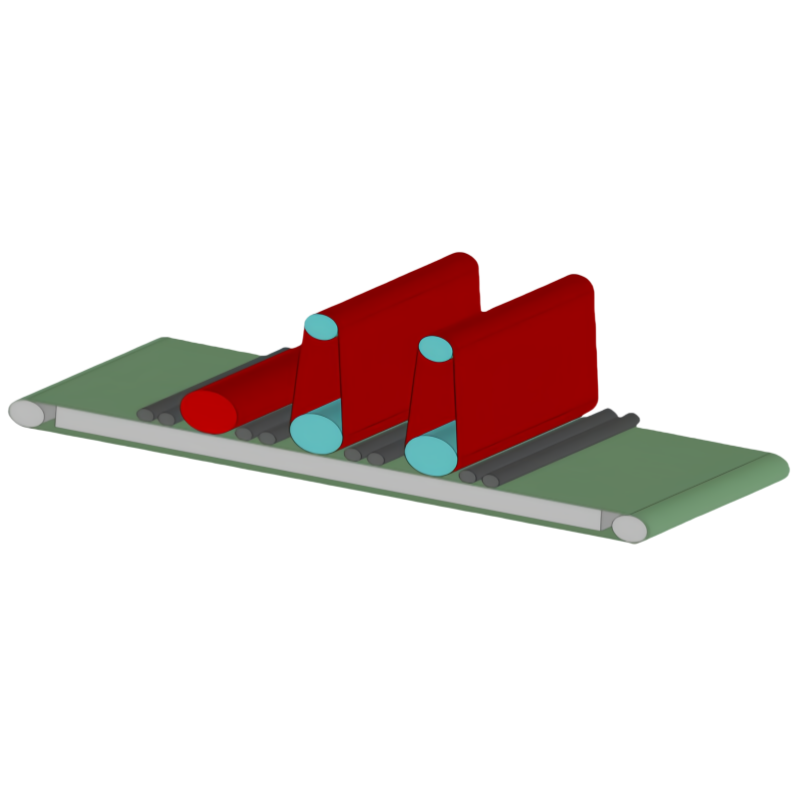

630mm 2-Belt and 1-Polishing Wheel Sanding Machine:

The 630mm 2-Belt and 1-Polishing Wheel Sanding Machine is a high-performance industrial tool designed for advanced metal and material surface finishing, deburring, calibration, and polishing applications. Whether used for fine-tuning the dimensions of a workpiece or for achieving a smooth, refined surface finish, this machine delivers precision and versatility across a range of industries including metalworking, woodworking, automotive, aerospace, and furniture production.

Technical Specifications

| Parameter | Unit | R630 | RR630 | RP630 | RRR630 | RRP630 |

| Maximum Working Width | mm | 630 | 630 | 630 | 630 | 630 |

| Maximum Working Height | mm | 60 | 60 | 60 | 60 | 60 |

| Minimum Working Length | mm | 220 | 220 | 220 | 220 | 220 |

| 1st Sanding Belt Power | kW | 15 | 15 | 15 | 15 | 15 |

| 2nd Sanding Belt Power | kW | - | 11 | - | 11 | 11 |

| 3rd Sanding Belt Power | kW | - | - | - | 11 | - |

| Polishing Wheel Power | kW | - | - | 11 | - | 11 |

| Rotary Motor Power | kW | - | - | - | - | - |

| Feeding Motor Power | kW | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 |

| Lifting Motor Power | kW | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 |

| Oscillation Motor Power | kW | - | - | 1.5 | - | 1.5 |

| Vacuum Motor Power | kW | - | - | - | - | - |

| Machine Dimensions | m | 1.8×1.9×2 | 2.1×1.9×2 | 2.1×1.9×2 | 2.4×1.9×2 | 2.4×1.9×2 |

| Machine Weight | kg | 1400 | 1600 | 1600 | 1800 | 1800 |

| Sanding Belt Size | mm | 1900×630 | 1900×630 | 1900×630 | 1900×630 | 1900×630 |

Machine Model Overview

R630 / RR630 / RP630 / RRR630 / RRP630

R630: Ideal for applications requiring high sanding power and efficiency with basic configurations. This model provides significant sanding capacity and smooth surface finishes for medium-sized workpieces.

RR630 / RP630: These models come with enhanced motor power, including additional power for the second sanding belt. The RR630 and RP630 configurations allow for more specific finishing and deburring capabilities with multiple sanding belts, providing a more polished finish on metal surfaces.

RRR630 / RRP630: These are the top-tier models in the range, designed with high-end features, including multiple sanding belts, polishing wheels, and oscillation motors for additional finishing stages. The RRR630 and RRP630 can handle complex deburring and surface treatment tasks with precision.

