60W Jewelry Laser Spot Welding Machine with CCD Touch Screen Mini Portable Welder for Gold Silver Chain Ring Repair

Product Overview

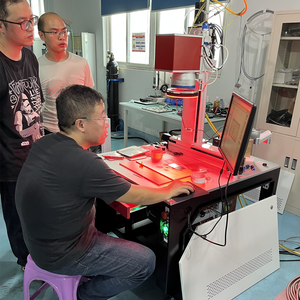

The 60W Jewelry Laser Spot Welding Machine is a high-precision, mini portable laser welding system specially designed for jewelry manufacturing, repair, and micro metal processing. Equipped with an integrated CCD camera and touch screen control panel, this machine allows operators to accurately observe, position, and weld even the smallest jewelry components with excellent consistency and reliability.

It is widely used for gold, silver, stainless steel, titanium, and other precision metals, making it an ideal solution for jewelry workshops, retail repair shops, factories, and DIY jewelry studios.

Advanced CCD Visual Positioning System

The built-in CCD camera combined with a microscope system provides clear, real-time magnification of the welding area. This visual positioning system ensures:

Accurate alignment of the laser spot

Precise control on micro and thin jewelry parts

Reduced operation errors

Higher welding success rate on complex shapes

Operators can easily perform fine welding tasks such as chain repair, ring resizing, prong welding, crack filling, and micro hole welding.

Touch Screen Control & Easy Operation

The touch screen interface enables intuitive and precise control of welding parameters, including:

Laser pulse frequency

Pulse width

Laser energy output

With simple parameter adjustments, the machine can adapt to different materials, thicknesses, and welding requirements. This user-friendly design reduces training time and allows both experienced professionals and beginners to operate the machine efficiently.

High-Efficiency 60W Laser Welding Performance

Powered by a 60W laser source, this welder delivers:

The adjustable pulse welding mode produces a small heat-affected zone, preventing deformation, discoloration, or damage to surrounding areas. This is especially important for delicate jewelry made of precious metals.

The machine ensures:

Deep and strong weld penetration

Smooth and seamless weld appearance

No porosity or visible welding marks

Mini Portable Design for Jewelry Workshops

The compact desktop structure makes this machine space-saving and easy to install. Its mini portable design is ideal for:

Jewelry retail stores

Small workshops

Mobile repair services

Despite its small size, the machine supports long-term and continuous operation, maintaining stable performance during extended working hours.

Reliable Cooling & Continuous Operation

The efficient cooling system ensures stable temperature control, allowing the welder to:

This reliability makes it suitable for daily production and high-frequency repair tasks.

Key Advantages

High-precision laser spot welding

Integrated CCD camera & microscope

Touch screen control for easy operation

Small heat-affected zone, no deformation

Clean, strong welds with excellent appearance

Compact, portable, and space-saving design

Suitable for professional and DIY jewelry repair

Typical Applications

Gold and silver jewelry welding

Chain and ring repair

Prong welding and stone setting repair

Jewelry resizing and crack repair

Stainless steel and titanium micro-welding

DIY jewelry making and customization

Technical Parameters

Laser Output Power: 60 W

Laser Type: YAG Laser

Laser Frequency: 1.0 – 15.0 Hz (Adjustable)

Pulse Width: 0.1 – 15 ms (Step Adjustable)

Spot Adjustment Range: ±3 mm

Single Pulse Energy: 50 J

Aiming & Positioning: Integrated CCD Camera & Microscope

Cooling System: Built-in Water Chiller

Operation Method: Touch Screen Control

Operating Temperature: ≤45°C

Input Voltage: AC 220V ±10%, 50Hz

Power Consumption: 2.5 kW

Machine Dimensions & Weight

Display Touch Screen Installation Size: 137 × 190 mm

Machine Dimensions (L × W × H): 510 × 295 × 395 mm

Net Weight: Approx. 30 kg