Typical applications: laser job shop, equipment manufacturing, electronics industry, aviation, automotive, precious metal processors, and custom applications

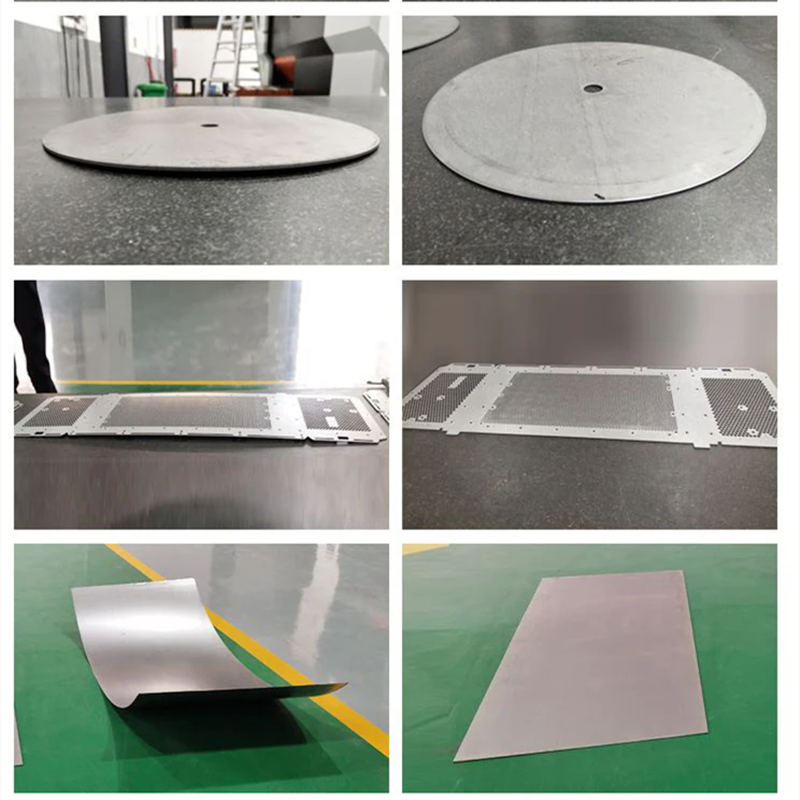

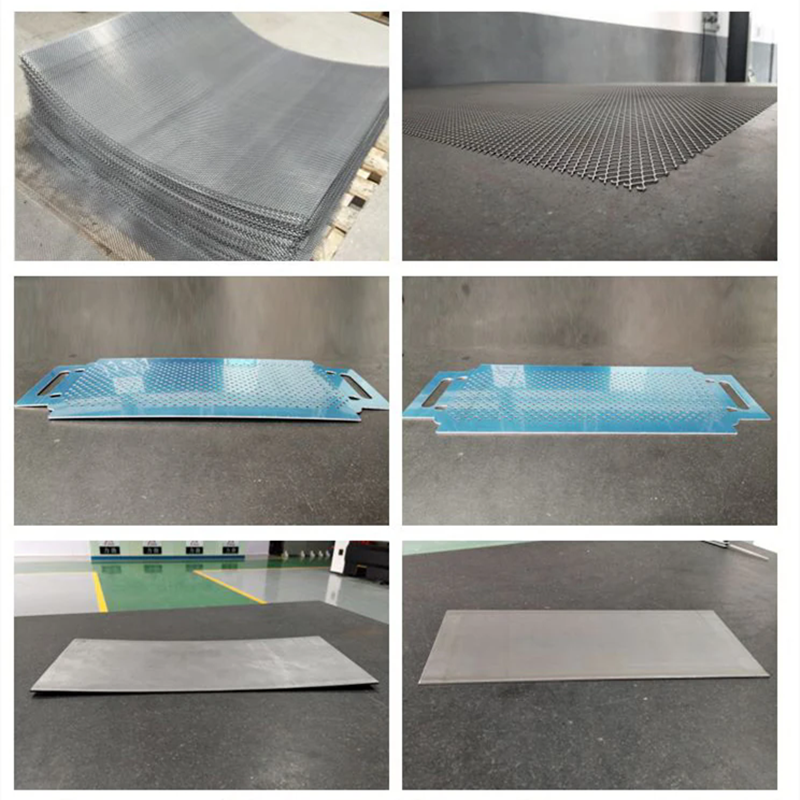

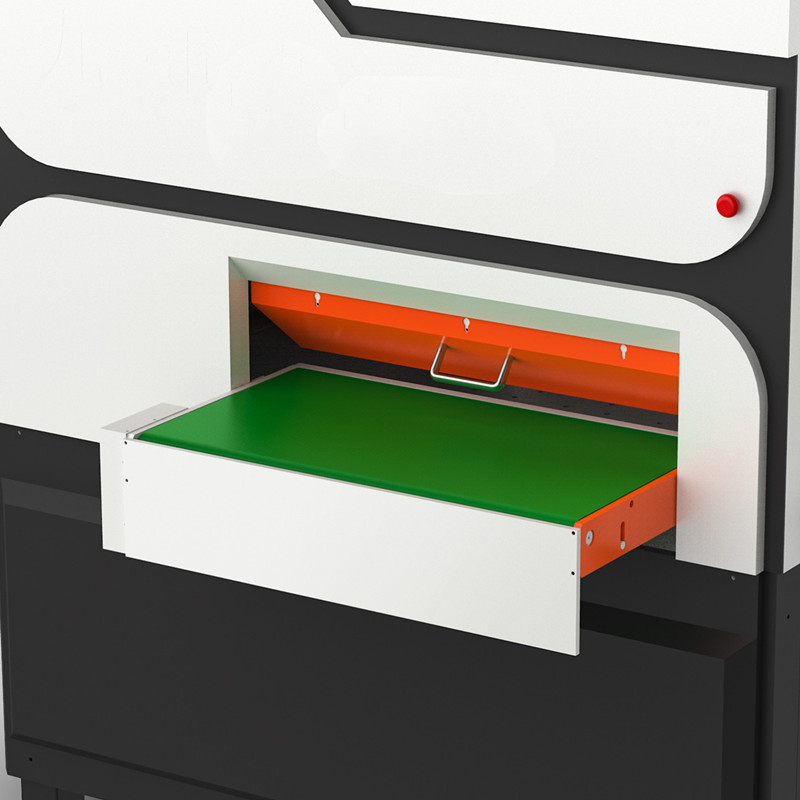

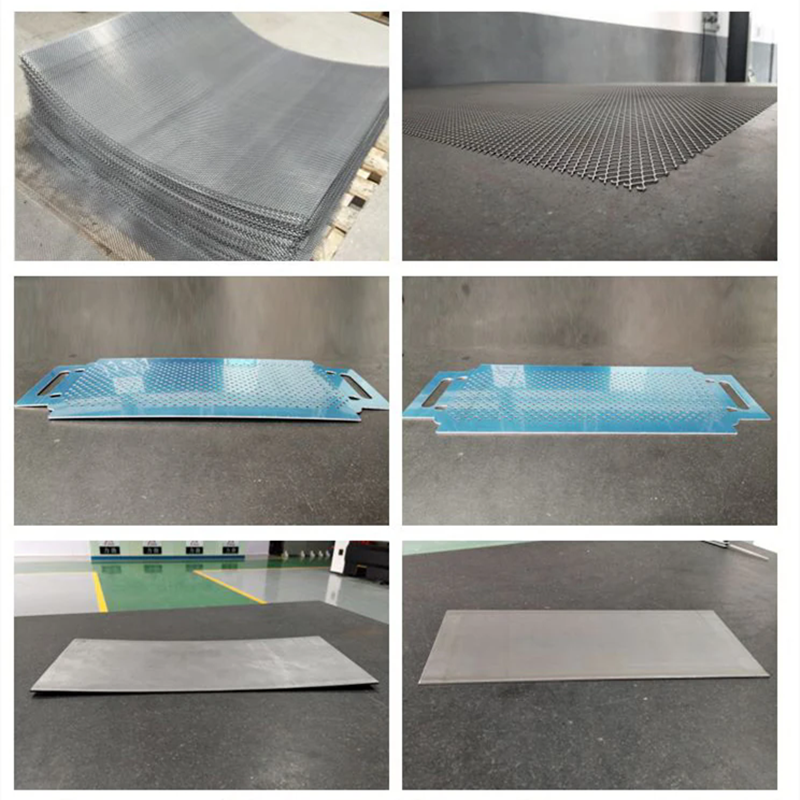

