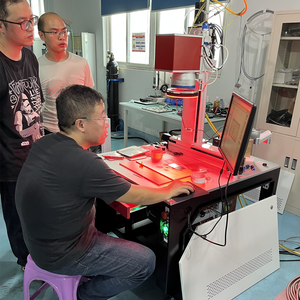

60W Fiber Laser Jewelry Welding Machine for Gold Silver Precision Spot Welding in Jewelry Repair and Manufacturing

✅ Detailed Product Description

The ZS60 Fiber Laser Jewelry Welding Machine is a compact, high-precision laser spot welding system specially designed for jewelry manufacturing, repair, and fine metal processing. It adopts an advanced fiber laser generator, delivering stable output power, high electro-optical efficiency, and long service life, making it a superior alternative to traditional YAG jewelry welding machines.

This machine is widely used for gold, silver, platinum, stainless steel, and other precious or precision metals, providing clean, strong, and visually perfect weld seams with minimal heat impact.

Advanced Fiber Laser Technology

The ZS60 uses a fiber laser source with a rated power of ≥60W, offering:

High beam quality and excellent energy concentration

Stable laser output with energy fluctuation ≤1.5%

No consumables such as xenon lamps or crystal rods

Long lifespan up to 100,000 working hours

Compared with YAG laser welders, fiber laser technology provides 10× higher electro-optical efficiency (up to 30%), ensuring lower energy consumption and reduced operating costs.

Precision Spot Welding Performance

Maximum pulse energy: 6J

Pulse frequency: up to 50Hz

Pulse width: 0.5–50 ms adjustable

Spot size range: 0.3–1.5 mm

Spot adjustment via 3× electric beam expander

These parameters allow the operator to perform ultra-fine welding on delicate jewelry components such as rings, chains, pendants, earrings, clasps, and micro metal parts without deformation or discoloration.

Air-Cooled, Maintenance-Free Design

The ZS60 features a forced air-cooling system, eliminating the need for external water chillers:

This makes the machine ideal for jewelry workshops, retail repair shops, and small production lines.

Energy-Saving & Stable Operation

Total power consumption: ≈300W

Power supply: 110V–240V / 50–60Hz

Working temperature: 10–45°C

Relative humidity: 20%–85%

The machine ensures stable performance even during long working hours, supporting high productivity and consistent welding quality.

Solid Structure & Compact Size

Its desktop design saves space while maintaining excellent rigidity and durability.

Typical Applications

Jewelry manufacturing and repair (gold, silver, platinum)

Chain and ring spot welding

Precision metal component welding

Electronics micro-welding

Dental and laboratory equipment welding

Small automotive precision parts

Fiber Laser vs YAG Laser (Advantages)

Air-cooled system, no chiller required

Much lower energy consumption

No consumable replacement

Stable power output with no yearly attenuation

Longer service life and lower maintenance cost