Industrial Nitrogen Generators for Laser Welding

ZHN-L Series Laser Welding Nitrogen Generators

ZHN-03L 60NL/min High Purity Nitrogen Making Machine for Laser Welding Machines

Overview

The ZHN-03L Nitrogen Making Machine is a high-capacity, high-purity nitrogen generator engineered for modern laser welding applications. Delivering 60 NL/min of nitrogen gas with a purity adjustable between 95% and 99.999%, it ensures a continuous, on-demand, and cost-effective supply of nitrogen directly at your facility.

This industrial-grade nitrogen generator eliminates the need for costly bottled nitrogen deliveries, reduces downtime, and provides a stable gas supply for optimal welding quality. With intelligent PLC control, integrated air drying and filtration systems, and a user-friendly interface, the ZHN-03L is designed to meet the rigorous demands of manufacturing workshops, metal fabrication plants, and large-scale production lines.

Key Features & Advantages

1. High Capacity for Industrial Production

With an output of 60NL/min, the ZHN-03L is ideal for high-volume welding operations, including robotic welding cells and multi-machine setups.

Supports multiple welding stations simultaneously

Maintains stable nitrogen flow under heavy-duty usage

Reduces operational interruptions caused by gas shortages

2. Adjustable High Purity (95% – 99.999%)

Different welding materials and applications require different nitrogen purity levels. The ZHN-03L offers flexible purity settings to match your needs:

3. PLC Intelligent Control System

An advanced Programmable Logic Controller (PLC) ensures fully automated, stable, and energy-efficient operation:

Monitors flow rate, purity, and pressure in real-time

Automatically adjusts system performance to match demand

Provides alarm notifications for maintenance and fault conditions

Saves energy by optimizing compressor and filtration cycles

4. Integrated Refrigerated Air Dryer

Moisture in compressed air can degrade nitrogen purity and damage welding quality. The ZHN-03L integrates a high-performance refrigerated air dryer to:

Remove moisture before gas separation

Prevent oxidation and contamination during welding

Prolong the life of filters and separation modules

5. Triple Filtration System for Ultra-Clean Gas

The ZHN-03L uses a three-stage filtration process to guarantee ultra-pure nitrogen:

Primary Filter: Removes large particles, dust, and water droplets

Fine Filter: Captures micro-particles and oil aerosols

High-Efficiency Filter: Ensures the nitrogen meets high-purity standards for sensitive welding applications

6. Automatic Condensate Drainage

An automatic drainage system discharges accumulated moisture without manual intervention, reducing maintenance time and keeping the system in optimal condition.

7. Direct Air Compressor Integration

Designed for easy installation, the ZHN-03L connects directly to your existing air compressor for immediate nitrogen production—no external storage tanks required.

8. 7-Inch Multilingual Touchscreen

The user-friendly touchscreen provides:

Real-time operational data

Easy access to system settings

Multi-language interface for global use

Step-by-step troubleshooting guidance

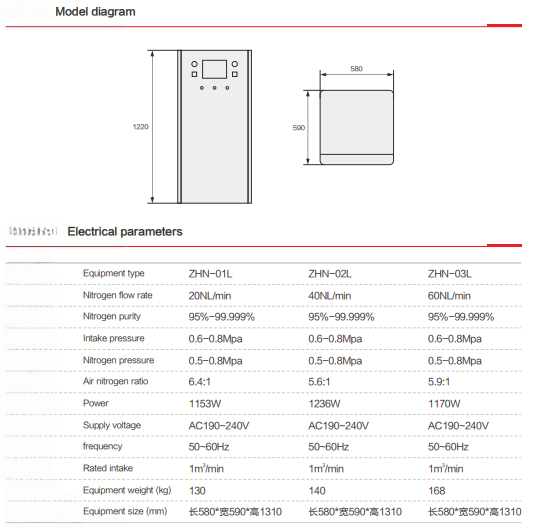

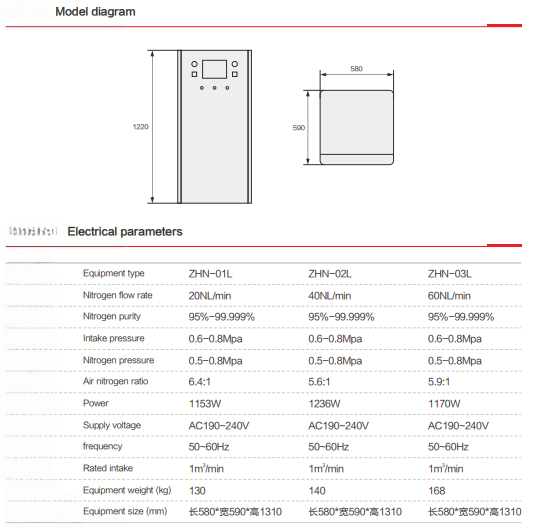

Technical Specifications

| Model | Nitrogen Flow Rate | Nitrogen Purity | Intake Pressure | Nitrogen Pressure | Air:Nitrogen Ratio | Power | Supply Voltage | Frequency | Rated Intake | Weight (kg) | Dimensions (mm) |

| ZHN-03L | 60 NL/min | 95% – 99.999% | 0.6 – 0.8 MPa | 0.5 – 0.8 MPa | 5.9 : 1 | 170 W | AC 190–240 V | 50–60 Hz | 3.1 m³/min | 168 | 580×590×1310 |

Applications in Laser Welding

The ZHN-03L is widely used in:

Fiber Laser Welding Machines – For high-precision welding with clean and strong joints

Handheld Laser Welders – Stable nitrogen supply for mobile welding jobs

Robotic Welding Lines – Continuous, high-purity nitrogen for automated production

Specialty Welding – Ideal for stainless steel, aluminum, titanium, and other reactive metals

Performance Benefits in Welding:

Oxidation Prevention: Protects molten welds from oxygen exposure

Improved Appearance: Produces bright, smooth, and consistent weld seams

Reduced Porosity: Minimizes trapped gases for stronger welds

Repeatable Quality: Stable purity and pressure ensure identical results across batches

Comparison with Cylinder Nitrogen Supply

| ZHN-03L Nitrogen Generator | Bottled Nitrogen Supply |

| On-site production, never runs out | Limited by delivery schedule |

| Adjustable purity (95%–99.999%) | Fixed purity only |

| No transport or rental costs | High recurring expenses |

| Minimal storage space required | Large storage area for cylinders |

| Continuous supply for 24/7 operation | Frequent changeovers interrupt work |

Installation & Operation

The ZHN-03L is plug-and-play:

Connect to your compressed air source

Attach nitrogen outlet to your welding machine

Select desired purity and flow rate on the touchscreen

Start the system and let the PLC handle the rest

The system runs automatically, maintaining the required purity and flow without manual adjustments.

Maintenance & Service

Quick Filter Replacement: Tool-free, easy-to-access design

Automatic Drainage: Reduces manual intervention

Durable Components: Long service life with minimal wear

Remote & Local Support: Global technical assistance and spare parts supply

Environmental & Cost Benefits

Up to 80% Cost Savings over bottled nitrogen

Reduced CO₂ Emissions by eliminating transport trucks

No Gas Waste – Produce only what you need, when you need it

Conclusion

The ZHN-03L 60NL/min High Purity Nitrogen Making Machine is the ultimate nitrogen supply solution for medium to large-scale laser welding operations. With adjustable purity, high flow capacity, integrated air treatment, and intelligent control, it delivers consistent welding gas quality while significantly cutting costs and environmental impact.

Whether for a single high-capacity welding line or multiple machines in parallel, the ZHN-03L provides the reliability, performance, and efficiency your production demands.