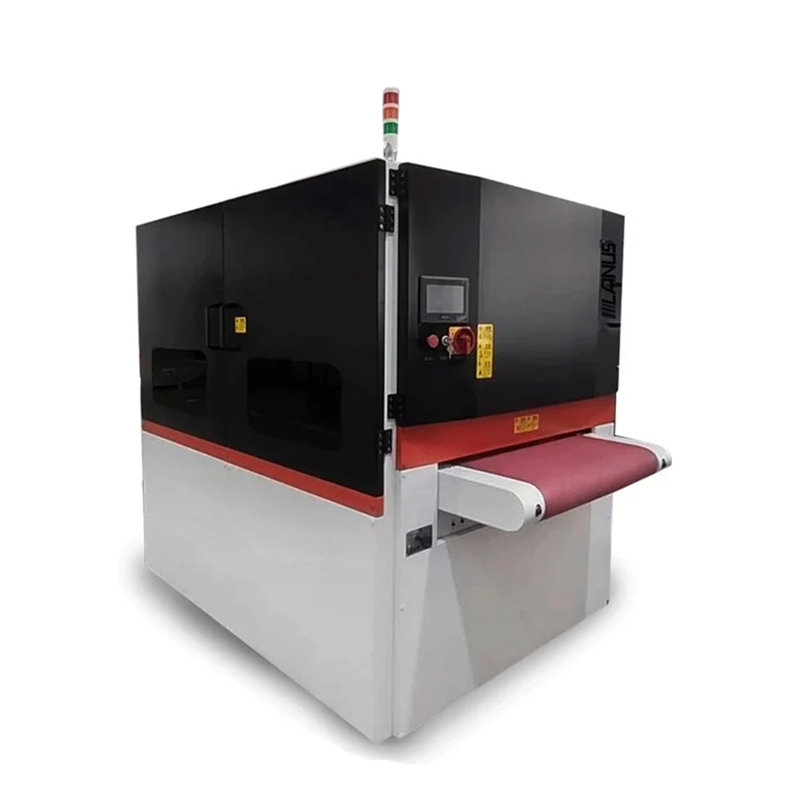

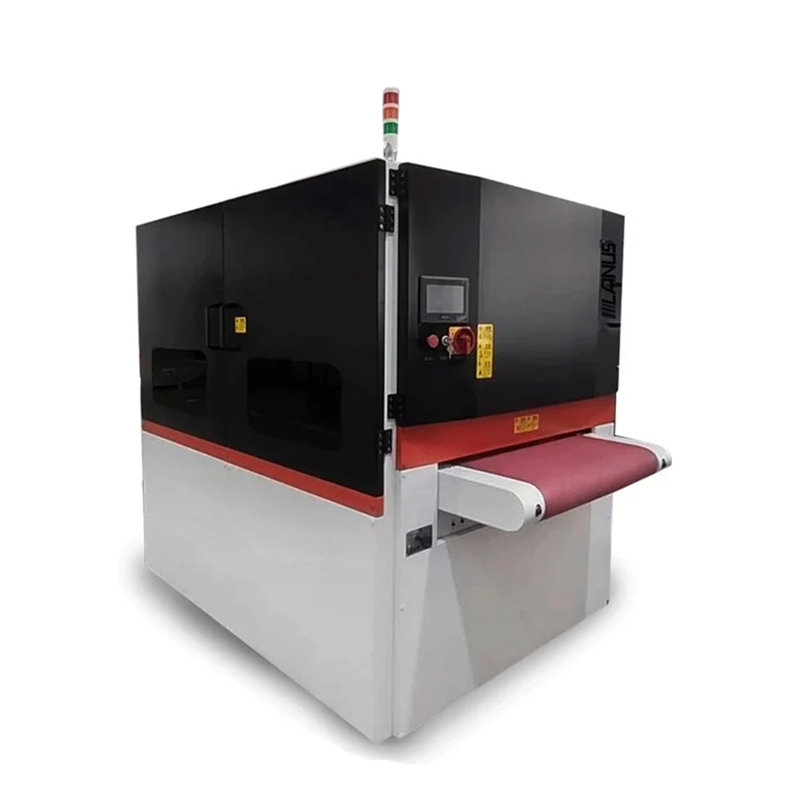

MSP-L800 Metal Finishing and Deburring Machine

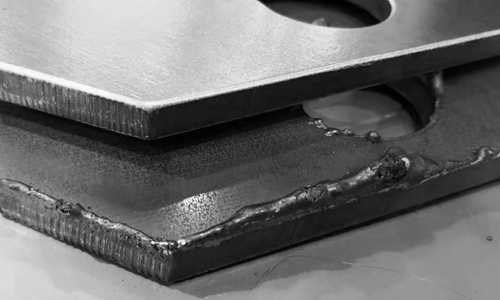

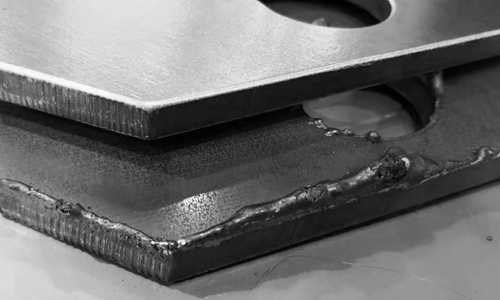

The MSP-L800 is a highly versatile and advanced deburring, edge rounding, and finishing machine designed to meet the demands of high-quality metal processing. This machine combines innovative features and efficient design to provide uniform, high-precision results on a variety of materials, including stainless steel, carbon steel, aluminum, copper, and other metals commonly used in sheet metal fabrication. It is specifically tailored for post-processing applications like laser cutting, punching, plasma cutting, and shearing, offering significant advantages in deburring, oxide removal, and surface finishing.

