200 Ton Bending Force:This press brake is equipped with a 200-ton bending capacity, providing ample force to bend thick and tough sheet metals. Whether you're working with stainless steel, carbon steel, aluminum, or other metals, this machine can handle a wide range of materials with precision and ease.

4100mm Bending Length:The 4100mm bending length enables the machine to accommodate larger workpieces, making it suitable for industries that require the bending of long metal sheets. This makes it versatile for handling various types of metal sheet, profiles, and plates, with uniform results across different sizes.

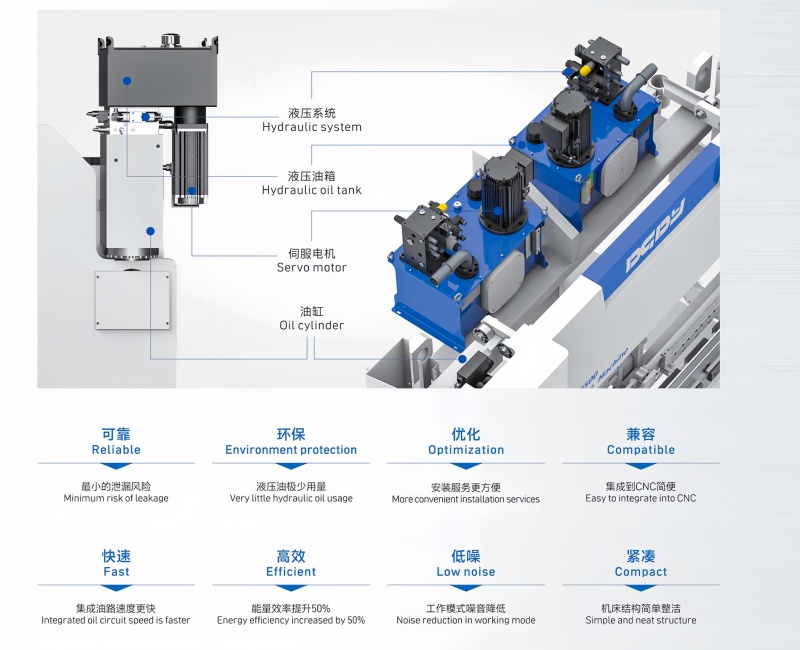

Electro-Hydraulic Servo Technology:The machine utilizes electro-hydraulic servo technology, which combines hydraulic power with the precision and energy efficiency of electric servo motors. This innovative hybrid system ensures smooth, controlled, and precise operation, with reduced energy consumption compared to traditional hydraulic systems. The electro-hydraulic design offers precise control over the bending process while maintaining high bending force and speed.

CNC Control System:The CNC (Computer Numerical Control) system provides advanced control over the bending operation, allowing for precise programming, automatic adjustments, and real-time monitoring. The intuitive user interface on the CNC system makes it easy for operators to input the desired bending parameters, such as angle, back gauge position, and stroke length, ensuring accuracy and repeatability in every bend.

Energy Efficiency and Cost Savings:One of the standout benefits of the electro-hydraulic servo system is its energy efficiency. The servo motors adjust their speed and power output based on the load, reducing electricity consumption during operation. This results in lower operating costs and a greener, more environmentally friendly machine. Compared to traditional hydraulic systems, the electro-hydraulic system minimizes energy waste, making it a cost-effective solution for high-volume production environments.

High Precision and Accuracy:The advanced CNC system ensures that the bending process is highly accurate, with the machine capable of producing bends to within fractions of a millimeter. The precise control of the ram position, stroke depth, and back gauge allows for consistent, repeatable results across different bending jobs, ensuring that each component meets the required specifications.

Back Gauge and Ram Control:The machine features a CNC-controlled back gauge system that ensures precise positioning of the metal sheet during the bending process. The back gauge adjusts automatically according to the programmed specifications, reducing setup time and ensuring uniform bending for multiple parts. Additionally, the automatic ram positioning system ensures precise control of the downward stroke, improving accuracy and reducing the likelihood of errors.

Fast Approach and Return Speeds:The machine is designed to optimize cycle time, with fast approach speeds and quick return speeds. This reduces downtime between bends, increasing the overall productivity of the machine. The faster cycle times contribute to higher throughput, especially in high-demand, repetitive manufacturing settings.

User-Friendly Interface:The CNC control system features an intuitive, user-friendly interface with a touchscreen display that simplifies programming and operation. Operators can easily input bending parameters, monitor machine performance in real time, and make adjustments on the fly. The control system also stores programs for frequent jobs, reducing setup time and ensuring consistency between batches.

Safety Features:This press brake comes equipped with a wide range of safety features, including light curtains, safety shields, and emergency stop buttons. The CNC system continuously monitors the machine’s performance and alerts operators to potential safety risks or mechanical faults. These features ensure that the operator can work safely and efficiently, reducing the risk of accidents.

Durability and Maintenance:The machine is built with durability in mind. Constructed from high-quality materials, it is designed for long-term reliability, even in harsh industrial environments. Routine maintenance tasks such as oil changes, filter replacements, and component inspections are made easier with the machine’s modular design, which facilitates quick repairs and minimizes downtime.

Versatility for Various Applications:This press brake is highly versatile, making it suitable for a wide range of applications across various industries. It can be used for bending sheet metal in applications such as automotive manufacturing (for body panels, brackets, and chassis), aerospace (for fuselage and wing components), construction (for metal structural parts), and general metal fabrication (for custom parts and machinery).

Automotive Industry:The 200T press brake is ideal for producing automotive components such as body panels, chassis, brackets, and structural components. Its high precision and large bending length make it suitable for manufacturing large parts used in vehicle construction.

Aerospace Manufacturing:Aerospace components require high accuracy and precision. This machine is perfect for producing parts like aircraft fuselage panels, wing components, and structural parts that require consistent quality and exact dimensions.

General Sheet Metal Fabrication:The machine is a perfect fit for general sheet metal fabrication, where large batches of parts must be bent to precise specifications. It can handle complex metalworking tasks with ease, from industrial machinery components to custom designs for various metal products.

Construction and Infrastructure:In the construction industry, the press brake is used for bending structural components like beams, columns, and metal frames. It is essential for producing large, high-strength parts that are used in building and infrastructure projects.

HVAC and Electrical Equipment:The machine is also ideal for producing parts used in HVAC systems, electrical enclosures, and other industrial equipment. It can handle a variety of metals, including mild steel, stainless steel, and aluminum, offering flexibility in material selection.