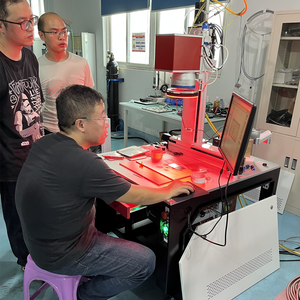

60W Jewelry Laser Spot Welding Machine with CCD Touch Screen Mini Portable Welder for Gold Silver Chain Ring Repair

Product Overview

The 60W Jewelry Laser Spot Welding Machine is a high-precision, compact, and portable laser welding system designed for jewelry manufacturing, repair, and micro metal processing. With its built-in CCD camera and touch screen control, this mini portable welder allows precise positioning and accurate spot welding even on delicate jewelry components.

It is ideal for gold, silver, stainless steel, titanium, and other precious metals, making it perfect for jewelry workshops, retail repair shops, and DIY jewelry creators.

Key Features

CCD Camera & Microscope: Provides real-time magnification for precise weld alignment.

Touch Screen Control: Intuitive interface for adjusting laser power, pulse width, and frequency.

Adjustable Pulse Frequency: Ensures fast, stable, and precise welding on different materials.

Minimal Heat-Affected Zone: Prevents deformation, discoloration, or damage to surrounding areas.

Compact & Portable: Desktop-friendly, saves workspace and is easy to move.

Continuous Operation: Efficient cooling system allows extended 24-hour use.

Versatile Applications: Ideal for chains, rings, pendants, earrings, and other fine jewelry components.

Technical Specifications

Laser Power: 60 W

Pulse Energy: 50 J

Pulse Frequency: 1–15 Hz (adjustable)

Pulse Width: 0.1–15 ms (adjustable)

Spot Size: 0.3–1.5 mm (adjustable)

Positioning: CCD camera with integrated microscope

Cooling System: Air-cooled

Operation Method: Touch screen control

Input Voltage: AC 220V ±10%, 50Hz

Machine Dimensions: 510 × 295 × 395 mm

Weight: Approx. 30 kg

Advantages

High-speed, high-efficiency spot welding

Precise and clean welds with strong joint strength

Small heat-affected zone, no visible deformation

Suitable for both professional and DIY users

Portable and compact design for small workshops or mobile repair services

Stable performance for continuous operation

Applications

Gold and silver jewelry welding and repair

Chain, ring, pendant, and earring repair

Jewelry resizing and crack repair

Stainless steel and titanium micro-welding

DIY jewelry making and customization

Machine Dimensions & Weight

Display Touch Screen Installation Size: 137 × 190 mm

Machine Dimensions (L × W × H): 510 × 295 × 395 mm

Net Weight: Approx. 30 kg