Key Features of the MSP-L800

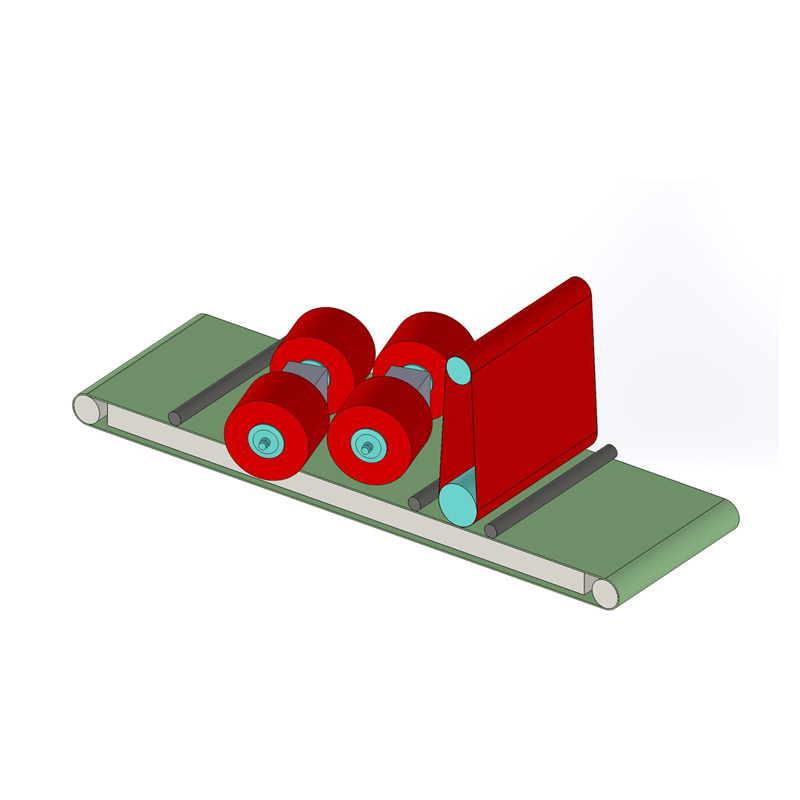

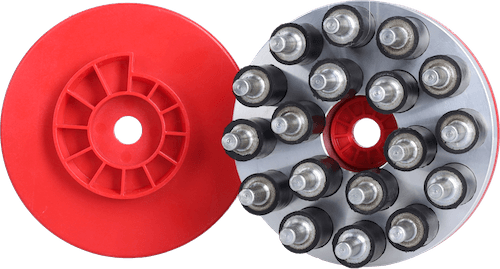

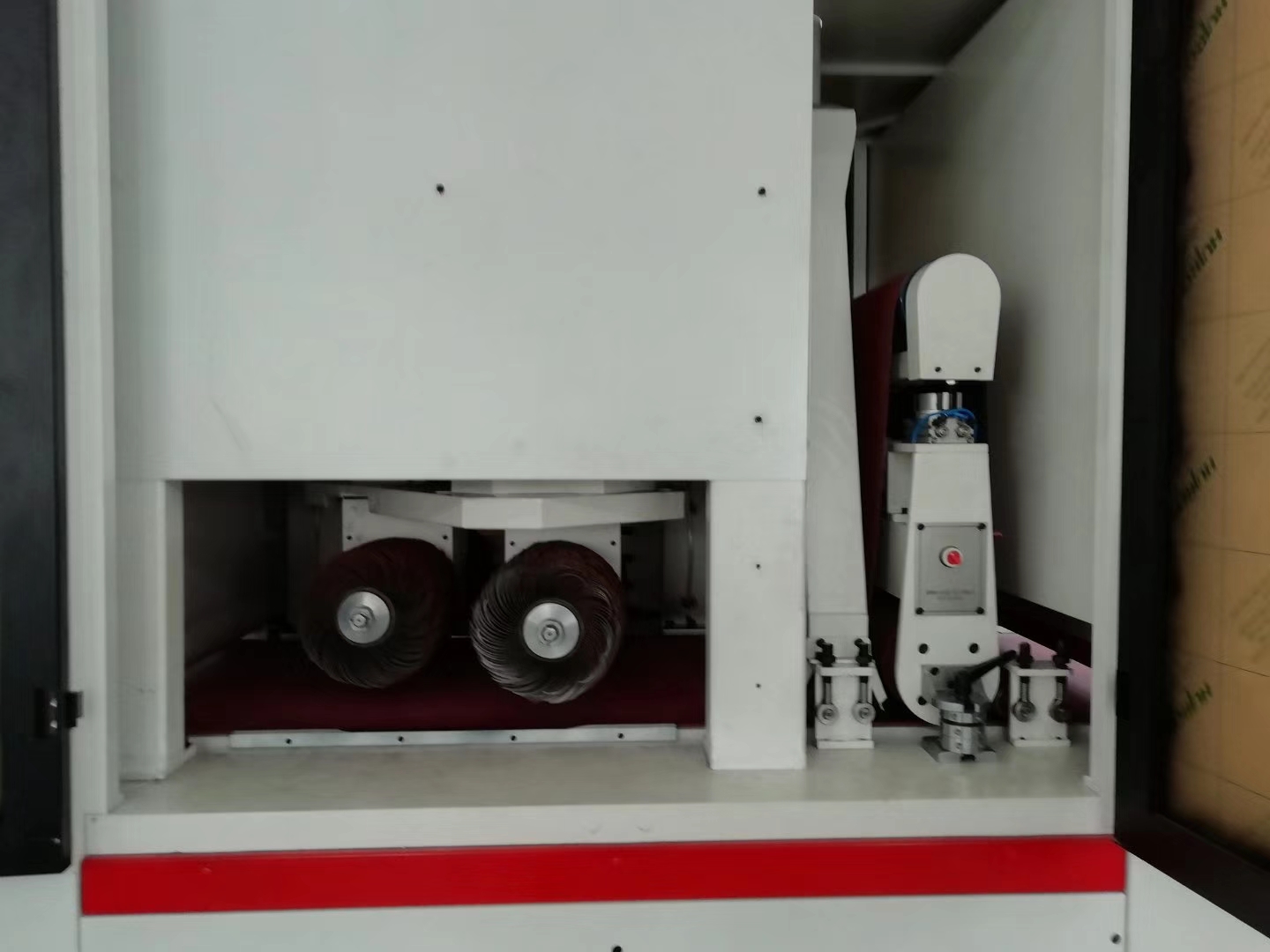

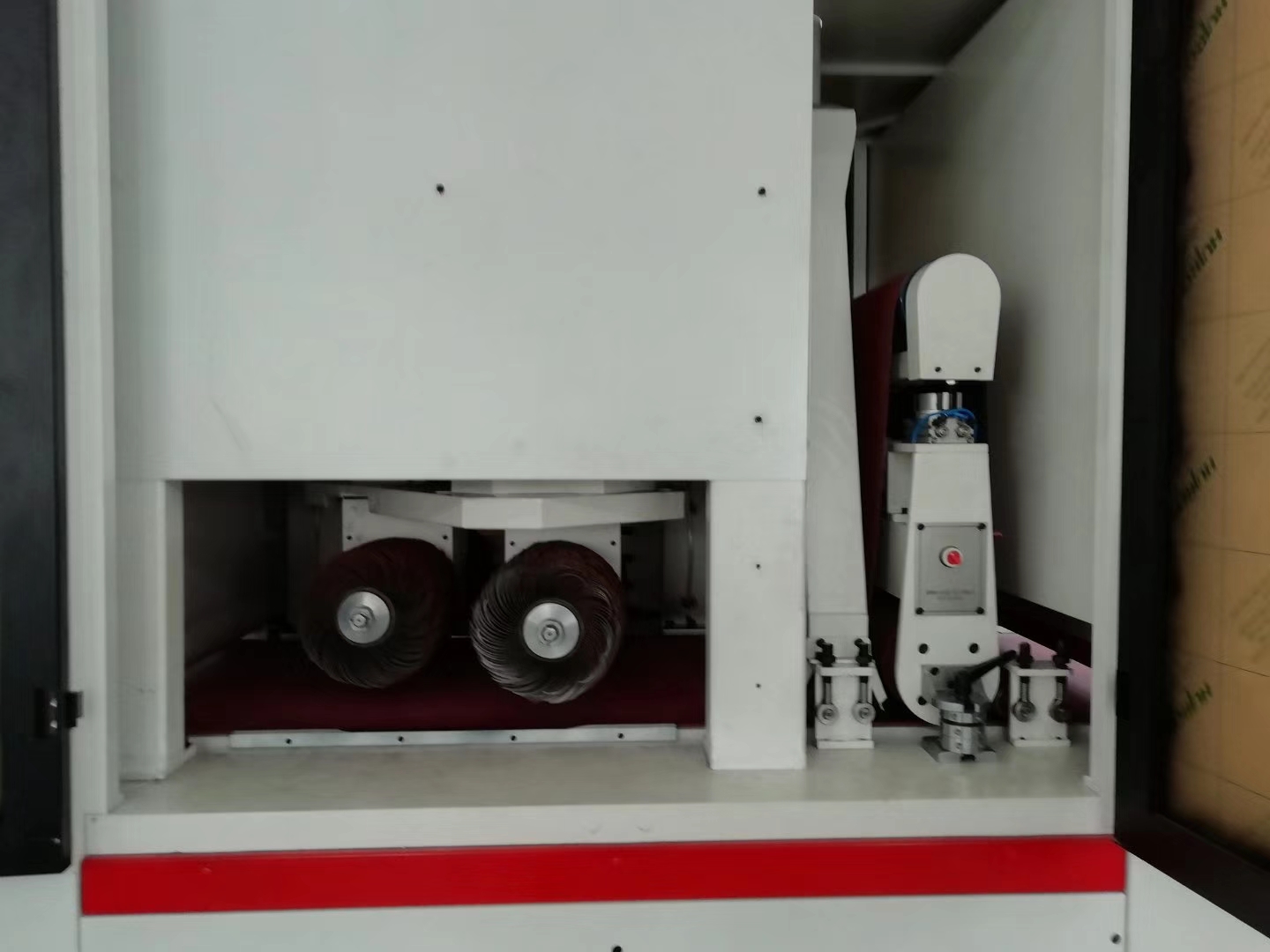

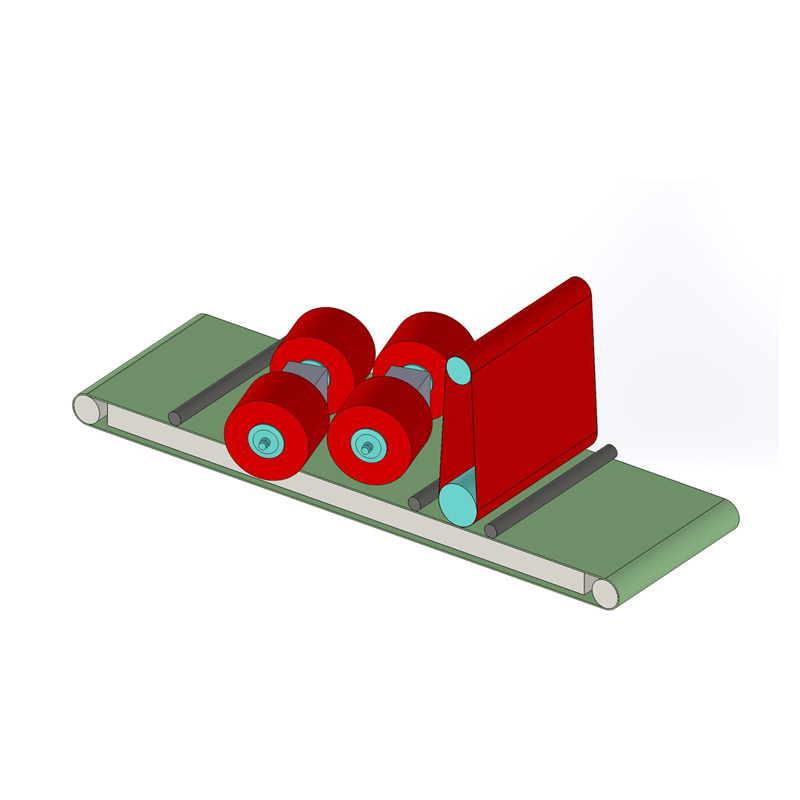

Rotary Brush Head with Counter-Rotating Brushes

At the heart of the MSP-L800’s functionality is its rotary brush head, which features eight counter-rotating brushes mounted on a single head. This head rotates around a vertical axis while simultaneously oscillating across the workpiece. The combination of rotation and oscillation allows for uniform, 360° edge rounding from all angles, ensuring