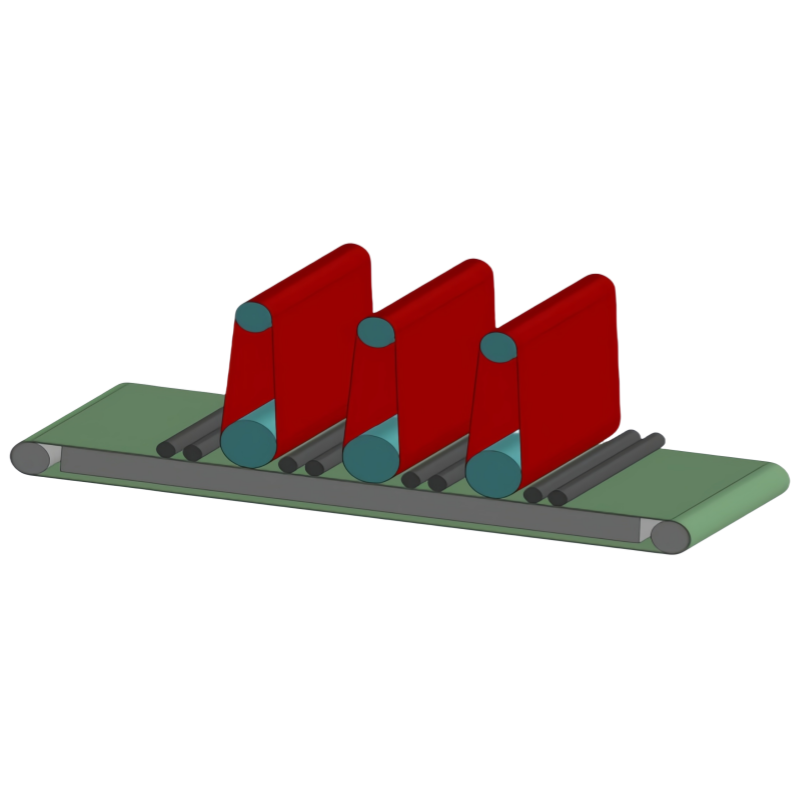

630mm 3-Belt Sanding Machine Sanding Belts Belt Sander Sandpaper 180 240 320 400 600 Grit: Product Overview

The 630mm 3-Belt Sanding Machine is a highly efficient and powerful industrial-grade equipment designed to meet the most demanding metal finishing, surface preparation, and deburring requirements. Whether you're working with carbon steel, stainless steel, aluminum, or other non-ferrous metals, this wide belt sander offers precision and versatility for sanding, polishing, and finishing a variety of materials. Equipped with a three-belt sanding system, it provides a smooth and consistent finish while handling larger workpieces with ease.

This machine is ideal for companies in industries such as automotive manufacturing, metal fabrication, aerospace, and more, offering superior performance in a range of tasks from heavy material removal to fine polishing and sanding. With the option to choose from sanding belts of various grits—180, 240, 320, 400, and 600—this machine provides flexibility for a wide range of metal surface treatments.

Technical Specifications

| Parameter | Unit | R630 | RR630 | RP630 | RRR630 | RRP630 |

| Maximum Working Width | mm | 630 | 630 | 630 | 630 | 630 |

| Maximum Working Height | mm | 60 | 60 | 60 | 60 | 60 |

| Minimum Working Length | mm | 220 | 220 | 220 | 220 | 220 |

| 1st Sanding Belt Power | kW | 15 | 15 | 15 | 15 | 15 |

| 2nd Sanding Belt Power | kW | - | 11 | - | 11 | 11 |

| 3rd Sanding Belt Power | kW | - | - | - | 11 | - |

| Polishing Wheel Power | kW | - | - | 11 | - | 11 |

| Rotary Motor Power | kW | - | - | - | - | - |

| Feeding Motor Power | kW | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 |

| Lifting Motor Power | kW | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 |

| Oscillation Motor Power | kW | - | - | 1.5 | - | 1.5 |

| Vacuum Motor Power | kW | - | - | - | - | - |

| Machine Dimensions | m | 1.8×1.9×2 | 2.1×1.9×2 | 2.1×1.9×2 | 2.4×1.9×2 | 2.4×1.9×2 |

| Machine Weight | kg | 1400 | 1600 | 1600 | 1800 | 1800 |

| Sanding Belt Size | mm | 1900×630 | 1900×630 | 1900×630 | 1900×630 | 1900×630 |