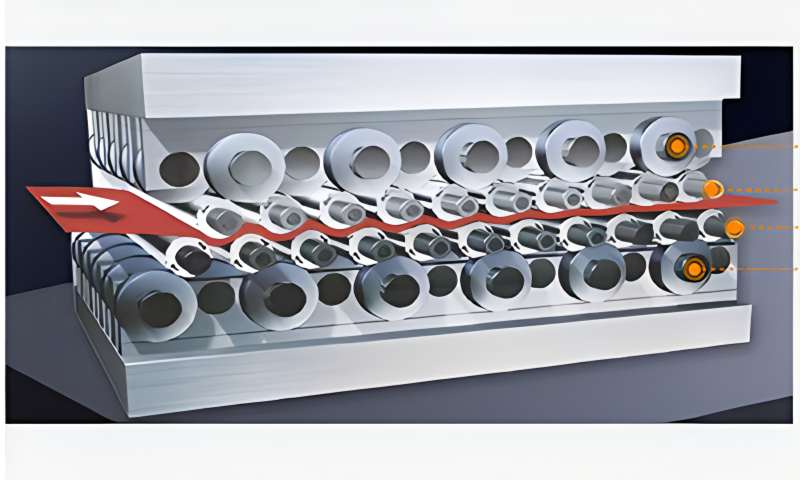

Precision leveling of small and medium-size parts. Excellent leveling results are achieved through the use of small leveling roller diameters, optimum roller spacing, and extra-wide supporting rollers.

For a leveling machine designed for precision leveling of