that edges are rounded evenly and consistently. This innovative technology can achieve edge rounding up to a radius of 2 mm, which is ideal for parts with sharp edges or burrs from cutting processes.

Versatile Processing Configurations

The MSP-L800 offers multiple configurations to suit different processing needs:

Deburring + Edge Rounding + Finishing

Deburring + Edge Rounding + Oxide Removal

Grinding + Finishing

This versatility allows manufacturers to select the best configuration for specific applications, optimizing for either deburring, surface finishing, oxide removal, or a combination of these processes.

Floating Abrasive Belt Station

The machine can be equipped with an abrasive belt station in front of and/or behind the rotary brush head. This unit features Loewer's floating head system, which allows the abrasive belt to shift away if excessive grinding pressure is applied. This protects the contact drum and prevents workpieces from overheating, enhancing both the quality of the finish and the longevity of the machine components.

Adjustable Brush Settings

The four outside brushes on the rotary head can be independently adjusted in terms of height and revolutions per minute (rpm), allowing the operator to fine-tune the machine for different materials or processing requirements. For example, two distinct brush types can be used simultaneously—such as lamella brushes for edge rounding and wire brushes for oxide removal—enhancing the machine's flexibility and application range.

Conveyor System with Magnetic Track

The MSP-L800 uses a powerful magnetic track beneath the conveyor belt to securely hold down smaller steel parts during processing. This magnetic system allows for easy, tool-free processing of small and medium-sized workpieces, providing consistent results without the need for specialized fixtures or workholding devices.

