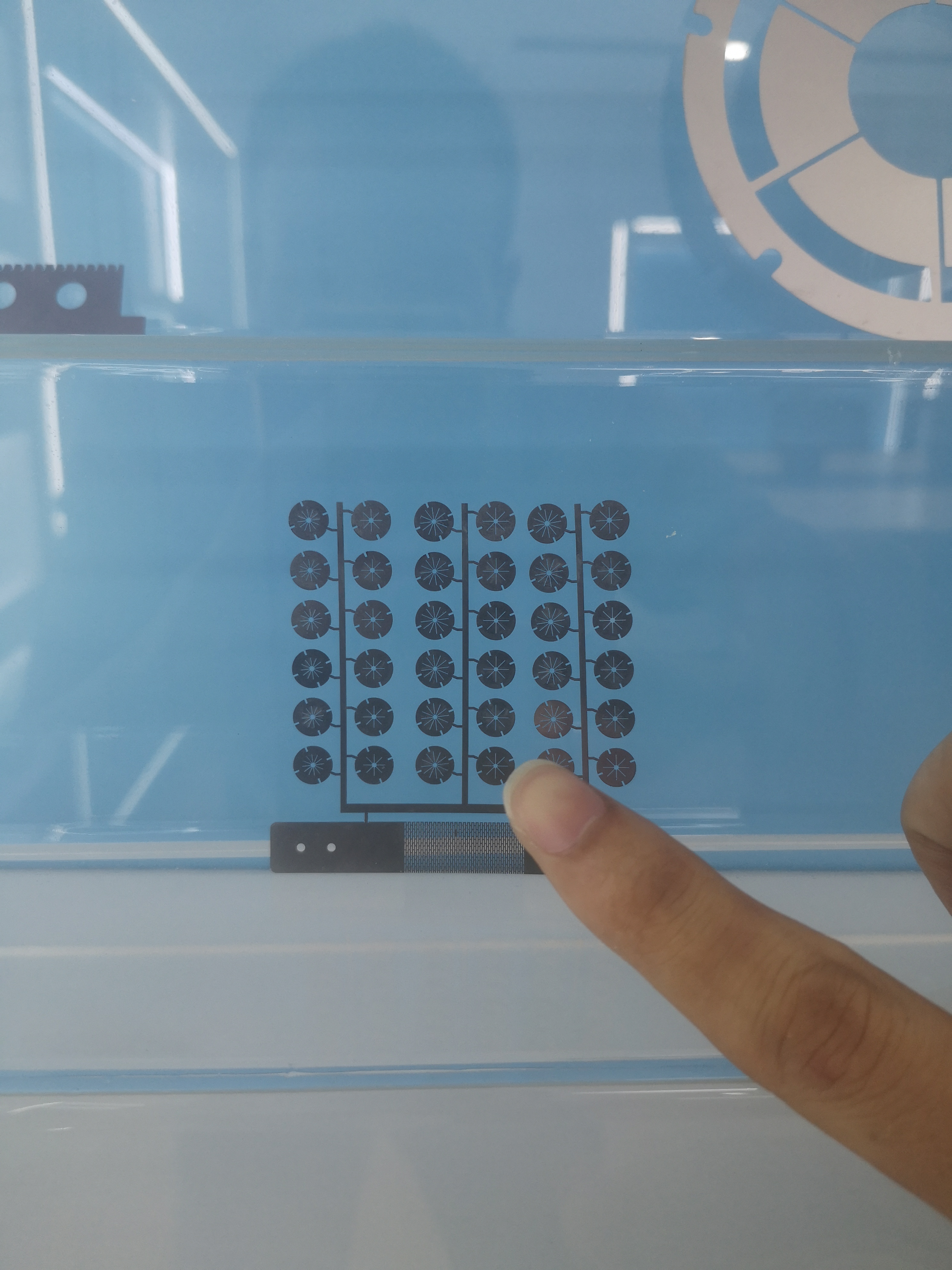

Support and Protection: Surface mount carriers securely hold PCBs in place during the SMT process, ensuring that delicate components are not damaged by handling or movement.

Versatility: These carriers are designed to accommodate various PCB types, including flexible and rigid-flex designs, making them highly versatile for different assembly processes.

Efficiency: By improving the handling and transport of PCBs, surface mount carriers help to significantly reduce setup time and improve the speed of the manufacturing process.

