Fiber Laser Jewelry Spot Welding Machine (ZS60 / ZS100)

High-Precision, Maintenance-Free Jewelry Welding Solution

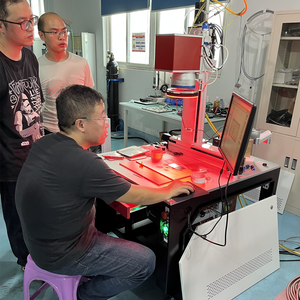

The ZS60 / ZS100 Fiber Laser Jewelry Spot Welding Machine is a next-generation desktop fiber laser welder designed specifically for high-precision jewelry manufacturing and repair.

Using advanced fiber laser technology, this machine delivers stable output power, high energy efficiency, and extremely fine welding spots, making it an ideal replacement for traditional YAG jewelry welding machines.

Key Features & Advantages

Advanced Fiber Laser Technology

Equipped with a high-efficiency fiber laser generator with excellent beam quality

Electro-optical conversion efficiency up to 30%, approximately 10 times higher than YAG lasers

Stable laser output with no power attenuation for 3–5 years

High Precision Spot Welding

Adjustable laser spot size from 0.3 to 1.5 mm

3× electric beam expander for precise control of weld spot size

Pulse energy up to 6J (ZS60) and 10J (ZS100) ensures strong, clean welds

Minimal heat-affected zone, preventing deformation or discoloration

Maintenance-Free Air Cooling System

Forced air-cooled design, no water chiller required

Eliminates risks of water leakage and reduces maintenance costs

Compact structure suitable for workshops, retail stores, and repair studios

Energy Efficient & Environmentally Friendly

Low power consumption: 300W (ZS60) / 500W (ZS100)

No consumables such as xenon lamps or crystal rods

No chemicals, fumes, or pollution during operation

Applications

The ZS60 / ZS100 laser welding machine is widely used for:

Gold, silver, and platinum jewelry welding

Ring resizing and repair

Chain, necklace, pendant, and bracelet welding

Jewelry claw setting reinforcement

Fine and micro-part welding

DIY jewelry customization and professional jewelry repair

Compatible materials:

Technical Specifications (Summary)

Laser type: Fiber laser generator

Laser power: ≥60W / ≥100W

Max pulse energy: 6J / 10J

Pulse width: 0.5–50 ms

Frequency: Up to 50 Hz

Energy stability: ≤1.5%

Cooling system: Forced air cooling

Power supply: 110V–240V, 50/60Hz

Net weight: 20 kg / 25 kg

Fiber Laser vs YAG Jewelry Welding Machine

Fiber Laser Jewelry Welder

Air-cooled, maintenance-free

No consumable parts

High energy efficiency (30%)

Long service life up to 100,000 hours

Stable power output for long-term operation

Traditional YAG Jewelry Welder

Water-cooled, requires regular maintenance

Requires replacement of xenon lamps and crystal rods

Low energy efficiency (around 3%)

Higher operating and maintenance costs