Industrial Nitrogen Generators for Laser Welding

ZHN-L Series Laser Welding Nitrogen Generators

ZHN-02L Laser Welding Nitrogen Generator

Overview

The ZHN-02L Laser Welding Nitrogen Generator is a high-performance, medium-capacity on-site nitrogen production system designed specifically for laser welding applications. With a nitrogen output of 40 NL/min and a purity range from 95% to 99.999%, it ensures a stable, reliable, and cost-effective nitrogen supply for manufacturing facilities and workshops.

This unit integrates advanced gas separation technology, a robust control system, and an easy-to-use interface, making it the ideal solution for companies looking to improve welding quality, reduce operational costs, and eliminate dependence on bottled nitrogen deliveries.

Key Advantages

On-Demand Nitrogen Supply – No delays, no running out of gas during production.

High Purity Output – Adjustable purity from 95% up to 99.999% to suit various materials and welding requirements.

Cost Savings – Eliminates recurring cylinder rental, transportation, and refilling costs.

Stable Flow Rate – Consistent nitrogen delivery of 40 NL/min for uninterrupted welding.

Compact and Durable Design – Small footprint, heavy-duty construction for long service life.

Main Features

1. PLC Intelligent Control

Equipped with an advanced Programmable Logic Controller (PLC), the ZHN-02L offers intelligent, fully automated operation.

Real-time monitoring of purity, pressure, and flow

Automatic system adjustment for efficiency and stability

Integrated alarm system for maintenance reminders and fault detection

Optimized energy usage to reduce operational costs

2. Built-in Refrigerated Air Dryer

Moisture can damage welding quality and nitrogen separation equipment. The built-in refrigerated air dryer ensures:

Dry compressed air before entering the nitrogen separation system

Prevention of oxidation and contamination in welding

Extended lifespan of filters and membranes

3. Triple Filtration System

The ZHN-02L is equipped with three stages of filtration to achieve ultra-pure nitrogen:

Pre-Filter: Removes large particles, water, and oil mist

Fine Filter: Eliminates smaller particles and oil aerosols

High-Efficiency Filter: Guarantees nitrogen purity for critical welding applications

4. Automatic Drainage System

Automatic condensate drainage minimizes manual maintenance and prevents moisture accumulation in the system, ensuring stable long-term operation.

5. Direct Air Compressor Connection

The generator can be connected directly to an existing air compressor for immediate nitrogen production, reducing installation time and eliminating the need for external storage tanks.

6. 7-Inch Multilingual Touchscreen

An industrial-grade, full-color touchscreen provides:

Real-time system status and performance data

Quick access to settings and controls

Multilingual support for international operations

Easy-to-use interface for operators at any skill level

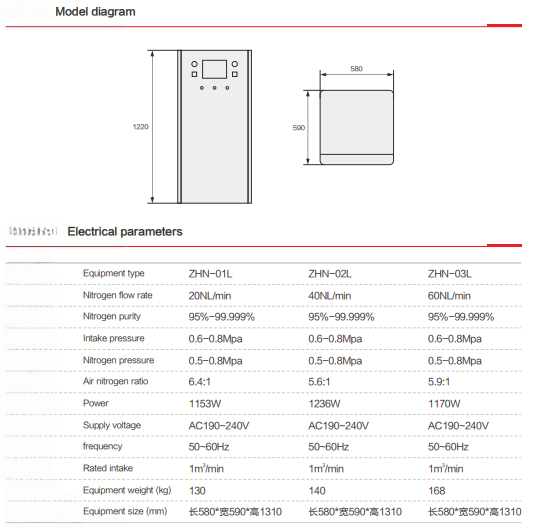

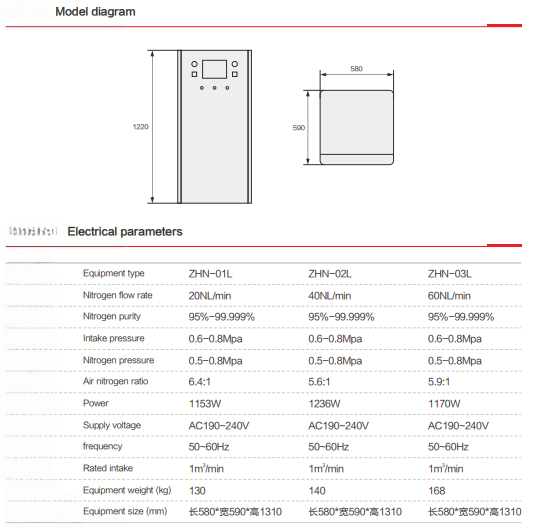

Technical Specifications

| Model | Nitrogen Flow Rate | Nitrogen Purity | Intake Pressure | Nitrogen Pressure | Air:Nitrogen Ratio | Power | Supply Voltage | Frequency | Rated Intake | Weight (kg) | Dimensions (mm) |

| ZHN-02L | 40 NL/min | 95% – 99.999% | 0.6 – 0.8 MPa | 0.5 – 0.8 MPa | 5.6 : 1 | 236 W | AC 190–240 V | 50–60 Hz | 3.1 m³/min | 140 | 580×590×1310 |

Applications in Laser Welding

The ZHN-02L is designed for a wide range of laser welding environments, including:

Fiber Laser Welding Machines – Consistent nitrogen protection for high-precision joints.

Handheld Laser Welders – Portable nitrogen support for small-batch and repair welding.

Robotic Welding Cells – Stable gas supply for automated production lines.

Special Material Welding – Stainless steel, aluminum alloys, titanium, and more.

Benefits in welding applications:

Oxidation Prevention: Protects molten metal from reacting with oxygen during welding.

Improved Weld Appearance: Produces smoother, shinier weld beads.

Reduced Porosity: Enhances weld strength by minimizing gas bubbles.

Consistent Quality: Ensures repeatable results for every weld.

Why Choose the ZHN-02L Over Gas Cylinders?

| ZHN-02L Nitrogen Generator | Traditional Gas Cylinders |

| On-demand nitrogen production | Limited gas supply, risk of shortages |

| Adjustable purity (95–99.999%) | Fixed purity from supplier |

| No transportation costs | Ongoing delivery and rental fees |

| Low operating cost | High recurring cost per cylinder |

| Compact footprint | Requires storage space for multiple cylinders |

Installation & Operation

The ZHN-02L is plug-and-play with minimal installation requirements:

Connect to your compressed air source.

Connect nitrogen outlet to the welding machine.

Power on and select desired purity and flow.

Once started, the PLC system automatically manages production, maintaining optimal purity and flow without manual adjustments.

Maintenance & Service

The ZHN-02L is designed for low-maintenance operation:

Filter replacements are quick and tool-free

Automatic condensate drainage reduces manual intervention

Long-life components minimize downtime

Diagnostic functions help identify issues before they affect production

Our global after-sales network offers technical support, spare parts, and training to ensure your equipment always performs at its best.