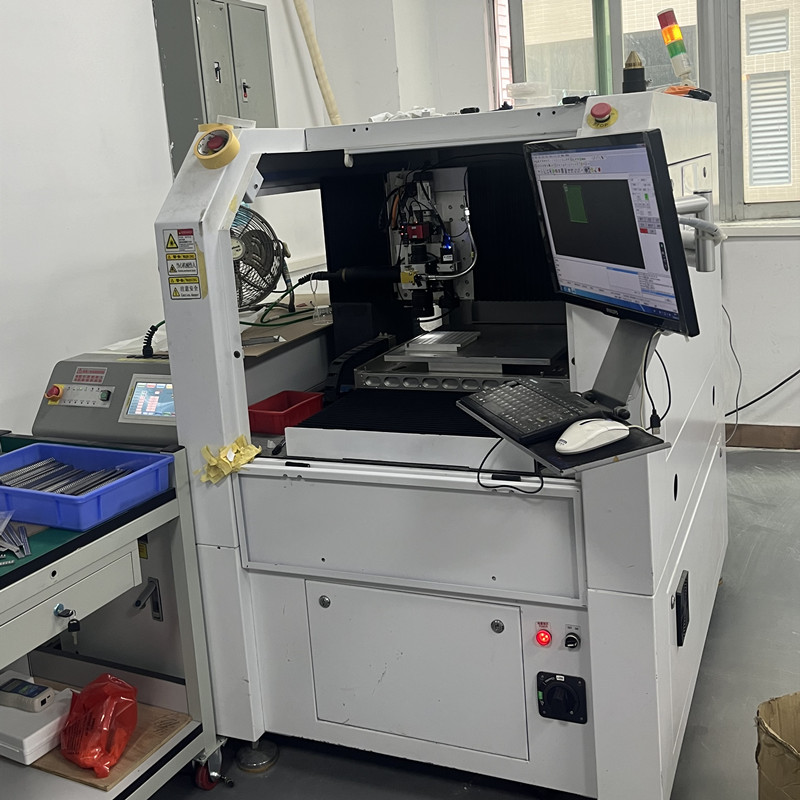

Laser-Cut Precision: The use of advanced laser technology ensures that the carriers are cut to precise dimensions, resulting in a high degree of accuracy and consistency. This is especially important when working with high-density, small-sized components on PCBs.

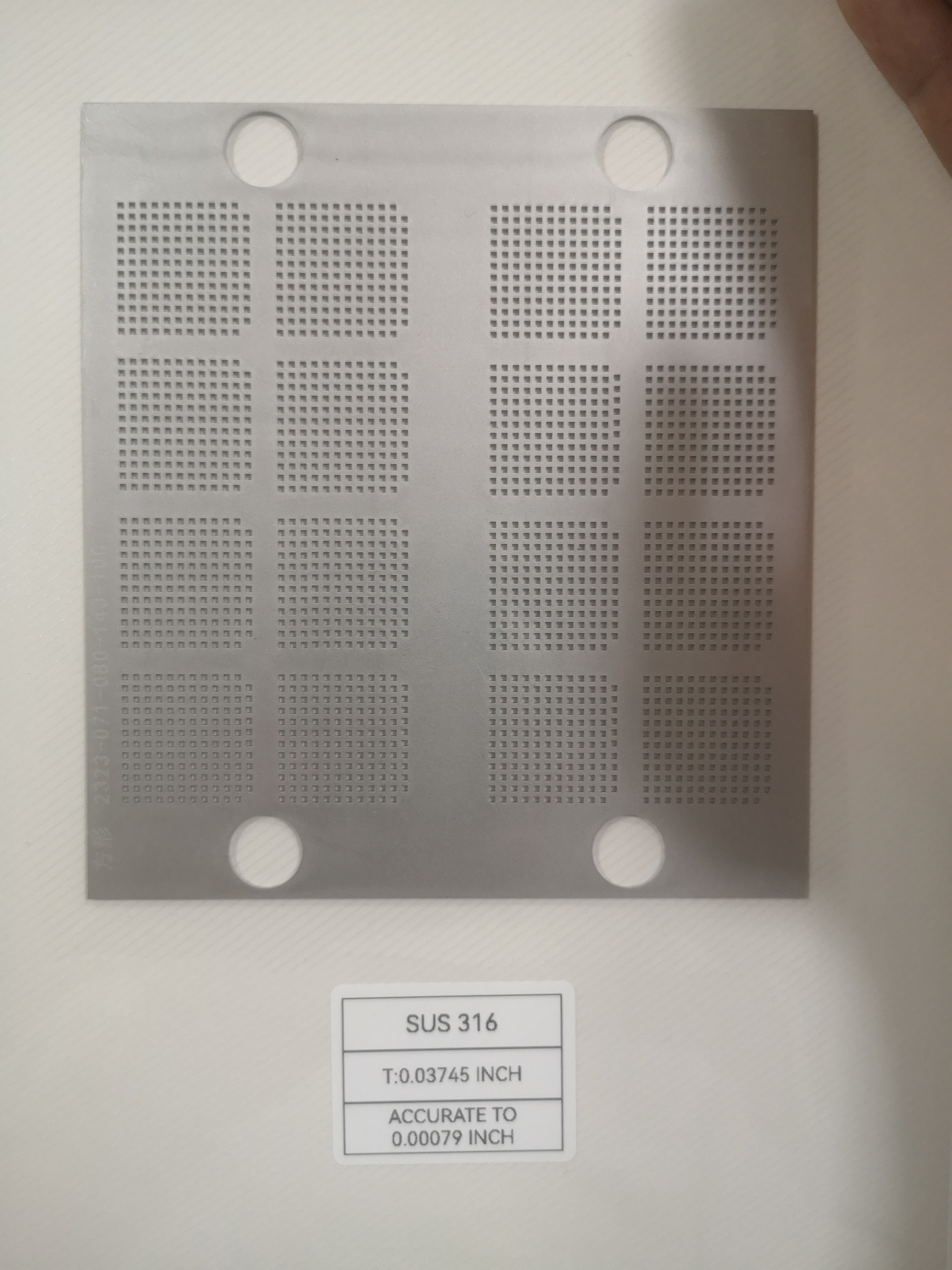

Materials: Stainless steel is commonly used for surface mount carriers due to its strength, durability, and resistance to corrosion. However, it is important to note that stainless steel fixtures should not be used during the reflow process, as they may interfere with the thermal management during soldering.

Customization: Surface mount carriers can be customized to meet specific needs based on the size, shape, and configuration of the PCBs being handled. This customization includes laser cutting of features such as slots, holes, and alignment markers.

Increased Production Efficiency: By improving the flow of PCBs through the assembly process and reducing the chances of human error, surface mount carriers help in optimizing the overall production cycle, leading to faster turnaround times and improved product quality.

No Tooling Costs: Laser cutting eliminates the need for expensive tooling, reducing costs and lead times associated with traditional manufacturing methods.

Engraving and Marking: In addition to laser cutting, surface mount carriers can also be laser-engraved with essential markings such as part numbers, company logos, or process-specific instructions, further enhancing traceability and quality control in the manufacturing process.