2000mm Sheet Metal Deburring Machine - High-Efficiency Metal Processing Solution

The 2000mm Sheet Metal Deburring Machine is an advanced industrial equipment designed for heavy-duty deburring, edge rounding, oxide removal, and surface finishing of large sheet metal workpieces. This versatile machine is specifically engineered to handle metal sheets up to 2000mm in width and can process a wide range of metals, including stainless steel, aluminum, carbon steel, copper, and various non-ferrous alloys. It is ideal for industries that require high-volume metal processing with consistent, high-quality results, such as automotive, aerospace, construction, and manufacturing.

Key Features and Benefits

1. Large Processing CapacityThe 2000mm sheet metal deburring machine accommodates large sheets and heavy workpieces with ease. Its robust design allows for seamless processing of sheet metal widths up to 2000mm and thicknesses ranging from 0.5mm to 80mm. The machine’s wide processing range makes it suitable for a variety of applications, from delicate, thin sheets to thicker, more substantial materials.

2. Precision Deburring and Edge RoundingThe machine features advanced deburring tools, including powerful sanding belts and rotary brush heads, to provide precise burr removal and uniform edge rounding. The sanding belts remove coarse burrs and slag particles, while the rotary brush heads ensure smooth, rounded edges and corners with a consistent small-radius finish. This process, often referred to as achieving an R-arc effect, is essential for creating parts with smooth, polished edges, reducing the risk of metal fatigue, and improving both safety and functionality.

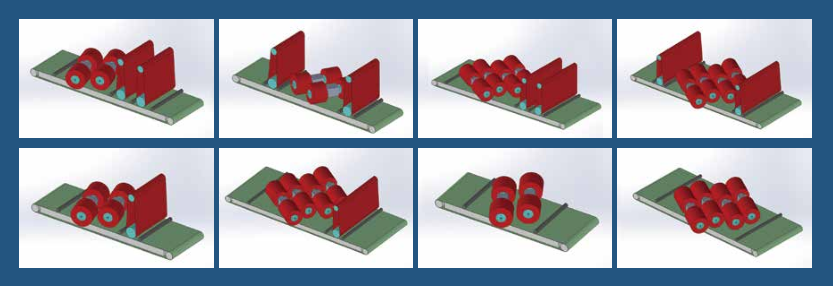

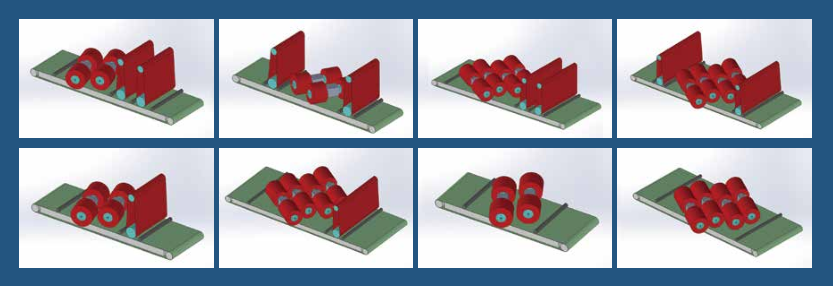

3. Versatility in OperationThe 2000mm deburring machine offers versatile functionality, allowing the sanding belt station and rotary brush head stations to operate independently. The sanding belt system is ideal for surface brushing, oxide removal, and slag elimination. The rotary brush heads, on the other hand, provide 360° deburring for intricate components, including laser-cut and CNC-punched parts. This independence in operation allows users to tailor the machine's settings for different processing requirements, enhancing flexibility and efficiency.

4. Efficient Conveyor SystemThe machine is equipped with an advanced conveyor system that uses a magnetic and vacuum feed mechanism to securely hold workpieces during processing. The conveyor speed is adjustable via frequency control, allowing for customization based on the material and desired processing speed. This high-tech conveyor system guarantees precise part positioning and smooth, continuous processing, even for larger, heavier workpieces.

5. Dust Collection and Environmental SafetyEquipped with an integrated dust extraction system, the machine ensures a clean and safe working environment. The wet-type dust collector traps grinding dust using water spray, effectively filtering out metal particles and preventing hazardous emissions. The high-efficiency filtration system also recycles metal powder, reducing waste and making the process environmentally friendly. This dust control system is a critical feature for complying with safety standards and maintaining workplace health.

6. Easy Operation and ControlThe 2000mm deburring machine is designed with user-friendly controls, featuring a touchscreen interface that allows operators to easily set parameters and monitor the machine's performance. This intuitive interface simplifies the operation process, reducing the likelihood of operator error and minimizing downtime. The machine also includes an advanced PLC control system that enables precise adjustments for all key settings, ensuring high-quality results with minimal manual intervention.

7. High-Quality FinishesOne of the standout features of the 2000mm deburring machine is its ability to produce high-quality finishes consistently across large volumes of workpieces. The combination of sanding belts and rotary brushes creates a smooth, uniform surface on metal parts, which is crucial for industries where aesthetics and functionality are paramount. The machine also ensures that all parts undergo consistent treatment, eliminating imperfections, rough edges, and burrs.

Technical Specifications

Processing Width: ≤2000mm

Processing Thickness: 0.5mm ~ 80mm

Minimum Part Size: 50mm x 50mm (for solid workpieces)

Total Machine Power: 100kW

Sand Belt Size: Φ3000mm × 2000mm

Disc Brush Size: Φ500mm × 800mm

Conveyor Speed: 0.5 ~ 6 m/min, adjustable via frequency control

Sand Belt Linear Speed: 20 m/s

Disc Brush Rotation Speed: 10 ~ 30 m/s, adjustable via frequency control

Disc Brush Revolution Speed: 2 ~ 20 r/min, adjustable via frequency control

Number of Planetary Revolution Brush Heads: 1 unit

Number of Planetary Rotation Brush Heads: 10 units

Processing Thickness Servo Adjustment Precision: 0.01mm

Brush Compensation Servo Adjustment Precision: 0.01mm

Grinding Consumables: Sand belt + disc brush

Dust Extraction Volume: 8000 m³/h

Dimensions: Length 5500mm × Width 3200mm × Height 2500mm

Machine Weight: Approximately 8T

Applications

The 2000mm sheet metal deburring machine is particularly effective in industries where large volumes of sheet metal parts need precise finishing. Some of the primary applications include:

Automotive Manufacturing: Removing burrs and providing smooth edges on car body parts, frames, and other components.

Aerospace: Deburring and finishing metal parts used in aircraft assembly, ensuring compliance with stringent industry standards.

Metal Fabrication: Suitable for processing large quantities of metal sheets, including parts for machinery, appliances, and structural elements.

Construction: For deburring and finishing metal sheets used in construction materials, providing uniform edge rounding and a clean surface.

Electronics: Ensuring precise, burr-free edges for components used in electronic devices, where performance and aesthetics are critical.

Conclusion

The 2000mm Sheet Metal Deburring Machine is a high-capacity, precision-engineered solution for the heavy-duty deburring and finishing of large sheet metal parts. With its robust construction, advanced functionality, and environmentally-friendly features, this machine provides manufacturers with an efficient, reliable, and cost-effective way to process metal sheets for various industries. Whether for high-volume production or complex part designs, this machine guarantees high-quality, consistent results every time.