Laser Power: 3000W, offering high cutting speed and efficiency.

Compatible Materials: Carbon steel, stainless steel, aluminum alloy, copper, brass, and other metals.

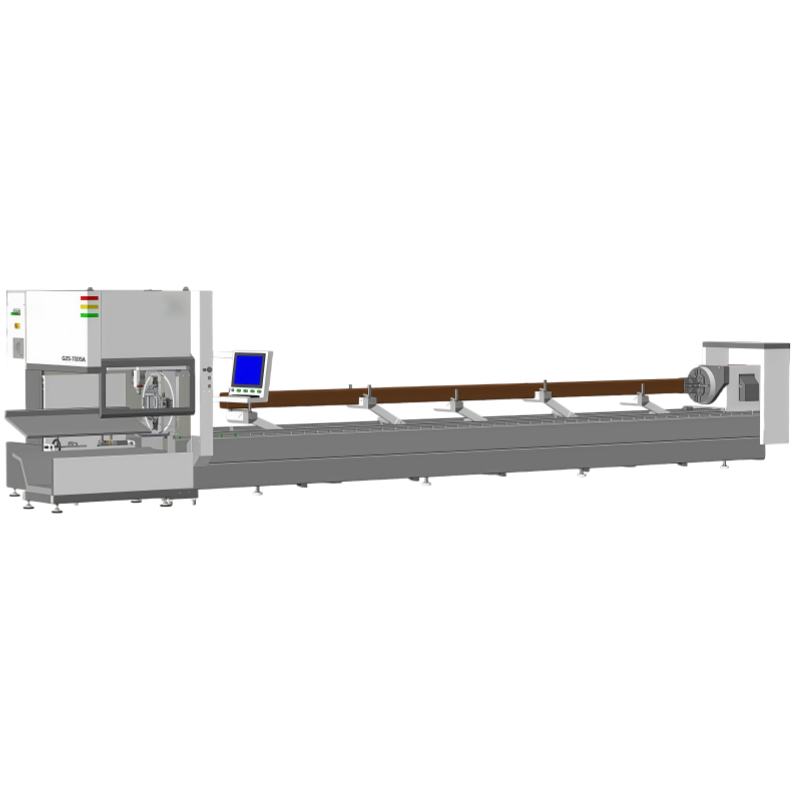

Tube Types: Round, square, rectangular, oval, elliptical, I-beams, U-beams, and more.

Chuck System: Dual-chuck configuration (GL-360), pneumatic, with a load capacity of up to 500 kg per chuck.

Cutting Area:

Operating Temperature: 0~40°C

Automatic Loading: Modular design allows for semi-automatic or fully automatic loading systems, with a customizable loading length based on customer needs.

Fiber Laser Source: Chuangxin/Heishi, 3000W, top-tier domestic brand.

Cutting Head: Osprey, 3000W automatic focus adjustment.

Gear and Rack: YYC, Taiwan, M2-6 grade, for enhanced precision.

Speed Reducer: MOTOREDUCER, 110-090.

Linear Guide: AIRTAC, Taiwan, CGH35, ensures smooth motion and accuracy.

Motor: Inovance/Optional Yaskawa, high-performance, up to 4000rpm.

Dust Extraction System: Optional, to keep the workspace clean.

Water Chiller: Hanli, 3000W, provides effective cooling for the laser system.

Electrical Components: Schneider, high-quality components for reliable control.

Air System: AIRTAC, Taiwan, provides precise pressure control.