Dapeng Laser invites you to visit the 7th China-Asia-Europe Expo in Urumqi from August 25th to 30th

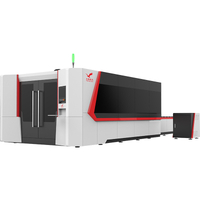

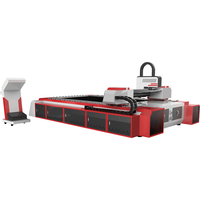

laser cutter

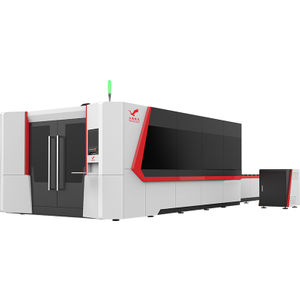

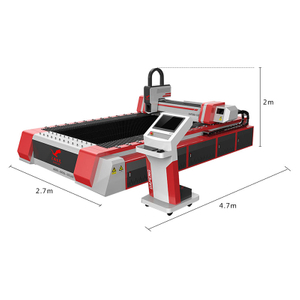

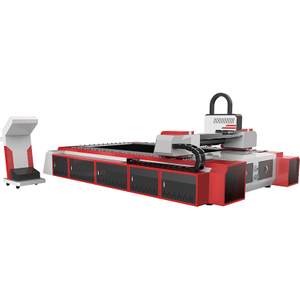

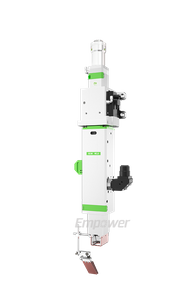

Exhibit introduction: S series 12000 watt single table cutting machine

● High rigidity machine bed, exclusive high-temperature CNC electric furnace standard annealing process annealing treatment, can ensure long-term stability of machine tool accuracy;

● Imported original packaged fiber laser, good beam quality, stable performance, no reflective lens, no need to adjust the optical path, basically maintenance-free, the service life can reach more than 100,000 hours;

● Fiber laser has high electro-optical conversion rate, conversion efficiency up to 30%, which can greatly save power consumption during work and extremely low operating cost;

● Fast cutting speed, extremely low operating cost, and quick return on investment.

It can cut a variety of metal sheets, mainly suitable for rapid cutting of stainless steel, carbon steel, galvanized sheet, electrolytic sheet, brass sheet, aluminum sheet, manganese steel, various alloy sheets, rare metals and other materials.

Laser welding machine

Exhibit Introduction: Handheld Laser Welding Machine

● General workers get started in 2 hours

● Efficiency 2~10 times No need for employment certificate

● No need to polish the welding surface

● Small thermal influence, no deformation

● Weld seam is smooth

● Modular control, safety is guaranteed

Laser descaling machine

Exhibit Introduction: Handheld Laser Rust Remover

● Use laser to remove contaminants on the surface of the object to be cleaned. Because laser has excellent coherence, directionality and brightness, it can produce at least three effects. Mainly used in sheet metal cabinet surface rust removal.

● Under the three functions, the laser has the ability to remove surface pollutants. Compared with other cleaning methods, the advantages of laser cleaning are: "green" environmental protection and low labor intensity.

● Vibration effect uses high-frequency laser to impact the surface of the object to be cleaned, and the beam rotates into sound waves and returns from the lower surface, interfering with the incident wave, resulting in resonance and fragmentation of contaminants; thermal expansion effect uses substrate and surface contaminants to The difference in the absorption coefficient of the laser energy of a certain wavelength causes the pollutant to absorb the laser energy and thermally expand in an instant, forming a large detachment acceleration, which overcomes the adsorption force of the substrate on the pollutant and falls off; the photolysis and phase change of the molecule can make the The pollutant molecules are instantly vaporized, decomposed and evaporated.

● Laser cleaning has the characteristics of no grinding, non-contact, no thermal effect and suitable for objects of various materials, and is considered to be the most reliable and effective solution. At the same time, laser cleaning can solve problems that cannot be solved by traditional cleaning methods.

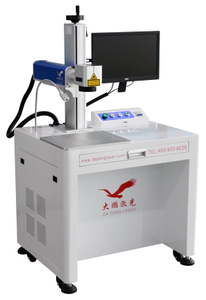

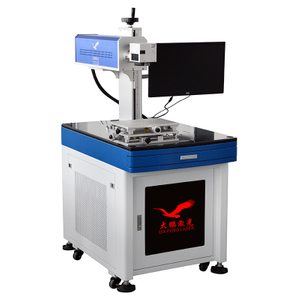

laser marking machine

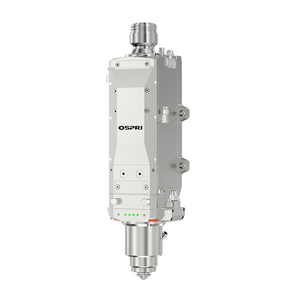

Exhibit introduction: FC laser marking machine

● Excellent beam quality;

● Maintenance-free operation, non-contact processing, high processing efficiency, computer control, easy to realize automation;

● Good stability, high pulse frequency, uniform engraving lines, fine patterns, and strong engraving depth capability.

Widely used in all metal products, integrated circuit chips, computer accessories, industrial bearings, clocks and watches, electronic and communication products, aerospace devices, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco and military purposes and many other fields Graphical and textual markers.