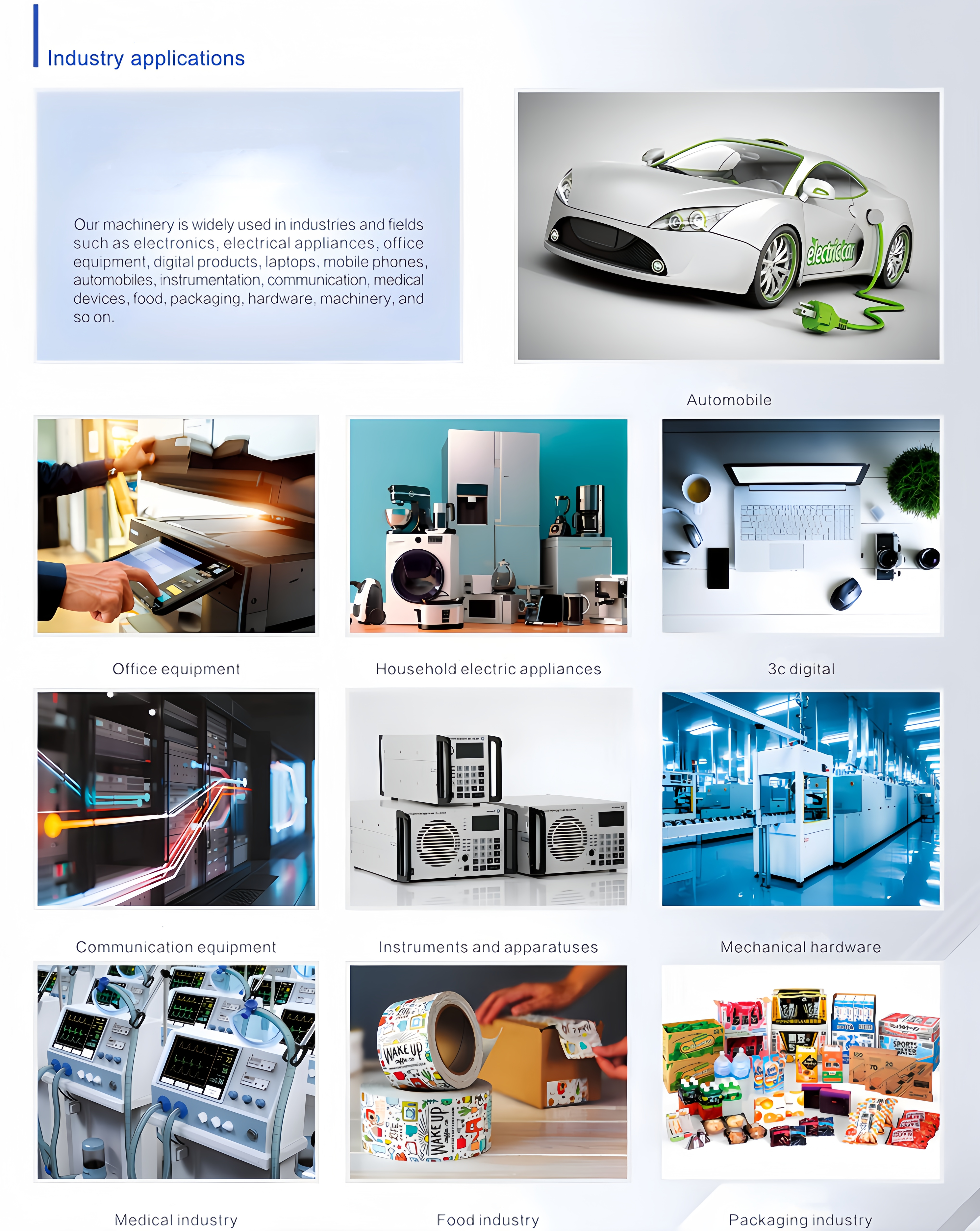

The JG-3501600/5002000 High-Precision Die-Cutting Machine is a specialized piece of equipment designed for precision die-cutting applications, particularly suitable for thin films, adhesive materials, electronic components, and other delicate materials. It excels in the perfect cutting of non-metallic materials such as 3M, EVA, PET, PC, paper, POLO, and OCA.

This makes it ideal for industries that require precise and clean cuts for high-performance applications, including electronics, automotive, and packaging sectors. Its advanced CNC system ensures accuracy and efficiency across various materials, providing versatile and reliable cutting solutions.

Key Features:

High-Precision Die-Cutting: The machine uses high-precision die-cutting technology, capable of cutting very intricate patterns and complex shapes, making it ideal for products requiring high precision.

Multiple Specifications: This die-cutting machine supports material widths and lengths of 350mm x 1600mm and 500mm x 2000mm, respectively, making it suitable for various product demands.

Automated Control: Typically equipped with advanced CNC control systems, it automatically adjusts cutting depth, speed, and other parameters to ensure efficient and precise processing.

Multi-Function Operation: It can perform multiple operations, including die-cutting, creasing, slitting, and waste discharge, making it ideal for one-stop processing.

Quick Die Change: The machine allows for fast die changes, which improves production efficiency and reduces downtime.

Application Areas:

Electronics Industry: Used for die-cutting thin films, protective films, adhesive tapes, and other materials used in devices like smartphones and tablets.

Automotive Industry: Suitable for producing precise components such as car dashboard films and headlamp films.

Medical Industry: For die-cutting fine medical device materials such as medical patches and sensors.

Label and Packaging: Precision die-cutting for various high-precision labels, stickers, and packaging materials.

Technical Specifications:

| Specifications | JG-350*1600 | JG-500*2000 |

| Feed Width | 360 mm | 510 mm |

| Max. Die Cutting Area | 1600 × 350 mm | 2000 × 500 mm |

| Max. Operating Speed | 6000 punches/hour | 6000 punches/hour |

| Punching Stroke | 20 mm | 20 mm |

| Pressure Regulation | 10 mm | 10 mm |

| Voltage Regulation Accuracy | 0.005 mm | 0.005 mm |

| Drawing Accuracy | ±0.1 mm | ±0.1 mm |

| Upper Form Size | 1600 × 380 × 2.5 mm | 2000 × 530 × 2.5 mm |

| Lower Template Size | - | - |

| Overall Dimensions | 3200mm × 1325mm × 1925mm | 3700mm × 1500mm × 1925mm |

| Machine Weight | 6500 kg | 8500 kg |

| Air Source Specification | 0.5–0.7 MPa | 0.5–0.7 MPa |

| Total Power | 13.5kW | 18 kW |

| Lubrication Mode | Intermittent fuel supply | Intermittent fuel supply |

| Applicable Die Types | Plywood mold, wood mold | Plywood mold, wood mold |

Performance Characteristics:

Small hole positioning instant correction device.

Double servo drive for stable pressure, low noise, and precise drawing.

Electric digital display for quick and convenient voltage adjustment.

High punching force with stable die-cutting pressure.

QDC mold allows multiple high precision nesting die cutting to be achievable.

Applications:

This machine is well-suited for industries that require precision die cutting for materials like plywood, wood, and other specialized molds. It is particularly useful in: