MK-400PLUS Carbide Insert Grinding Machine

Fully Automatic 5-Axis Complex Insert Peripheral Grinding Machine

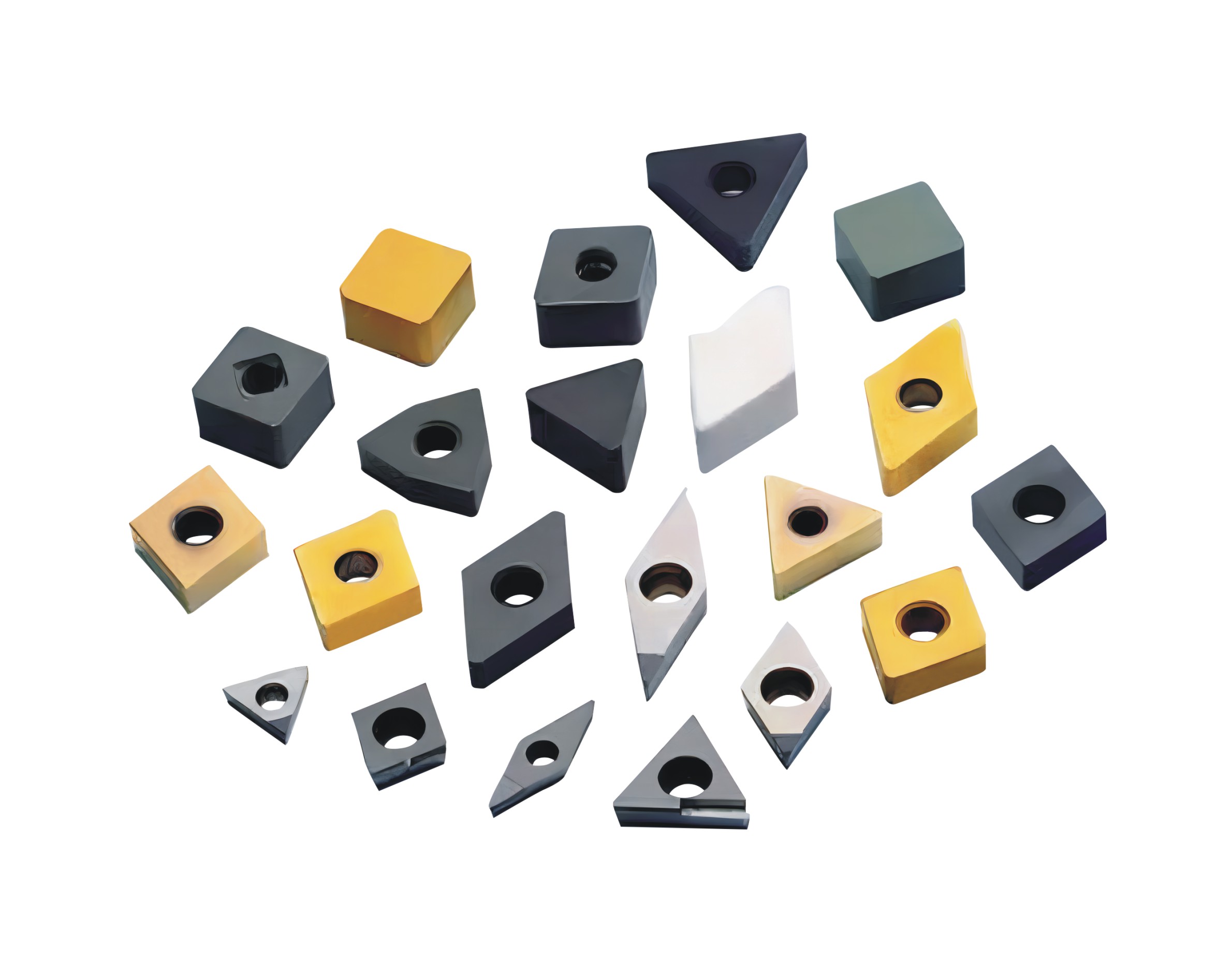

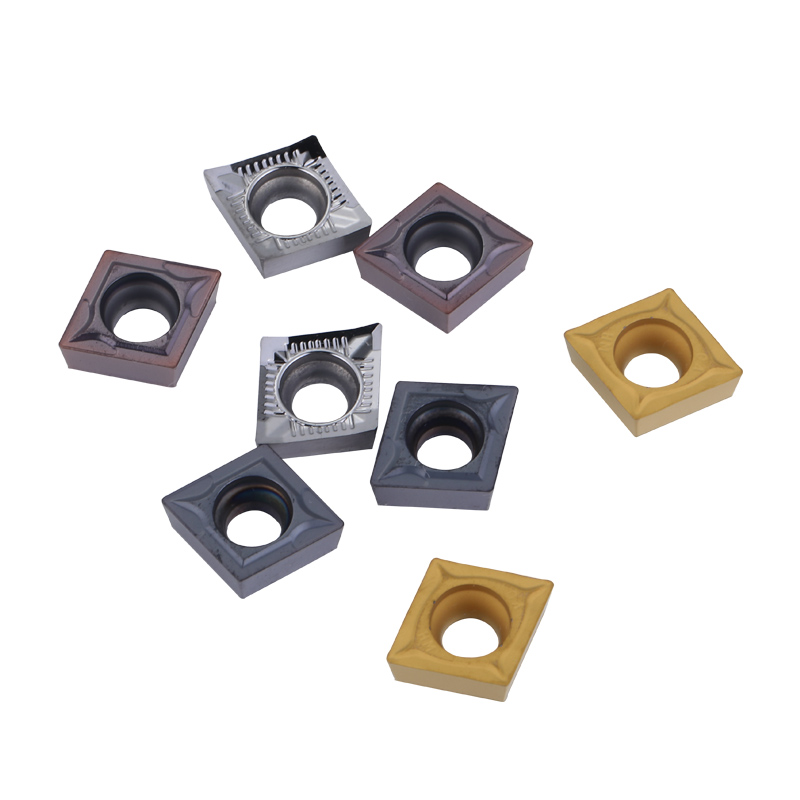

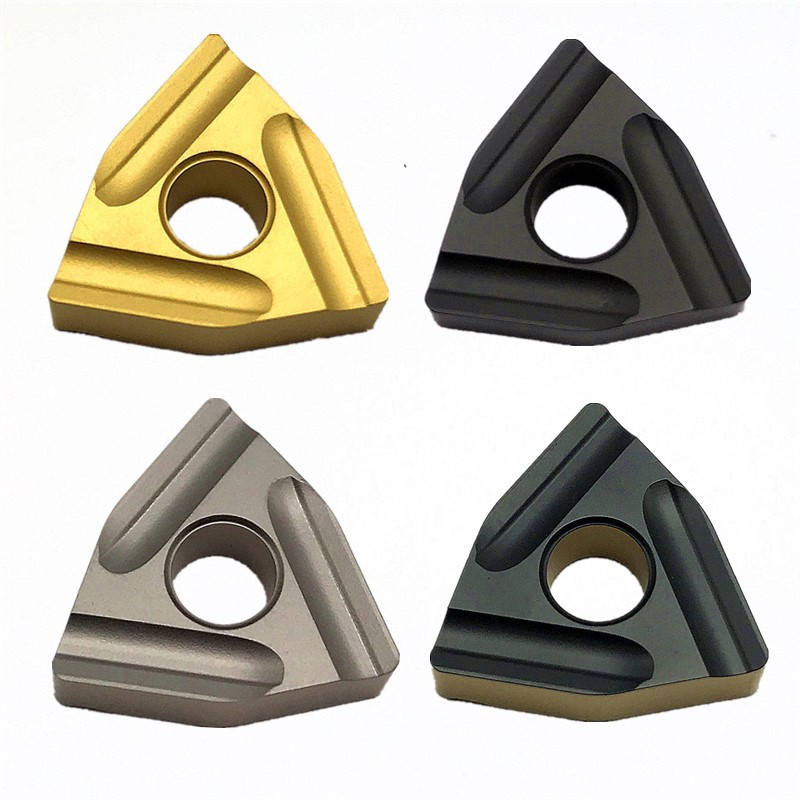

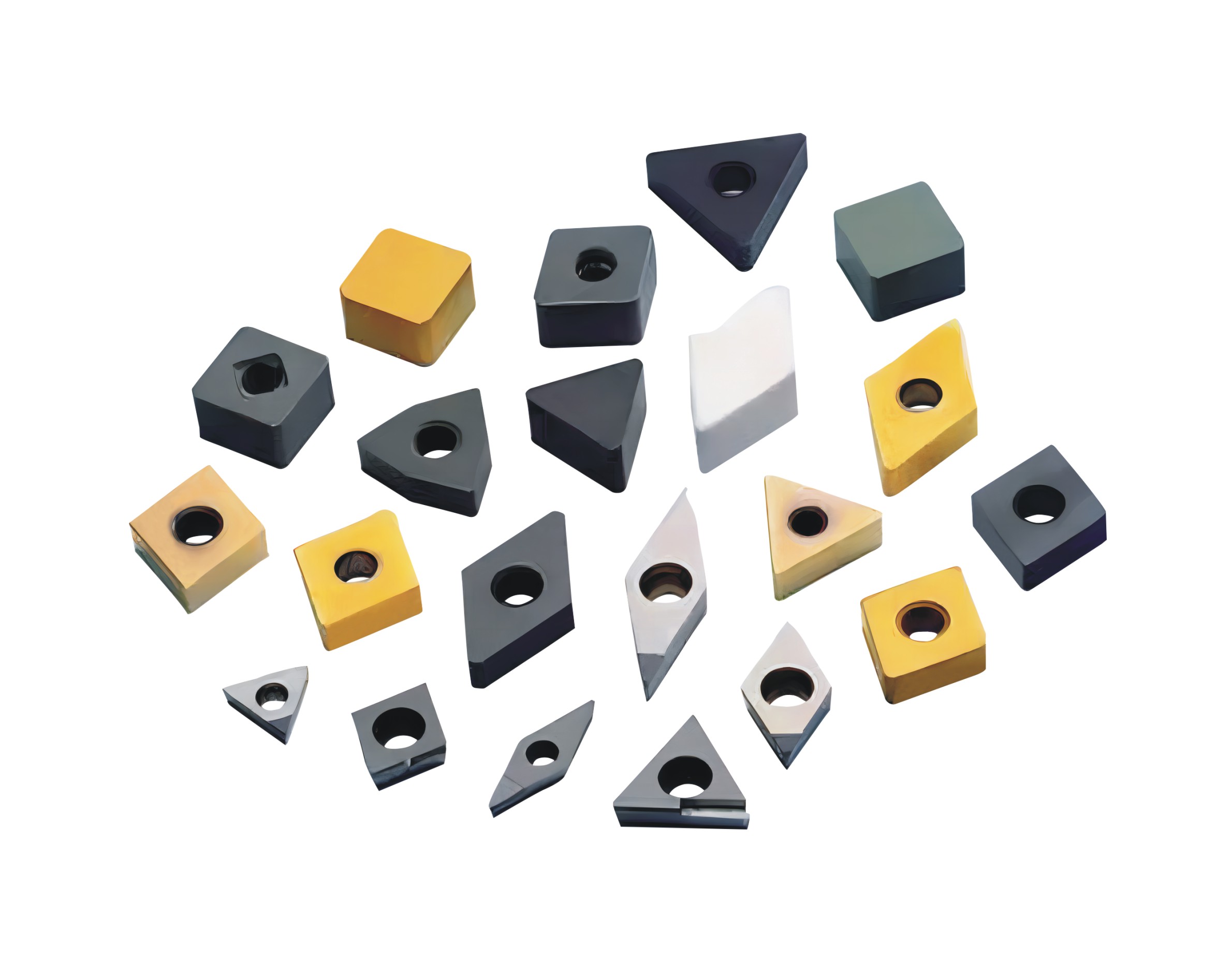

For Carbide, Cermet, Ceramic, CBN, and PCD Inserts

Product Overview

The MK-400PLUS is a cutting-edge, fully automatic 5-axis CNC insert grinding machine designed to meet the rigorous demands of modern cutting tool manufacturers. It specializes in peripheral grinding of indexable inserts with high precision and efficiency, handling superhard materials such as carbide, cermet, ceramic, cubic boron nitride (CBN), and polycrystalline diamond (PCD).

This versatile machine is engineered to perform peripheral and single-side land grinding of standard and complex inserts with minimal operator involvement, ensuring consistent product quality, enhanced throughput, and streamlined manufacturing workflows.

Technical Specifications

| Parameter | Specification |

| Minimum Inscribed Circle | 3.5 mm (Equilateral Triangle), 4.7 mm (Other Shapes) |

| Maximum Circumscribed Circle | 45 mm |

| Maximum Insert Thickness | 15 mm (Can process up to 3 pieces of 4.76 mm thickness simultaneously) |

| Main Spindle Motor | 7.5 kW, 3-phase induction motor, V3 insulation class |

| Grinding Wheel Dressing Motor | 1.5 kW electric spindle |

| Tailstock Maximum Clamping Pressure | 10 kN (at 7 MPa hydraulic pressure) |

| Machine Dimensions (W×D×H) | 2,475 × 2,250 × 2,160 mm |

| Machine Weight | 5,500 kg |

| Power Supply | 25 kVA, AC 380V (50/60 Hz) |

| Compressed Air Requirement | ≥0.5 MPa, 250 N/min |

| Hydraulic Pressure | Max 7 MPa |

Axis Configuration and Motion Control

X-axis: Left-right oscillation with centralized automatic lubrication

Y-axis: Feed movement with direct-drive technology and centralized lubrication

A-axis: Workpiece rotation with extended continuous swivel range (Blade seat projection length: 36 mm)

C-axis: Workpiece table angle adjustment from -91° to +91° (depending on grinding wheel and other conditions)

V-axis: Online grinding wheel cleaning system

W-axis: Blade core positioning with manual fine adjustment

Robotic Workpiece Handling: 3-axis linear robotic arm for tray loading/unloading, including B1, B2, B3 axes for transport and lifting

Maximum simultaneous CNC control over 9 axes enables complex, multi-dimensional grinding strategies.

Core Features and Advantages

Fully Automated Grinding Process

The MK-400PLUS provides one-clamping peripheral and land grinding for indexable inserts, eliminating time-consuming multiple setups. The integration of a robotic loading/unloading system automates part handling for uninterrupted, high-volume production.

Superior Precision and Rigidity

Constructed on a robust, high-rigidity frame, the machine maintains micron-level accuracy and exceptional surface finish throughout extended grinding cycles. Mechanical stability minimizes vibration and thermal drift, ensuring consistent and repeatable results.

Intelligent Measurement and Quality Control

Equipped with a sophisticated measurement system, the MK-400PLUS performs:

Pre-process dimensional verification

Post-process inscribed circle inspection

Automated rejection of defective inserts and rework logic

Automatic compensation for subsequent inserts to maintain tight tolerances

Optional 3D measuring probe for enhanced geometric analysis

Grinding Wheel Dressing and Blade Positioning

The dressing system, powered by a 1.5 kW electric spindle, allows precise side and profile dressing of grinding wheels, ensuring sharp cutting edges and uniform finishes. Blade positioning can be manually fine-tuned for perfect centering and alignment.

User-Friendly Software and Integration

The machine supports Agathon’s ToolLab software for simple and advanced programming capabilities. Whether for novice users or expert programmers, the software provides:

Guided workflows and preset templates for quick setup

Full control over 5-axis CNC toolpaths

Compatibility with the Evo platform’s hardware and tooling

Easy transition from other grinding systems

Design and Safety

CE-compliant, fully enclosed work area for operator safety

Centralized automatic lubrication for reduced maintenance

Compact footprint optimized for modern production floors

Energy-efficient design reduces operational costs

Intuitive HMI interface facilitates smooth operation and diagnostics

Application Range

The MK-400PLUS excels in grinding a wide variety of inserts for:

Carbide and Cermet tools used in general machining

Ceramic and CBN tools for high-speed and precision applications

PCD tools for abrasive materials such as composites and non-ferrous metals

Complex geometries with multiple cutting edges, chipbreakers, and special contours

Large batch production as well as flexible small batch jobs

Ideal Customers

Indexable insert manufacturers aiming to automate and scale production

Toolmakers requiring superior grinding precision and process repeatability

High-mix manufacturers needing flexible 5-axis grinding solutions

Companies integrating robotic automation for lights-out manufacturing

Summary

The MK-400PLUS represents the pinnacle of insert grinding technology, delivering fully automated, multi-axis grinding solutions tailored for the highest precision and throughput requirements. Its powerful combination of mechanical rigidity, intelligent measurement, and software integration makes it a critical asset for any cutting tool production operation seeking to enhance quality and efficiency.