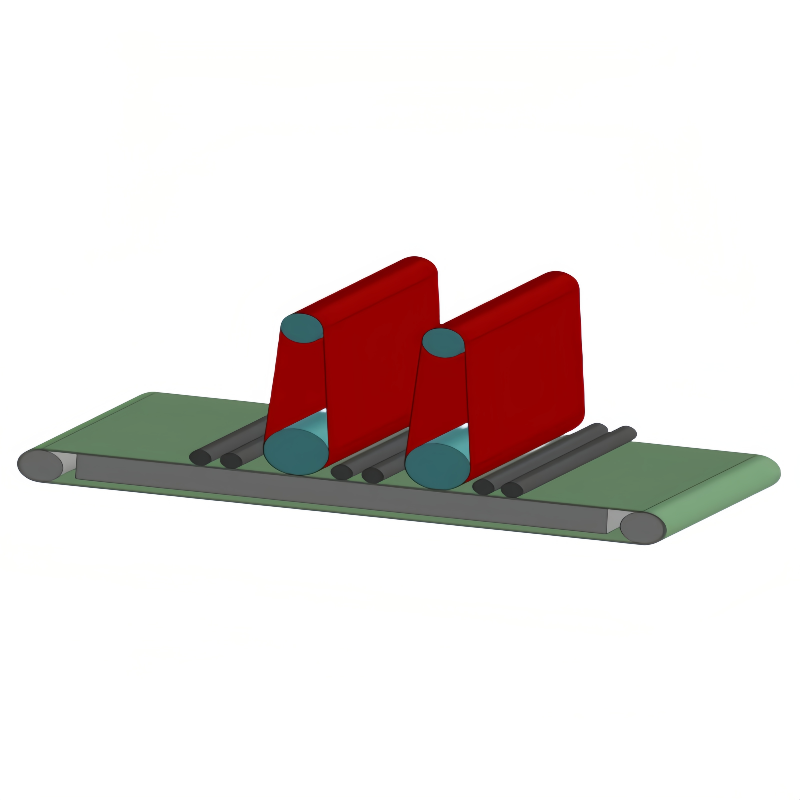

1000mm Wide Belt Sander with Polishing Wheel - Technical Specifications and Features Overview

The RR1000, RRR1000 are industrial-grade wide belt sanders designed for high-efficiency material finishing, calibration, deburring, and polishing. These machines are equipped with multiple sanding belts and, in some models, a polishing wheel, offering a broad range of applications in industries such as metalworking, woodworking, automotive, and aerospace. Below is an in-depth look at the features and specifications of each model:

Technical Specifications

| Parameter | Unit | RR1000 | RRR1000 | RR1300 | RRP1300 |

| Max Working Width | mm | 1000 | 1000 | 1300 | 1300 |

| Max Working Height | mm | 60 | 60 | 60 | 60 |

| Min Workpiece Length | mm | 250 | 250 | 350 | 350 |

| First Sanding Belt Power | kW | 15 | 15 | 30 | 30 |

| Second Sanding Belt Power | kW | 11 | 11 | 22 | 22 |

| Third Sanding Belt Power | kW | / | 11 | / | / |

| Polishing Wheel Power | kW | / | / | / | 15 |

| Rotating Motor Power | kW | / | / | / | / |

| Feeding Motor Power | kW | 3 | 3 | 4 | 4 |

| Vertical Adjustment Power | kW | 0.37 | 0.37 | 0.55 | 0.55 |

| Oscillating Motor Power | kW | / | / | / | 2.2 |

| Vacuum Motor Power | kW | / | / | / | / |

| Machine Dimensions | m | 2.3 x 2.1 x 2 | 2.6 x 2.1 x 2 | 2.8 x 2.4 x 2.1 | 3.1 x 2.4 x 2.1 |

| Machine Weight | kg | 2500 | 2900 | 3500 | 3800 |

| Sanding Belt Size | mm | 2000 x 1050 | 2000 x 1050 | 2200 x 1350 | 2200 x 1350 |

Overview of the Models

These wide belt sanders are highly versatile and designed to cater to different material finishing needs, from heavy-duty sanding to fine polishing. The inclusion of multiple sanding belts and polishing wheels ensures that these machines can handle complex operations such as deburring, edge rounding, thickness calibration, and achieving smooth, glossy finishes.