small and medium-size parts in industries such as laser job shops, equipment manufacturing, electronics, aviation, automotive, and precious metal processing, here are some key features and applications that align with your requirements:

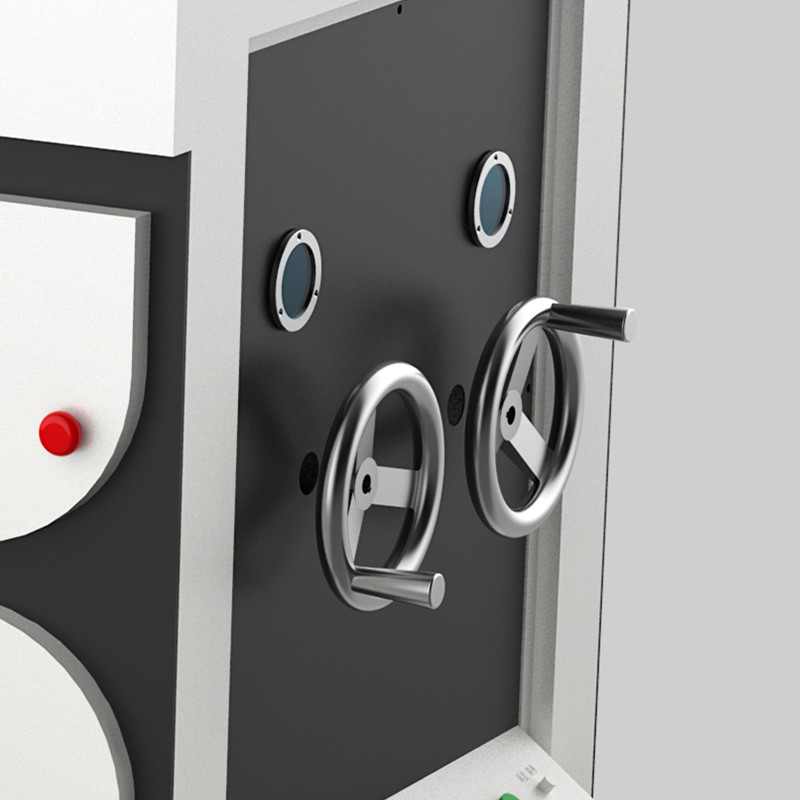

Key Features:

Precision Leveling:

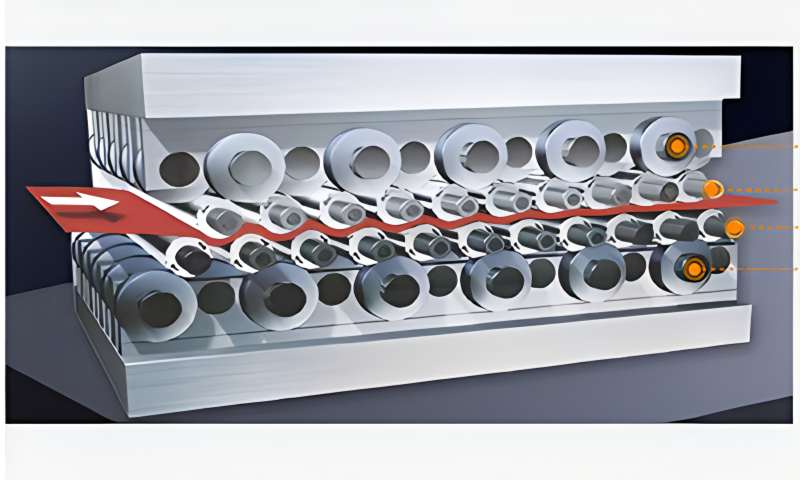

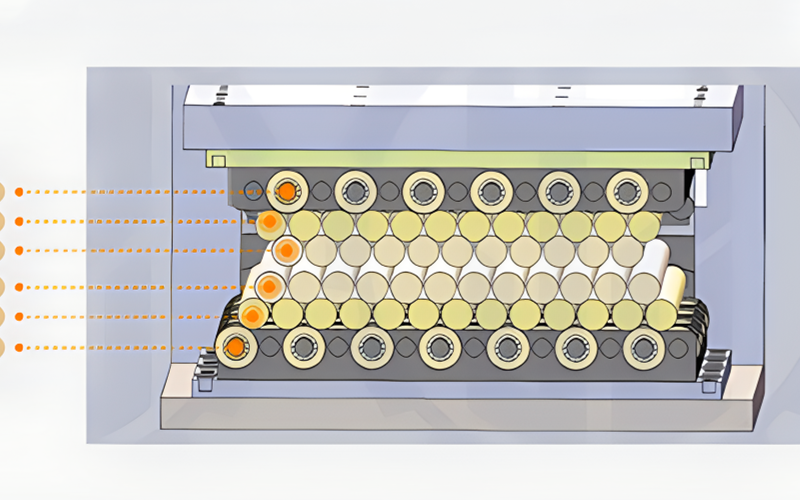

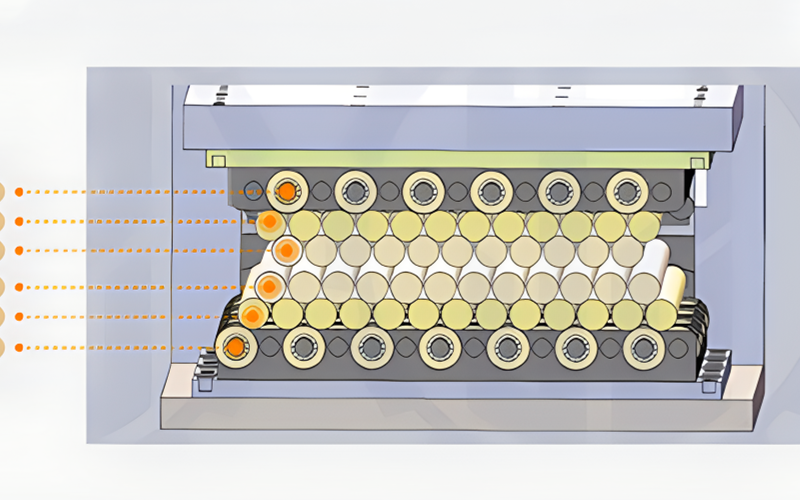

Small Roller Diameters: Enables precise leveling of small and medium-size parts, ensuring high accuracy and excellent surface quality.

Optimized Roller Spacing: The rollers are spaced optimally to provide uniform pressure across the entire sheet, minimizing distortions and achieving a flat, even surface.

Extra-Wide Supporting Rollers: These ensure the material is well-supported during processing, reducing the risk of deflection or bending, especially for thin sheets.

Processing Range:

Thickness: Capable of handling metal sheets with a thickness range of 0.8 mm to 3.5 mm.

Width: Suitable for sheets with a width of 400 mm to 800 mm, making it versatile for a range of small to medium-sized parts.

Material Compatibility:

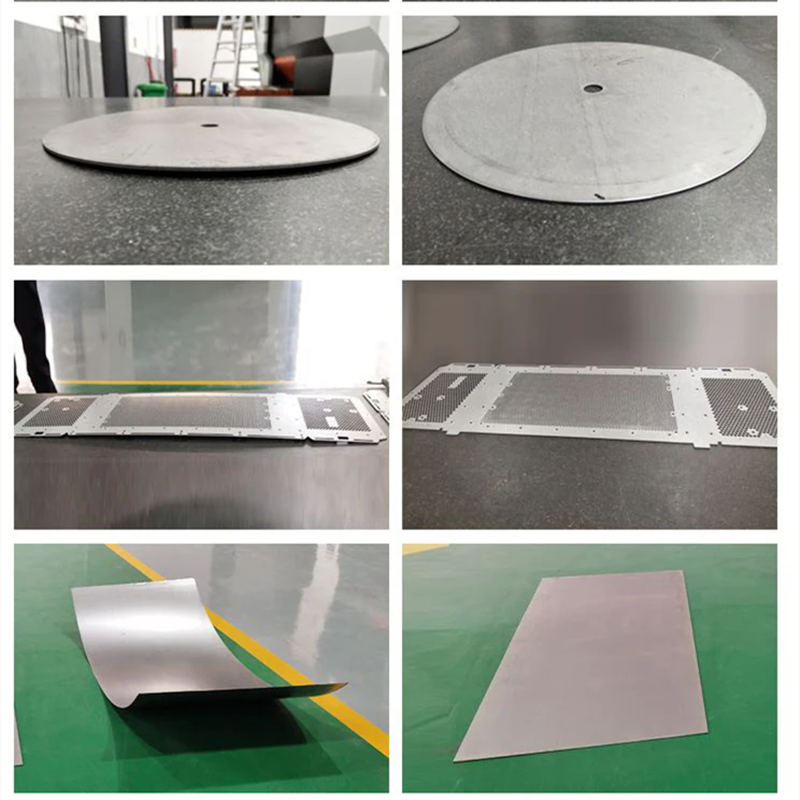

Carbon Steel, Stainless Steel, Aluminum, and Precious Metals: The machine is designed to handle a variety of materials, ensuring high-quality results across different metals.

Applications:

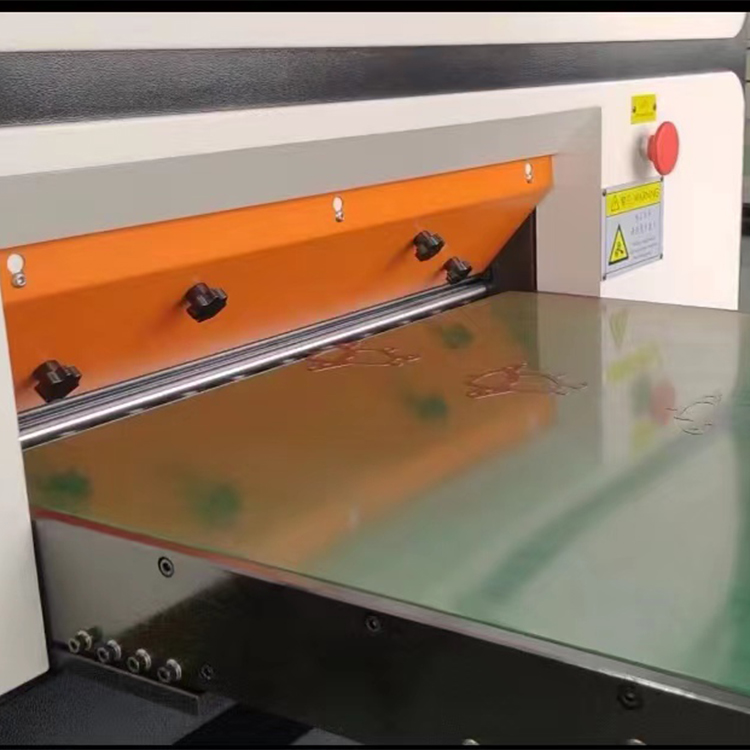

Laser Job Shops: Ideal for leveling parts that have been cut by laser, ensuring flatness and readiness for further processing.

Equipment Manufacturing: Ensures precise leveling of components used in machinery and equipment.

Electronics Industry: Prepares thin metal sheets for electronic components and housings.

Aviation and Automotive: Provides the precision needed for components used in these high-demand industries.

Precious Metal Processors: Ensures high-quality surface finishes for precious metal parts.

Custom Applications: Suitable for industries requiring tailored solutions for specific metal processing needs.

Advanced Control Systems:

