Laser Power: 6000W, providing fast and efficient cutting for various materials.

Compatible Materials: Carbon steel, stainless steel, aluminum alloys, copper, brass, and other metals.

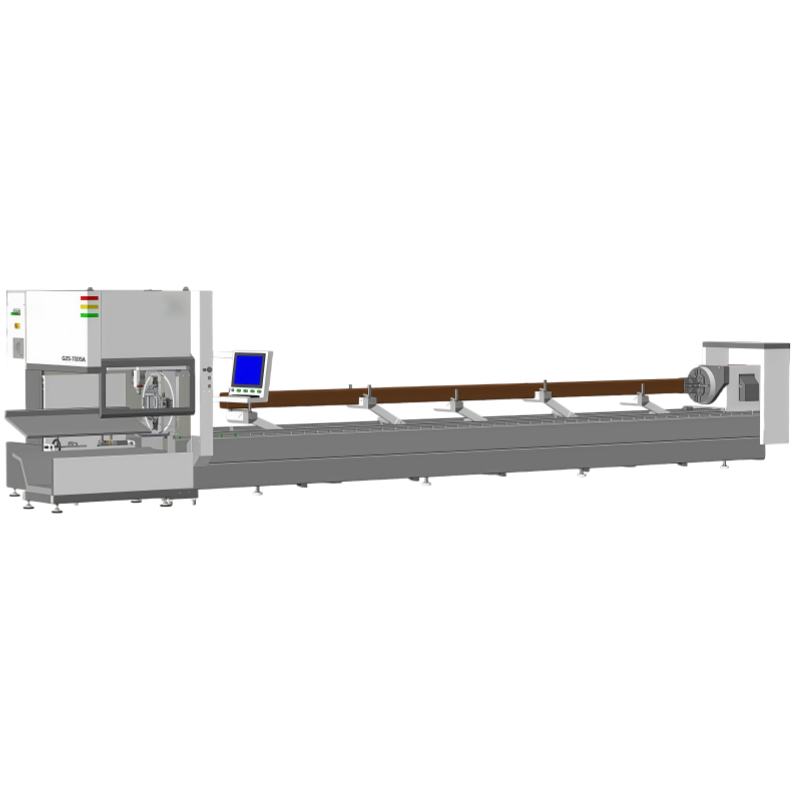

Tube Types: Round, square, rectangular, elliptical, oval, I-beams, U-beams, and custom profiles.

Cutting Area:

Automatic Loading System: Semi-automatic loading with modular options for full automation.

Max Material Load: 400 kg for manual loading, 320 kg for automatic loading.

Cutting Speed: High cutting speed due to the advanced 6000W laser source.

Fiber Laser Source: Chuangxin/Heishi, 6000W, leading domestic brand.

Cutting Head: OSPRI, designed for 6000W laser systems.

Gear and Rack: YYC, Taiwan, ensures high precision in movement.

Speed Reducer: MOTOREDUCER, from France, high-quality power transmission.

Linear Guide: HIWIN, Taiwan, for smooth and precise movement.

Motor: Inovance, high-performance, up to 4000rpm.

Oil System: Baoteng, domestic leading brand.

Drag Chain: Langu, for efficient cable management.

Water Chiller: Hanli, designed for 6000W fiber lasers.

Electrical Components: Schneider, providing reliable and stable electrical control.

Pneumatic Components: AIRTAC, Taiwan, for air pressure control.