Key Features and Functions

Wide Belt Sanding: All models are equipped with powerful sanding belts, with the first belt typically providing coarse sanding for material removal, while the second belt focuses on finer sanding or smoothing the surface. Depending on the model, a third belt may be available for an additional layer of sanding, improving finishing precision.

The RR1000 and RRR1000 models feature a combination of a 15 kW first sanding belt and an 11 kW second sanding belt, ideal for standard sanding tasks.

The RR1300 and RRP1300 models use higher-power configurations (30 kW and 22 kW respectively) to handle more demanding tasks such as high material removal rates and processing of larger workpieces.

Polishing Wheel (RRP1300): The RRP1300 model is equipped with a polishing wheel to provide a final smooth finish, especially for applications where a high-gloss surface is required. This feature eliminates the need for a separate polishing step, streamlining the production process.

Powerful Feeding System: The feeding motor, with power ranging from 3 kW to 4 kW, ensures stable and efficient movement of the workpiece through the machine. The feeding mechanism supports high-speed material processing and consistent movement, ensuring even sanding and finishing along the entire length of the workpiece.

Vertical Adjustment and Oscillating Motors: These machines feature vertical adjustment motors for easy height adjustments, allowing for greater flexibility when processing different material thicknesses. The oscillating motor (available in models RR1300 and RRP1300) ensures that the sanding belts distribute pressure evenly across the workpiece, providing uniform results.

Customization for Different Materials: The machines are designed to handle a wide range of materials, including metals (steel, aluminum, copper), plastics, and even some types of wood. The adjustable settings for belt pressure, speed, and oscillation enable the machine to be tailored for specific material types and surface finishing requirements.

User-Friendly Controls: All models come with a user-friendly control panel that allows operators to adjust machine settings quickly and efficiently. With digital controls, it is easier to set the sanding belt speeds, feeding rates, and vertical adjustments for optimal results.

Applications

The 1000mm/1300mm Wide Belt Sanding Machines are widely used in industries that require high-efficiency material finishing. These include:

Metalworking: Ideal for finishing and deburring metal parts, these machines are used in industries such as automotive, aerospace, and machinery production. They handle various metals including ferrous and non-ferrous materials.

Woodworking: These machines are also employed in woodworking, especially in the manufacturing of furniture, cabinetry, and other wooden products that require a smooth, uniform surface finish.

Furniture Production: The sanding capabilities of these machines make them ideal for sanding and finishing components of wooden furniture, ensuring a smooth, polished surface.

Plastic and Composite Materials: Due to their versatility, these machines can also be used in sanding plastics and composite materials, often required for precise edge finishing and smoothing.

Benefits of Using the Wide Belt Sander

Increased Efficiency: The combination of high-powered motors, multiple sanding belts, and polishing wheels allows these machines to finish materials quickly and efficiently, reducing production time.

Superior Finish Quality: With the capability to handle both coarse and fine sanding as well as polishing, these machines deliver superior surface finishes that meet the highest standards in the industry.

Consistency: The automated sanding process ensures consistency from part to part, eliminating variations and errors that are common in manual sanding or polishing operations.

Reduced Labor Costs: With automated sanding and polishing features, operators can achieve high-quality finishes without needing to manually handle each workpiece. This reduces labor costs and the potential for human error.

Versatility: The ability to adjust settings for different materials and thicknesses makes these machines adaptable to a wide variety of applications across industries.

Conclusion

The 1000mm Wide Belt Sanding Machines are robust, high-efficiency machines designed to provide high-quality sanding, deburring, and polishing solutions. With their versatile capabilities, powerful motors, and precision control, these machines are perfect for industries requiring consistent and high-quality surface finishes. Whether you are processing metals, plastics, or wood, these machines deliver exceptional results, contributing to increased productivity and reduced operational costs.