Machine Model Overview

R630 / RR630 / RP630 / RRR630 / RRP630

R630: Ideal for applications requiring high sanding power and efficiency with basic configurations. This model provides significant sanding capacity and smooth surface finishes for medium-sized workpieces.

RR630 / RP630: These models come with enhanced motor power, including additional power for the second sanding belt. The RR630 and RP630 configurations allow for more specific finishing and deburring capabilities with multiple sanding belts, providing a more polished finish on metal surfaces.

RRR630 / RRP630: These are the top-tier models in the range, designed with high-end features, including multiple sanding belts, polishing wheels, and oscillation motors for additional finishing stages. The RRR630 and RRP630 can handle complex deburring and surface treatment tasks with precision.

Applications

The 24.8-inch (630mm) Wide Belt Sanders are commonly used in a variety of industries for processing different types of metal, including:

Automotive Manufacturing: Surface preparation for parts like body panels, chassis components, and engine parts.

Metal Fabrication: Finishing of cut or welded parts from steel, aluminum, and other metals, ensuring a smooth and consistent surface.

Aerospace: Precision sanding and deburring of metal parts used in aircraft manufacturing.

Heavy Equipment Manufacturing: Calibration, deburring, and surface finishing of large metal components.

Construction: Sanding and finishing of metal profiles, pipes, and steel plates used in building structures.

1. Powerful 3-Belt Sanding System

The 630mm 3-Belt Sanding Machine utilizes a powerful multi-belt system that ensures efficient, high-performance sanding. This system features three sanding belts, each tailored for specific tasks like material removal, fine sanding, and polishing. Each belt has been optimized for different grit sizes, ranging from 180 to 600, enabling operators to achieve a wide range of finishes on metal surfaces.

First Belt (Coarse Grit): Typically equipped with lower grit sizes (e.g., 180 or 240), this belt is perfect for heavy material removal, such as deburring, dross removal, or surface leveling. It can quickly remove surface imperfections and prepare the material for finer sanding.

Second Belt (Medium Grit): This belt usually comes with grits around 320 or 400. It provides a finer sanding finish and is used to further smooth and refine the workpiece surface.

Third Belt (Fine Grit): The third belt, often in the range of 600 grit, is used for final finishing and polishing. It ensures a smooth, high-quality surface finish, ideal for tasks that require precision and a refined look.

The three-belt system ensures that each stage of the sanding process is optimized for performance, giving the operator a consistently high-quality result, whether for deburring or surface polishing.

2. Wide Belt Width for Large Workpieces

With a 630mm (24.8-inch) sanding width, this machine is capable of processing larger workpieces and sheets with efficiency. This wide belt design ensures that even sizable metal components, like large plates, panels, and other large-scale parts, can be processed without compromising performance or finish quality.

The wide belt configuration also allows for even pressure distribution across the entire workpiece, providing uniform sanding and finishing. This is especially important in industries where consistency is key, such as automotive manufacturing or metal fabrication.

3. Adjustable Sanding Belt Tension System

The machine features an advanced tensioning system that allows the operator to adjust the tension of the sanding belts to suit the specific material being processed. This feature helps prevent the belts from slipping or becoming damaged during operation, ensuring a smooth and uninterrupted sanding process. It also allows for better control over the level of pressure applied during sanding, which is essential for achieving desired surface finishes.