Applications

The 24.8-inch (630mm) Wide Belt Sanders are commonly used in a variety of industries for processing different types of metal, including:

Automotive Manufacturing: Surface preparation for parts like body panels, chassis components, and engine parts.

Metal Fabrication: Finishing of cut or welded parts from steel, aluminum, and other metals, ensuring a smooth and consistent surface.

Aerospace: Precision sanding and deburring of metal parts used in aircraft manufacturing.

Heavy Equipment Manufacturing: Calibration, deburring, and surface finishing of large metal components.

Construction: Sanding and finishing of metal profiles, pipes, and steel plates used in building structures.

Key Features & Specifications

Maximum Working Width: 630mm (24.8 inches)

Maximum Working Height: 60mm

Minimum Workpiece Length: 220mm

Belt Configuration: 2 sanding belts, 1 polishing wheel

Sanding Belt Power:

Polishing Wheel Power: 11 kW

Feeding Power: 1.5-2.2 kW

Vertical Adjustment Power: 0.37 kW

Oscillating Motor Power: 1.5 kW

Machine Dimensions: 2.1m x 1.9m x 2m (approximately 6.9’ x 6.2’ x 6.6’)

Machine Weight: 1600 kg (approx. 3527 lbs)

Sanding Belt Size: 1900mm x 630mm

Machine Overview

The 630mm 2-Belt and 1-Polishing Wheel Sanding Machine is engineered to handle a variety of surface treatment tasks with high accuracy and efficiency. It is primarily used in industries that require high-quality metal and wood finishing, such as automotive, aerospace, metalworking, and woodworking.

Sanding Belts: The machine utilizes two powerful sanding belts for efficient material removal. The first sanding belt, equipped with 15 kW of power, is typically used for coarse sanding and material removal, while the second belt, powered by 11 kW, provides a finer finish. With the ability to adjust the sanding pressure and speed, the machine can handle a wide range of materials, including steel, aluminum, and wood.

Polishing Wheel: The polishing wheel is designed to provide a smooth and glossy finish after the sanding process. Operating at 11 kW, it delivers fine polishing and deburring, ensuring that the workpieces meet high-quality standards. The integration of the polishing wheel also reduces the need for manual finishing, improving production efficiency.

Precision and Accuracy: With a feed power of up to 2.2 kW, the machine can handle a variety of materials and thicknesses with exceptional precision. The system ensures smooth and consistent processing of the material, reducing defects and enhancing the overall surface quality.

Variable Speed Control: The machine features adjustable settings for both sanding and polishing wheels. This gives the operator full control over the speed, pressure, and other parameters to tailor the process to specific requirements. The oscillating motor also contributes to the even distribution of sanding and polishing action across the material.

Ergonomically Designed Worktable: The sanding machine features a robust worktable that ensures a stable platform for the workpiece. The height and angle of the worktable can be adjusted to optimize the sanding process, ensuring that workpieces are held in the correct position for efficient treatment.

Applications

Metal Finishing: This machine is ideal for applications in metalworking, including deburring, polishing, and fine sanding of metal surfaces. It is particularly suitable for automotive parts, aerospace components, and machinery parts where precision and surface finish are critical.

Calibration: The 2-belt configuration ensures consistent thickness reduction and surface flattening, making it suitable for calibration tasks in both metalworking and woodworking industries.

Woodworking: Though it is optimized for metal, the machine can also be used for sanding wood and other materials, particularly for finishing furniture or cabinet components. The polishing wheel provides an ideal solution for smoothing and enhancing the finish of wood pieces.

Aerospace and Automotive Applications: Given the high precision required in these industries, this machine is invaluable for the polishing and deburring of small and large components used in cars, airplanes, and other high-precision machinery.

Benefits

Enhanced Efficiency: The combination of two sanding belts and a polishing wheel ensures that the machine can process materials in a more efficient and less time-consuming manner. This significantly reduces production costs and increases throughput.

Superior Surface Finish: The fine polishing capabilities of the machine ensure that workpieces not only achieve the desired dimensions but also possess a smooth, high-quality finish. The result is a product that meets both aesthetic and functional requirements.

Versatility: This machine is highly versatile, capable of working with a variety of materials including ferrous and non-ferrous metals, wood, plastics, and composites. Whether for rough sanding or fine polishing, it adapts to meet specific finishing needs.

Customizable Settings: The adjustable speed, pressure, and oscillation settings enable the machine to be customized for specific tasks, allowing operators to fine-tune the machine to suit their unique production requirements.

Reduced Labor Costs: By automating key sanding and polishing tasks, the machine reduces the need for manual labor, allowing businesses to streamline production processes and reduce labor costs.

Precision and Reliability: The powerful motors and advanced design ensure that the machine operates reliably with minimal maintenance. The precision of the machine allows for consistent, high-quality results, ensuring that every workpiece meets stringent requirements.