Dapeng Laser 3W UV Laser Inkjet Printer Perfectly Delivered to Zambia Customers in Africa

Recently received good news from the Ministry of Foreign Trade, Dapeng Laser 3-watt UV laser inkjet printer was delivered to Zambia customers in Africa perfectly. This marks that the number of Dapeng laser products sold to overseas countries and regions has risen to 26. With richer product research and development capabilities and stricter quality control management, Dapeng laser products have been recognized by more and more customers at home and abroad. Chemical laser equipment manufacturers move forward!

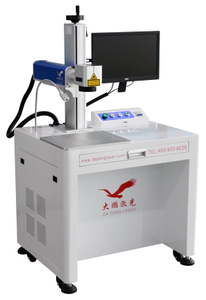

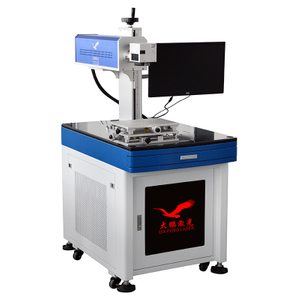

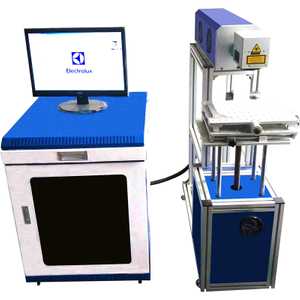

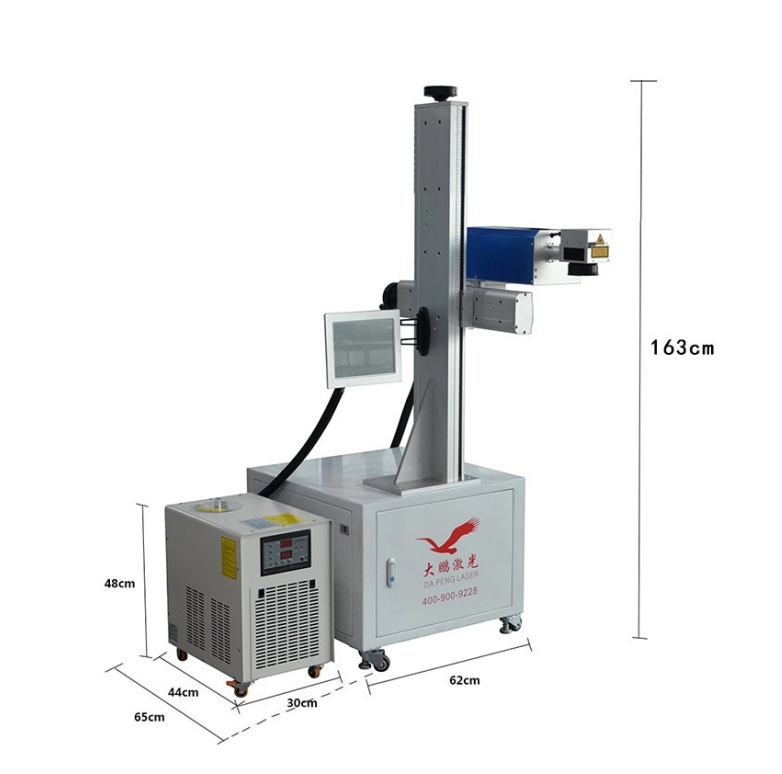

1: Equipment Name: 3W UV Laser Inkjet Printer

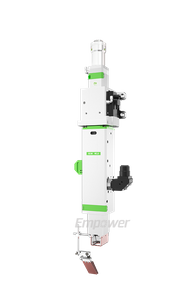

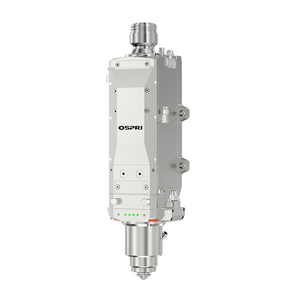

2: Product pictures:

3: main technical parameters

Category | Model Specifications | PM-UV-3-AOC-02 |

Laser characteristics | Center wavelength | 355nm |

Laser power | >3W |

repeat frequency | 30-150KHz |

beam quality | M2<1.5 |

Pulse Width | <15ns |

spot diameter | ~0.5mm |

Security Level | Class IV |

tag parameter | Marking speed | ≤15000mm |

Repeatability | ±0.001mm |

minimum character | 0.12mm |

Minimum marker line width | ≤0.01mm |

Mark range | 110x110mm(70mm/150mm/180mm/220mm) |

Other parameters | cooling method | water cooling |

System protection level | IP54 |

Operating Environment Requirements | Ambient temperature 15-35℃, relative humidity 30%≤RH≤85%, no oil mist, no condensation |

power requirements | AC220V±5%,50HZ/60HZ,5Amp |

Machine power consumption | <1.6KW |

Total Weight | About 120~130kg (without packaging) |

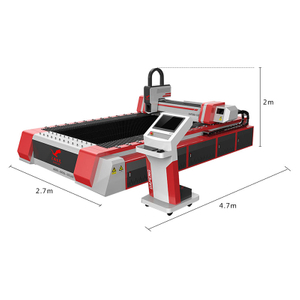

Overall dimensions of the machine in mm (length X width X height) | 500*500*1600 |

working principle:

Incorporating international advanced technology, high-energy ultraviolet photons directly destroy the molecular bonds on the surface of many non-metallic materials, so that the molecules are separated from the object. This method does not generate high heat, the ultraviolet laser has a very small focus spot, and the processing has almost no thermal influence. Therefore, it is called cold working, so it is suitable for ultra-fine marking and engraving of special materials.

product advantages:

⊙ Covering the entire application range of inkjet machines, it is no longer simply marking the product date and batch number, but also has unique visual and tactile effects and the characteristics of never rubbing, with strong anti-counterfeiting and anti-smuggling characteristics. .