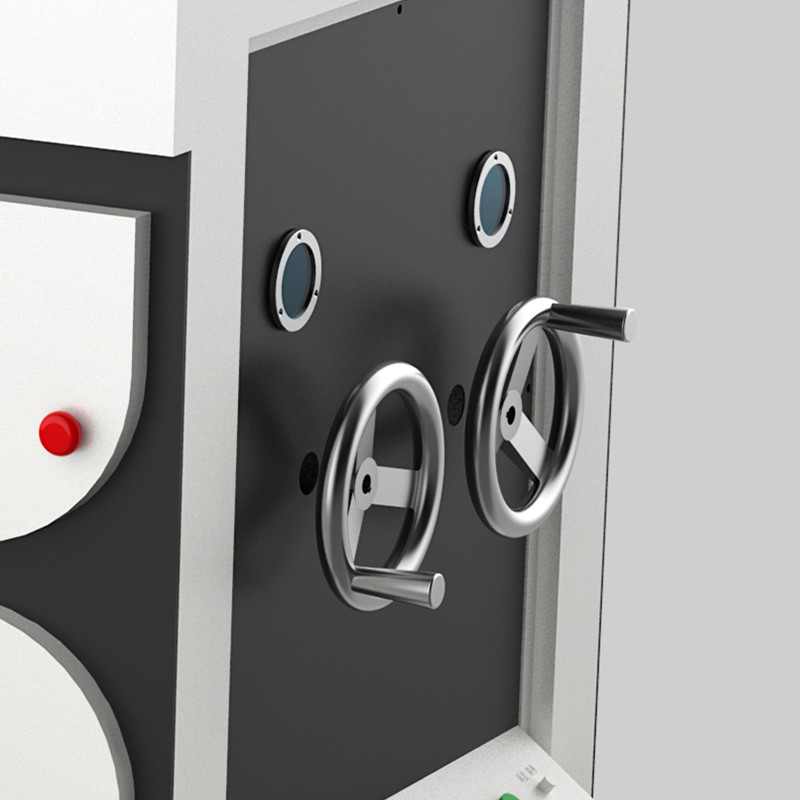

Servo-Controlled Adjustments: Allows for precise control of roller gaps, ensuring consistent results across different batches.

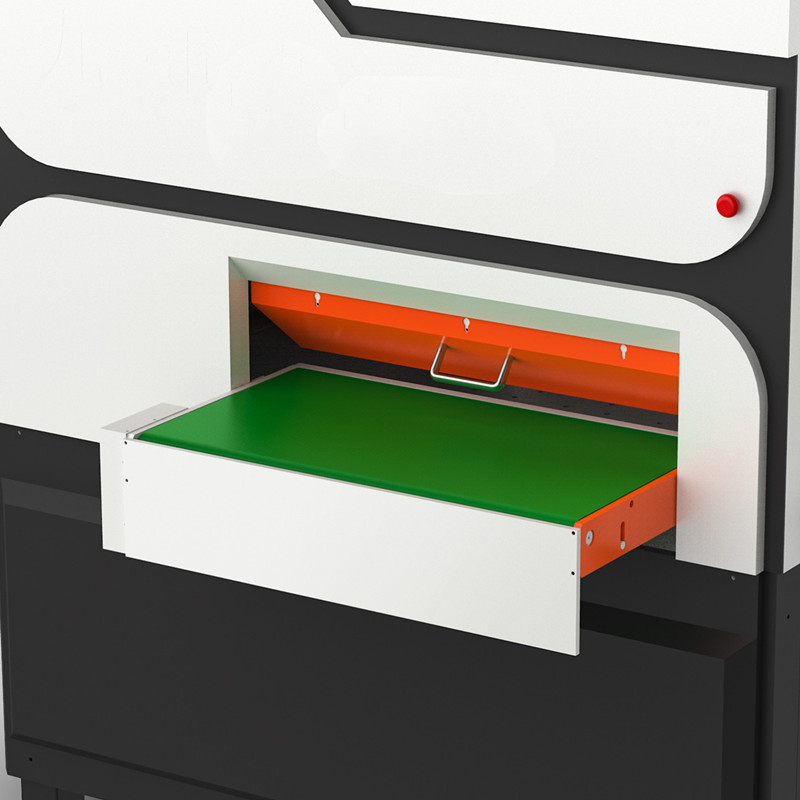

User-Friendly Interface: Digital control panel with preset options for different materials and thicknesses.

Robust Design:

Example Specifications:

Processing Thickness: 0.8-3.5 mm

Processing Width: 400-800 mm

Roller Diameter: Small diameter rollers for precision leveling

Roller Spacing: Optimized for even pressure distribution

Support Rollers: Extra-wide for better material handling

Material: Compatible with various metals, including carbon steel, stainless steel, aluminum, and precious metals

Benefits:

High Precision: Achieves excellent leveling results with minimal deviation.

Versatility: Suitable for a wide range of industries and applications.

Efficiency: Reduces manual intervention, increasing productivity.

Quality: Ensures consistent, high-quality results across different materials and thicknesses.

This machine is ideal for industries that require high precision and quality in leveling small to medium-sized metal parts. Whether for mass production or custom applications, it ensures reliable and consistent results.