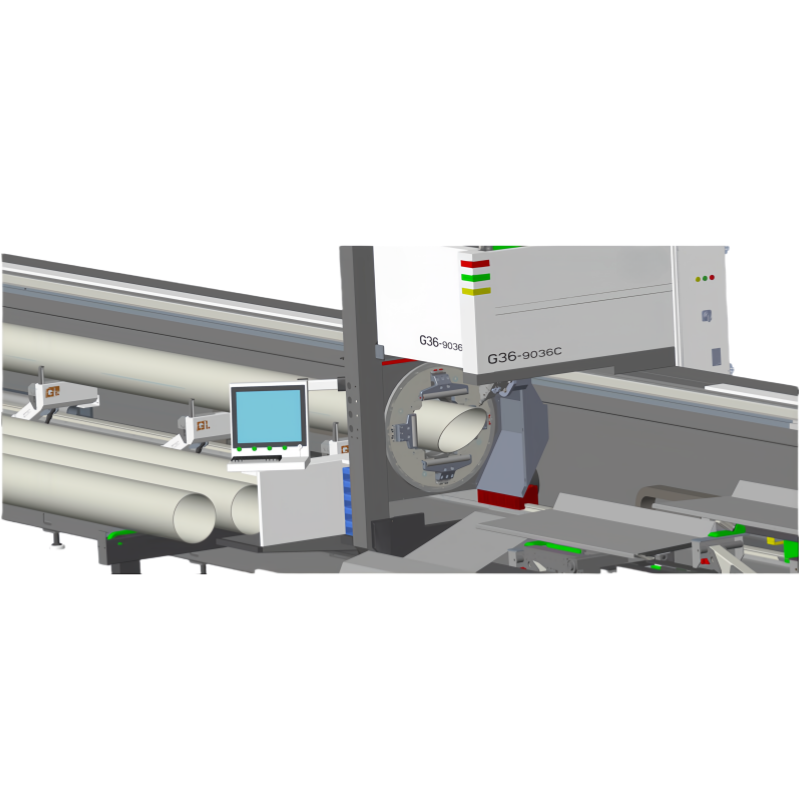

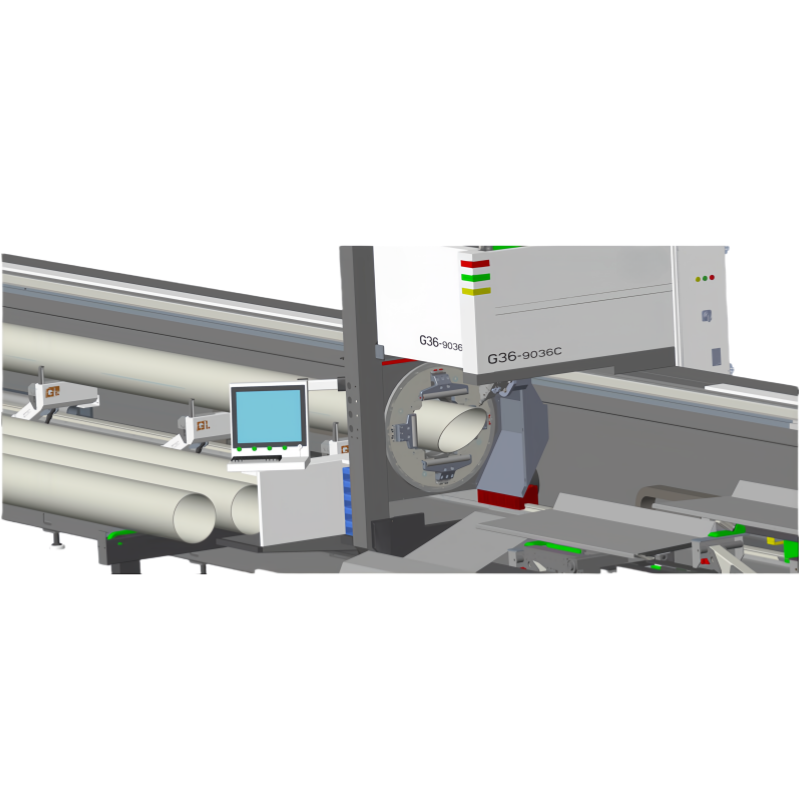

Model: G36-9036C-12000W

Platform: 9-Meter Heavy-Duty with 360mm Triple Chuck + Bevel Cutting Function

1. Product Overview

Applicable Tube Types & Sizes

Tube Types: Round, square, rectangular, oval, waist-shaped, H-beam, channel steel, angle iron, special profiles

Tube Size:

Industries: Steel structures, aerospace, automotive, garden machinery, agricultural equipment, fitness, smart furniture, e-bikes, escalator structures, and other tube-processing industries

Feeding & Automation

️ 2. Key Component Configuration

| No. | Component | Brand | Spec/Origin |

| 1 | Fiber Laser | Raycus/Max | 12,000W / China Tier-1 |

| 2 | Cutting Head | OSPRI/Qiangqiang | 12,000W / China Tier-1 |

| 3 | Gear Rack | YYC | M3 Grade 6 / Taiwan |

| 4 | Reducer | Motoreducer/Xinbao | P1 Precision / Domestic |

| 5 | Linear Guide | HIWIN | CGH45 H-grade / Taiwan |

| 6 | Servo Motor | YASKAWA | 4000rpm, bus driver / Japan |

| 7 | Oil Circuit | Baoteng | Auto lubricating / Domestic |

| 8 | Drag Chain | Langu | G80 rigid / Domestic |

| 9 | Chiller | Hanli/Tongfei | 12,000W / Domestic |

| Voltage Stabilizer | Xinbaoming | 120KW / Domestic |

| 10 | Electrical Components | Schneider | Made in China / France Brand |

| 11 | Pneumatics | Airtac | Made in China / Taiwan Brand |

| 12 | Bed Frame | In-house R&D | 17m, stress-relieved at 600°C |

| 13 | Chuck | In-house R&D | GL360 Triple Chuck, 500kg load |

| 14 | Support Rack | In-house R&D | 6 pcs, 500kg capacity |

| 15 | Loading System | Semi-automatic | 5 pipes / 1200kg loading |

| 16 | Unloading System | Servo Floating | 60kg/m, 4m area, max 9m support |

| 17 | CNC System | Bochu | Breakout 5000A Bus / Shanghai |

| 18 | Nesting Software | Bochu | 3D Tube Cutting / Shanghai |

| 19 | Operator Side | Left-hand drive | Standard |

| 20 | Packaging & Shipping | Standard | Standard |

3. Component Technical Specs

| Component | Property | Value |

| Laser | Output Power | 12000W |

| Mode | Fiber Continuous |

| Fiber Diameter | 50-100µm |

| Cooling Method | Water-cooled |

| Material Capability | Carbon steel, SS, Al alloy, copper |

| Bed Frame | Structure | Tube-plate welded |

| Length | 16 meters |

| Chuck | Model | GL360 |

| Mode | Pneumatic |

| Load Capacity | 500kg |

| Cutting Head | Focus Focal Length | 200mm |

| Collimation Focal Length | 100mm |

| Focus Adjustment Speed | 100mm/s (manual optional) |

| Assist Gas Pressure | ≤3Mpa |

| Chiller | Cooling Medium | Distilled/deionized water |

| Temp Settings | 30°C / 20°C adjustable |

| Temp Precision | ±0.1°C |

| Flow Rate | 10L/min |

| Head Lift | 20m |

4. Machine Specifications

| Category | Property | Value |

| Platform | Series | 360 Series Large Platform |

| Dimensions (LxWxH) | 16000x2600x2700 mm |

| Weight | 12~12.5 Tons |

| Max Power Consumption | 100~110 kW |

| Operating Temp | 0~40°C |

| Cutting Range | Travel | Round: Ø16~Ø360mm |

|

| Square: □16~□250mm |

|

| Rectangular: Max 300x200mm |

| Cut Width | 0.1-0.2 mm |

| Chuck | One-clamp Range | Ø16~Ø180mm (360 with jaw change) |

| Axis Travel | X/Y/Z/U | 9100/300/450 mm / ∞ rotate |

| Precision | X/Y Positioning Accuracy | ±0.04 mm/m |

| X/Y Repeatability | ±0.04 mm |

| U-Axis Repeatability | ≤6 arcmin |

| U-Axis Max Rotation Speed | 75 RPM |

| Speed | X/Y Max Acceleration | 0.8G |

| X/Y Rapid Traverse | 75 m/min |

| Loading | Auto Feed Length | 5800~9000 mm |

| Feed Cycle | First ≤70s, next ≤35s |

| Auto Feed Load | 1200kg total / 500kg per tube |

| Unloading | Tail Material | 0~50mm |

| Max Unload Length | 4000mm standard, 9000mm 3-chuck |

| Bevel | Swing Angle | ±45° programmable |

5. System Overview

Bed Frame: Stress-relieved at 600°C, precision-machined for rigidity & stability. Patented side-mounted bed design with matching auto-feeder for efficiency.

Gantry/X/Z Axis: Stress-relieved beams. Limit switches + elastic mechanical buffers for safe stroke ends. Z-axis uses servo motor with linear module for precise vertical motion.

Electrical Control: Bochu bus-type CNC system + YASKAWA servo for stable, responsive operation. Soft-keys & intuitive menu interface.

Software Features:

Real-time corner control, higher cutting efficiency (2× faster at turns)

Advanced piercing: segmented, progressive, pre-pierce

Fine parameter controls for laser, gas, follow height

Graphic preview with one-click start anywhere

Visual lead-in/out and kerf compensation

Auto pipe centering, auto rotation calibration

Electrical Safety:

⚡ Cutting Speed Reference (12000W)

Actual speed affected by gas purity, pipe quality. For reference only.

Utility Requirements

| Utility | Specification |

| Power | 380V ±5%, 50Hz, 3-phase, ≥100KVA, grounded ≤3Ω |

| Cooling | 60L distilled/deionized water, <10µS/cm |

| Oxygen | ≥99.6% purity, ≥1.0MPa, ≥1m³/min |

| Nitrogen | ≥99.99% purity, ≥2.5MPa, ≥2.5m³/min |

| Air | ≥1.3MPa, dew point ≤5°C, oil <0.003ppm |

Site Requirements

Temperature: 5~30°C (Laser in air-conditioned room preferred)

Humidity: <70%

Flat floor, no strong vibrations (add isolation grooves if needed)

Ground strength required, foundation prepped as per anchor drawings

Keep area clean, dust-free, dry, and interference-free (EMI safe)

End of technical file draft for G36-9036C-12000W