4. Efficient Dust Collection System

Sanding operations can generate a significant amount of dust, especially when processing metal. The 630mm 3-Belt Sanding Machine comes equipped with a high-efficiency dust extraction system designed to remove dust and debris effectively during operation. This helps maintain a clean work environment, reduces airborne particles, and ensures that the sanding belts do not become clogged, thus maintaining their efficiency and lifespan.

The dust collection system also minimizes the risk of debris buildup on the workpiece, which could potentially affect the finish or damage the machine. A clean sanding process contributes to higher-quality finishes and increases machine longevity.

5. Flexible Grit Selection for Versatile Applications

This machine is compatible with a wide range of sanding belts, including various grit sizes to meet diverse finishing needs:

180 Grit: Ideal for heavy material removal, deburring, and surface preparation.

240 Grit: Suitable for medium sanding and material leveling, often used for initial stages of finishing.

320 Grit: Fine sanding for smoother surfaces and moderate polishing.

400 Grit: A finer grit for finishing and refining metal surfaces, reducing visible scratches from earlier sanding stages.

600 Grit: The finest grit option, perfect for polishing and achieving a smooth, high-quality finish suitable for precision applications.

With the ability to choose from a variety of grits, the 630mm 3-Belt Sanding Machine is highly versatile, catering to different stages of the sanding process from heavy-duty deburring to final, ultra-smooth finishes.

6. Enhanced Durability and Performance

Constructed with high-quality components, the 630mm 3-Belt Sanding Machine is designed to handle demanding industrial environments. The heavy-duty frame and robust sanding mechanism ensure long-lasting performance, even in continuous operation. This machine is engineered to withstand the wear and tear associated with regular use, reducing maintenance requirements and increasing uptime.

7. User-Friendly Controls

The machine is equipped with an easy-to-use control interface, making it accessible for both experienced operators and newcomers. With intuitive controls for belt tensioning, sanding speed adjustments, and grit selection, operators can fine-tune settings based on the material and desired finish. The ability to adjust parameters such as sanding pressure and belt speed allows for complete control over the sanding process, ensuring high-quality results every time.

Applications

The 630mm 3-Belt Sanding Machine is ideal for a variety of metalworking applications, including but not limited to:

Deburring: The machine is highly effective at removing burrs and sharp edges from metal parts, such as those created by laser cutting, punching, or plasma cutting. The use of coarse grits (e.g., 180 or 240) helps eliminate burrs quickly and efficiently.

Dross Removal: The first belt, equipped with a coarse grit, can also be used to remove dross and slag from metal surfaces, a common byproduct of welding and cutting processes. This ensures a clean surface, which is essential for subsequent finishing stages.

Edge Rounding: The machine is perfect for rounding off sharp edges, a crucial step in metalworking to prevent injury or damage during handling and assembly.

Surface Finishing: From rough sanding to fine polishing, this machine is capable of delivering consistent finishes on metal surfaces. Different grits allow operators to achieve the desired level of smoothness, from coarse to mirror-like finishes.

Polishing: With the fine grit belts, the machine can achieve high-quality polished finishes that are visually appealing and functionally essential in certain applications, such as automotive parts, appliances, and decorative metal products.

Calibration and Dimensioning: The machine can also be used for precise calibration of metal surfaces, ensuring uniform thickness across the entire workpiece, a critical task in many industries.

Technical Specifications

Maximum Working Width: 630mm (24.8 inches)

Maximum Working Height: 60mm

Minimum Workpiece Length: 220mm

Sanding Belt Power:

First Belt: 15kW

Second Belt: 11kW

Third Belt: 11kW

Polishing Wheel Power: 11kW

Feeding Power: 1.5kW to 2.2kW (depending on model)

Lift Power: 0.37kW

Swing Motor Power: 1.5kW

Machine Dimensions: 1.8 x 1.9 x 2 meters (varies with model)

Weight: 1400kg to 1800kg (depending on model)

Sanding Belt Size: 1900mm x 630mm