Efficient Dust Extraction System

Dust collection is a crucial feature of any industrial finishing machine, and the MSP-L800 is equipped with a highly efficient dust extraction system. This system ensures that harmful abrasive dust is collected and filtered, providing a cleaner working environment and improving operator safety. The dust extraction system is designed to handle the dust generated by both dry and wet processing methods, and the extracted air is filtered and returned clean to the atmosphere.

Compact and Ergonomic Design

Despite its advanced capabilities, the MSP-L800 is designed with a compact footprint. The rotary brush head requires only 800 mm of length, making it ideal for spaces where machine size is a concern. Its efficient design ensures that the machine requires less space while still providing highly effective processing capabilities. Additionally, the integrated vacuum system helps to keep small parts securely in place, improving efficiency and reducing the need for additional fixtures.

Advantages of the MSP-L800

Uniform, 360° Edge Rounding

The rotary brush head ensures that the entire edge of the workpiece, including internal and external contours, is processed evenly from all directions. The machine can round edges up to a radius of 2 mm, achieving consistent and smooth results without leaving any sharp edges or burrs.

Even Brush Wear and Long-Lasting Performance

The oscillating motion of the brushes and the independent adjustment of the outer and inner brushes ensure even wear over time. This results in consistent processing quality and extended brush life, making the MSP-L800 a highly cost-effective solution for long-term operations.

Minimal Heat Generation

One of the key features of the MSP-L800 is its ability to process parts without generating excessive heat, making it particularly suitable for foil-coated or zinc-coated sheet metals, which can be sensitive to high temperatures. The low heat generation prevents any damage to delicate coatings and maintains the integrity of the metal surface.

Versatility in Material Handling

The MSP-L800 is capable of processing a wide range of materials, including stainless steel, mild steel, aluminum, copper, and other metals. This makes it ideal for manufacturers working with diverse product types or in industries where multi-material processing is required.

Consistent, High-Quality Finishes

The combination of abrasive belt units and rotary brushes ensures that the machine delivers consistent, high-quality finishes on workpieces. The abrasive belt can be used for tasks such as graining (to achieve a decorative straight-line finish) or deburring, while the rotary brushes provide oxide removal and edge rounding.

Operator-Friendly Control System

The MSP-L800 is equipped with a touch panel control system, allowing operators to easily adjust key parameters such as feed speed, brush rpm, abrasive belt penetration, and more. The system also enables the storage of different machine programs, making it easier to switch between different processing tasks and maintain consistent results.

Technical Specifications

| Parameter | Specification |

| Processing Width | ≤800 mm |

| Processing Thickness | 0.5 ~ 80 mm |

| Minimum Workpiece Size | 50 mm × 50 mm (without holes) |

| Total Power Consumption | 30.25 kW (excluding dust extraction system) |

| Abrasive Belt Size | Φ1910 mm × 800 mm |

| Rotary Brush Size | Φ300 mm × 300 mm |

| Conveyor Speed | 0.5 ~ 6 m/min (adjustable via frequency inverter) |

| Abrasive Belt Line Speed | Approximately 18 m/s |

| Brush Self-Rotation Speed | 8 ~ 26 m/s (variable) |

| Brush Planetary Rotation Speed | 1 ~ 15 rpm (variable) |

| Thickness Adjustment Precision | 0.01 mm (servo-controlled) |

| Dust Extraction Air Volume | 4000 m³/h |

| Machine Dimensions | 2650 mm (L) × 1650 mm (W) × 2150 mm (H) |

| Machine Weight | Approximately 2.2 tons |

Conclusion

The MSP-L800 is a cutting-edge deburring, edge rounding, and surface finishing machine designed for optimal performance in metal processing. Its innovative features, including the rotary brush head, floating abrasive belt system, and adjustable parameters, provide manufacturers with a highly flexible and efficient solution for a variety of post-processing applications. With its robust design, versatile processing capabilities, and enhanced safety features, the MSP-L800 is an ideal choice for industries requiring high-quality surface finishes on metal components, from small sheet metal parts to larger, complex workpieces.