⊙Ultraviolet laser has a short wavelength and a smaller focusing spot, which can realize ultra-fine marking;

⊙It belongs to cold working, the heat affected zone is small, to avoid damage to the processed material, and the yield is high;

⊙ Wide range of applicable materials to make up for the lack of infrared laser processing capability;

⊙Using high-speed digital galvanometer, the marking speed is fast, the efficiency is high, and the precision is high;

⊙ No consumables, low cost of use and maintenance; stable performance of the whole machine, long-term operation.

Industry application: ⊙Suitable for surface marking and micro-hole processing of glass, polymer materials and other objects.

⊙It is widely used in the surface marking of the packaging bottles (boxes) of polymer materials such as food, medicine, cosmetics, wires, etc.

⊙ Flexible PCB board, LCD, TFT marking, dicing and cutting, etc.

⊙Metallic or non-metallic coating removal

Features:

Nearly perfect marking quality: 355nm output wavelength reduces the thermal impact on the workpiece; galvanometer type high-precision marking head, the marking effect is fine and can be processed repeatedly; high-precision and meticulous light spot ensures perfect marking results; marking The process is non-contact, and the marking effect is permanent:

Wide range of application areas:

It is more suitable for processing materials that have a large reaction to heat radiation; it can cooperate with the production line, automatic loading and unloading, automatic feeding and discharging; suitable for marking on most metal and non-metal materials;

Laser inkjet printers are mainly used for supporting laser marking equipment in assembly lines or rapid automated production. It is mainly used for online coding and marking on the surface of various products or outer packaging. Unlike traditional laser marking machines that can only mark static objects, in the process of coding and marking, The product flows continuously on the production line, which greatly improves the production efficiency, with high efficiency, long life and less maintenance.

Software functions: ⊙Professional custom coding software, simple and convenient operation, convenient and fast refueling operation, and high degree of flexibility.

⊙The operation process is user-friendly, and the equipment is stable; ⊙Automatically generate various serial numbers, production dates, one-dimensional codes, two-dimensional codes

Working environment requirements:

⊙The ambient temperature is required to be between 15-35℃, and air conditioners are required;

⊙30%≤RH≤85% (RH relative humidity: refers to the ratio of the mass of water vapor contained in a humid air to the mass of water vapor contained in saturated air at the same temperature and pressure, this ratio is expressed as a percentage.) There is a risk of condensation on the device in the humidity range, and an air conditioner needs to be installed when using it;

⊙ Power supply grid requirements: 220V; 50HZ/60HZ;

⊙ Power supply grid fluctuation: ±15%, the grid ground wire meets international requirements. In areas where the voltage amplitude is more than 15%, electronic automatic voltage stabilization and current stabilization devices should be installed;

⊙ There should be no strong electromagnetic signal interference near the installation equipment. Avoid radio transmitting stations (or relay stations) around the installation site;

⊙ Foundation amplitude: less than 50Um; vibration acceleration: less than 0.05g. Avoid a large number of punching and other machine tools nearby;

⊙The equipment space is required to be smoke-free and dust-free, and avoid the working environment with serious dust such as metal polishing and grinding;

⊙Air pressure: 86-106kpa

⊙In some environments, anti-static floors should be installed, and shielding should be strengthened;

⊙There are strict requirements on the water quality of the working cooling circulating water. It is required to use pure water, deionized water or distilled water, and liquids containing high metal ions or other minerals such as tap water and mineral water cannot be used.

1. After-sales service:

Service Commitment: (Foreign)

1. Provide wooden boxes and send them to the supplier's port, and the buyer is responsible for shipping and customs duties.

2. The supplier provides a one-year warranty for the accessories. During the warranty period, the supplier guarantees the accessories returned by the buyer.

3. During the warranty period, the buyer needs the supplier on-site service, and the supplier is free of labor, but all travel, accommodation and visa expenses are borne by the buyer.

Service Commitment: (Domestic)

4. After the acceptance of the equipment, the quality guarantee period of the whole machine is one year. The system already includes a one-year service and spare parts warranty period. If there is a quality problem with the system components during the warranty period, our company's well-trained service engineers will provide telephone or on-site service at any time.

5. During the warranty period of the equipment, our company is responsible for free replacement of parts and services for any damage or damage caused by the quality of the equipment itself, except for conventional consumables (such as optical lenses, cutting nozzles) and those that are responsible for the user's illegal operation. .

6. After the installation, commissioning and acceptance of the equipment is completed, our company can send a technician to guide the user on-site for 1-7 days to help the user solve the problems that may be encountered during the initial use of the equipment.

7. Our company provides lifelong maintenance services for the products provided, and provides daily consultation and guidance related to equipment at any time. Outside the warranty period, our company still provides extensive and preferential technical support and spare parts supply for the buyer.

8. Our company reserves long-term free and high-quality operation and maintenance technicians for customers who have been strictly trained by our company, and is always ready to serve customers. Solve the troubles of customers looking for technicians.

9. After the device leaves the factory, our company will establish a "user profile card" to track and record the relevant information of the user using the device. After the equipment maintenance service is completed, our company will report the cause of the failure, the remedial measures, the time and date of completing the maintenance and returning to normal, etc. to the buyer, and the report will be made in duplicate for future reference.