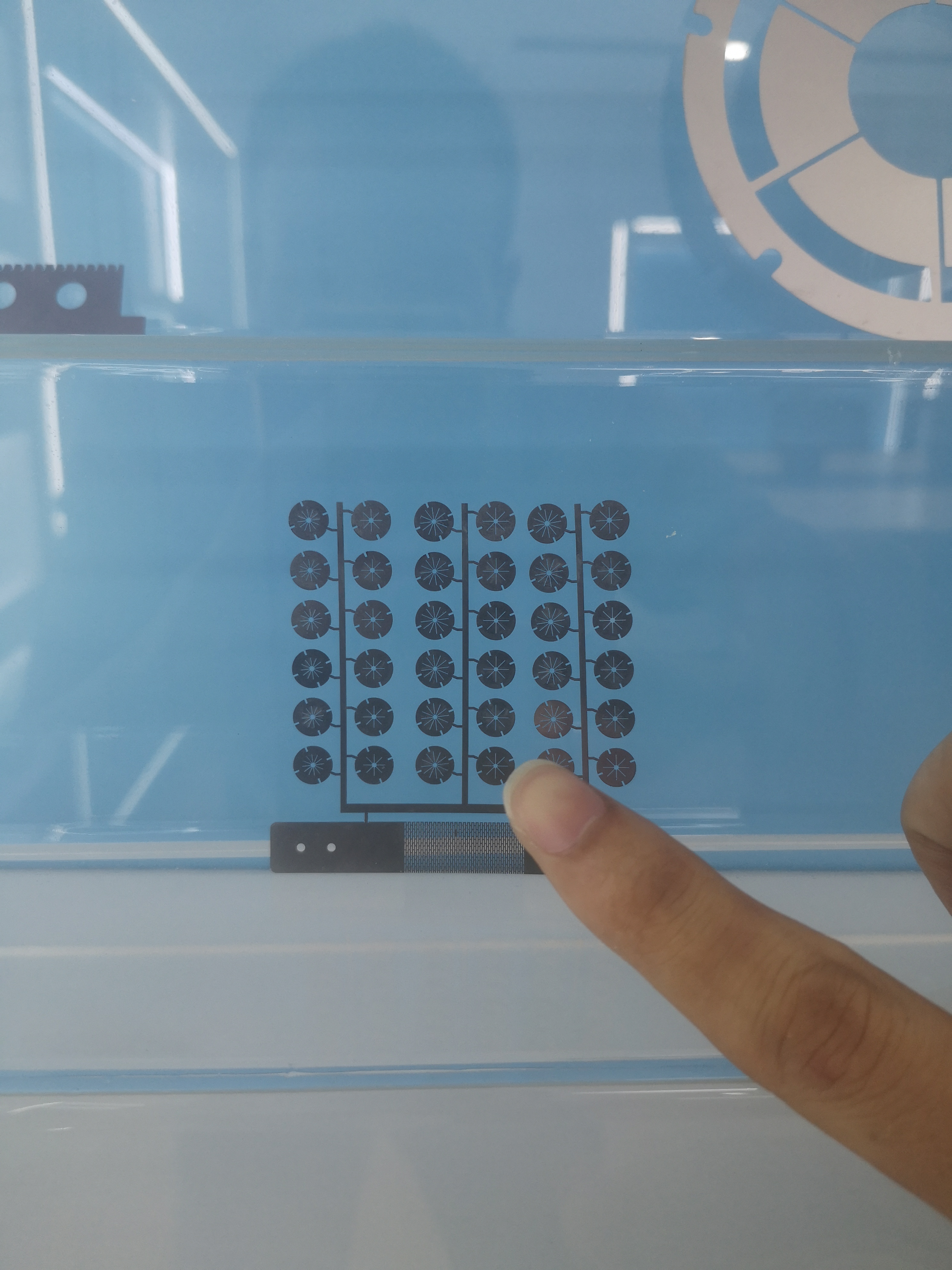

Protecting SMT Components: Selective solder fixtures are engineered to prevent soldering damage to the sensitive SMT components, ensuring precise solder joint formation for through-hole parts while maintaining the integrity of the SMT components.

Thermal Protection: These fixtures provide thermal shielding to protect heat-sensitive areas of the PCB during the selective soldering process, reducing the risk of thermal damage.

