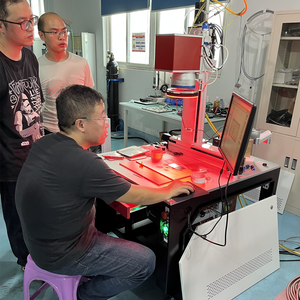

ZS100 Fiber Laser Jewelry Spot Welding Machine

High-Power Desktop Laser Welder for Professional Jewelry Manufacturing & Repair

The ZS100 Fiber Laser Jewelry Spot Welding Machine is a high-performance desktop laser welder designed for professional jewelry production and precision repair.

Equipped with a 100W fiber laser source, the ZS100 delivers higher pulse energy, deeper penetration, and superior welding stability compared with lower-power models, making it ideal for both fine and demanding jewelry welding tasks.

High-Efficiency Fiber Laser Technology

The ZS100 uses an advanced fiber laser generator with excellent beam quality and outstanding energy efficiency.

Laser output power: ≥100W

Maximum pulse energy: 10J

Electro-optical conversion efficiency up to 30%

Power stability ≤ 1.5%, ensuring consistent welding results

No noticeable power attenuation for 3–5 years of continuous use

This technology provides a major advantage over traditional YAG laser welding machines, especially in long-term reliability and operating cost.

Precision Spot Welding Performance

The ZS100 is engineered for high-precision jewelry welding, even on delicate or intricate designs.

Adjustable spot size: 0.3 – 1.5 mm

3× electric beam expander for accurate and repeatable spot control

Pulse width adjustable from 0.5 to 50 ms

Maximum frequency: 50 Hz

Minimal heat-affected zone, preventing deformation, cracks, or discoloration

The result is clean, strong, and visually flawless welds, even on thin chains and fine prongs.

Maintenance-Free Air Cooling System

Unlike traditional YAG jewelry welders, the ZS100 adopts a forced air-cooling design.

No water chiller required

No risk of water leakage

Lower maintenance and operating costs

Compact structure ideal for desktop use

This makes the ZS100 especially suitable for jewelry workshops, retail repair counters, and small factories.

Energy-Saving & Environmentally Friendly Design

Total machine power consumption: 500W

No consumables such as xenon lamps or crystal rods

No chemicals, fumes, or wastewater

Quiet and clean operation

The ZS100 significantly reduces long-term operating costs while meeting modern environmental requirements.

Wide Range of Jewelry Applications

The ZS100 is widely used for:

Gold, silver, and platinum jewelry welding

Ring resizing and reinforcement

Necklace, chain, pendant, and bracelet welding

Claw and prong repair

Micro-welding of fine jewelry components

Custom jewelry making and professional repair

Compatible materials:

Technical Specifications (ZS100)

Laser type: Fiber laser generator

Laser power: ≥100W

Max pulse energy: 10J

Pulse width: 0.5–50 ms

Frequency: Up to 50 Hz

Energy stability: ≤1.5%

Spot size: 0.3–1.5 mm

Cooling method: Forced air cooling

Power supply: 110V–240V, 50/60Hz

Machine size (L×W×H): 550 × 300 × 430 mm

Net weight: 25 kg

Working temperature: 10–45°C

Relative humidity: 20%–85%

ZS100 vs Traditional YAG Jewelry Laser Welder

| Item | ZS100 Fiber Laser | YAG Laser |

|---|

| Cooling | Air-cooled | Water-cooled |

| Maintenance | Maintenance-free | Regular maintenance |

| Energy efficiency | ~30% | ~3% |

| Consumables | None | Xenon lamp, crystal rod |

| Service life | Up to 100,000 hours | Shorter, frequent replacements |

| Operating cost | Low | High |