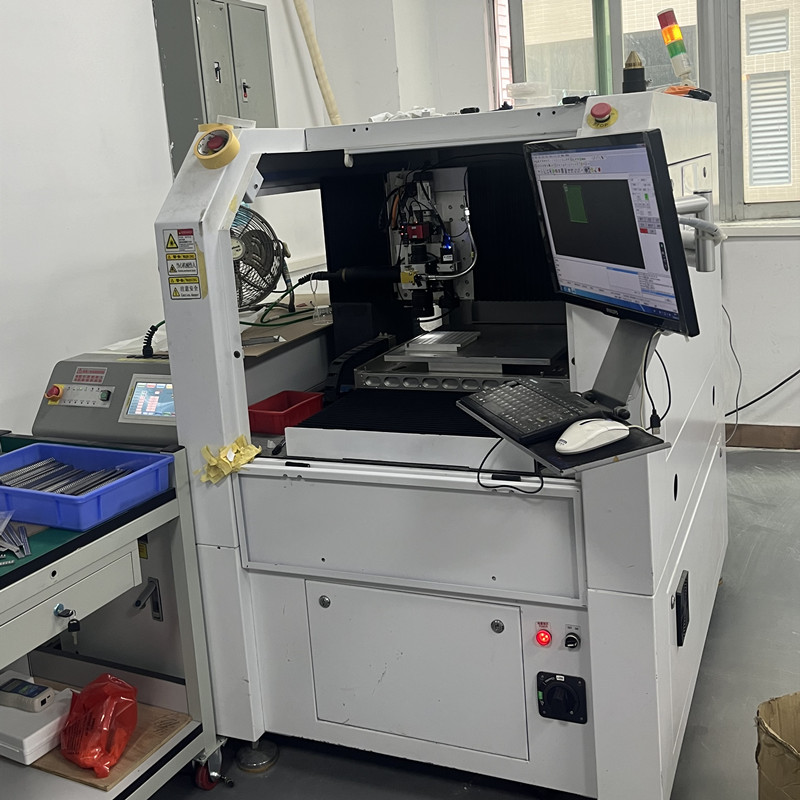

Custom Design for Specific Assemblies: Laser cutting technology allows for high-precision, custom fixtures tailored to the specific shape, size, and configuration of the PCB, ensuring perfect compatibility with the selective soldering system.

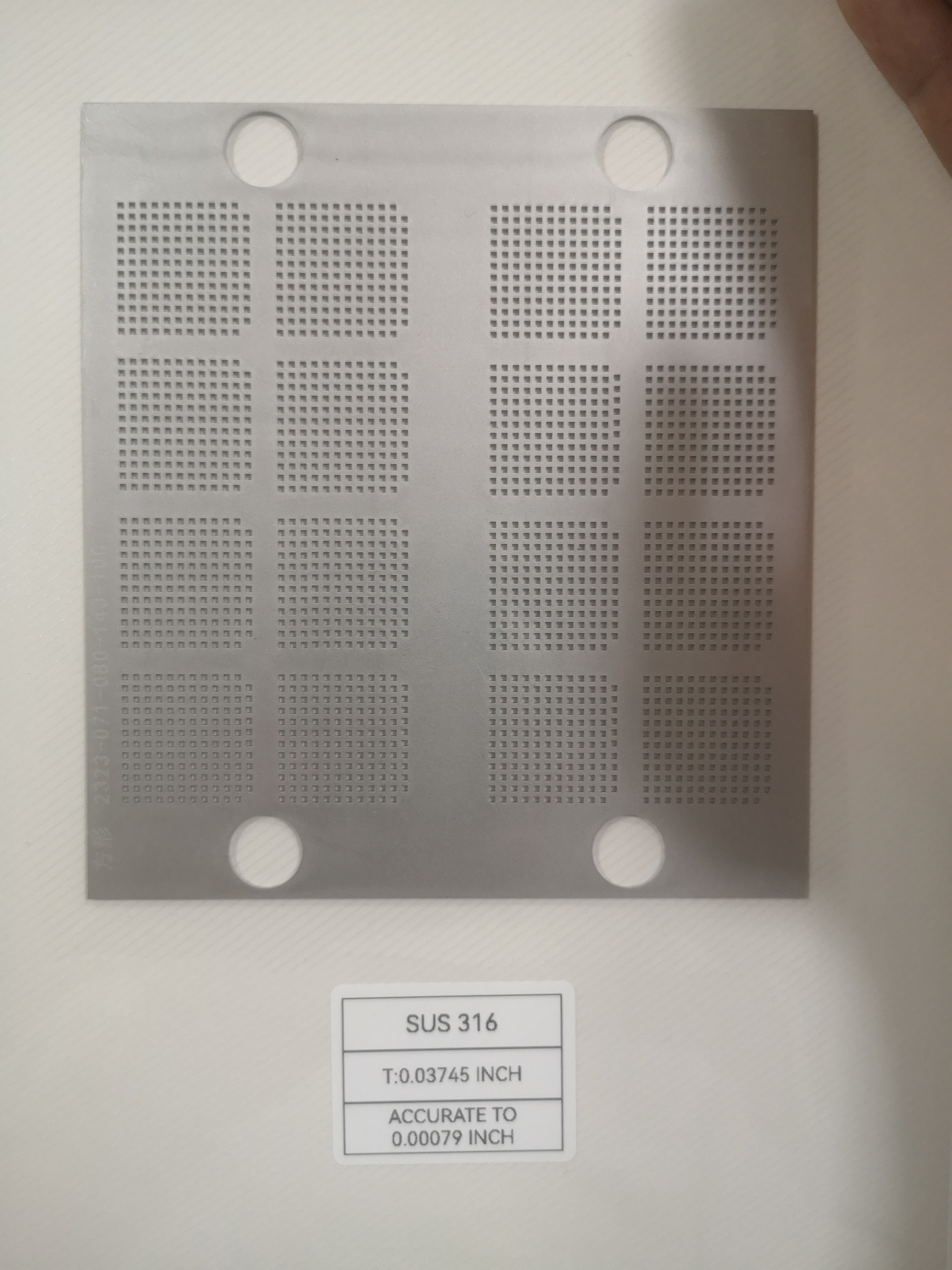

High Precision: Laser-cut fixtures offer ultra-precision, ensuring that components are held securely in place during the soldering process and guaranteeing consistent soldering quality.

Durable Materials: Fixtures are typically made from durable materials such as stainless steel or other heat-resistant metals to withstand high temperatures and mechanical stress during the soldering process.

Efficiency: By using selective solder fixtures, the assembly process is made faster and more efficient, as components are accurately aligned and securely held during the soldering, reducing the risk of errors and defects.

Cost-effective and Quick Turnaround: With laser cutting technology, fixtures can be produced with no tooling costs, providing a cost-effective solution with a fast lead time for custom designs.