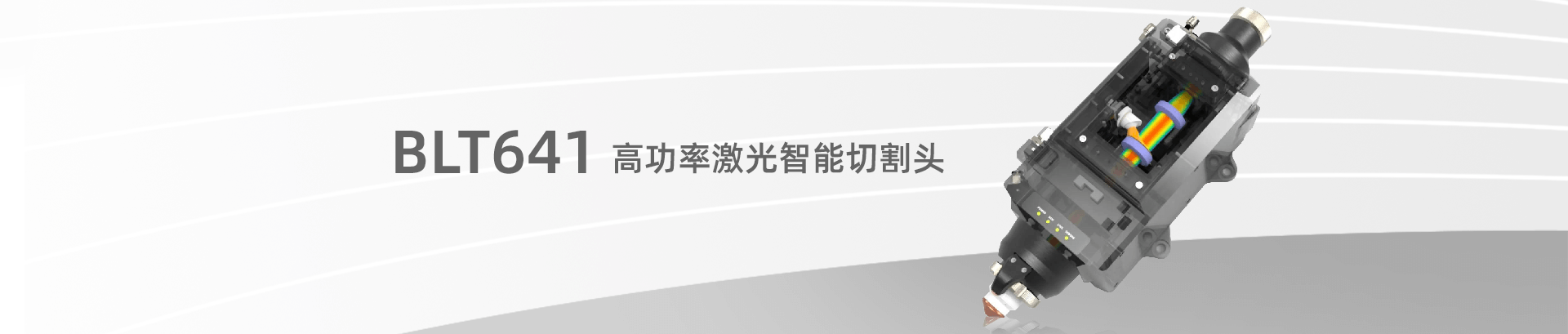

BLT641 series high-power intelligent laser cutting head

The BLT series high-power intelligent laser cutting head is a full-function bus-controlled cutting head specially launched for the sheet metal processing industry. Convenient installation, simple debugging, excellent performance, complete sensors are one of the few intelligent cutting heads on the market.

Specification

Adaptation software

HYPCUT8000 system

Control assembly

BCS200E

Interface Type

POE network cable

Optical solution

focus

Spot magnification factor

2.1 times

Highest power

15KW

total measurement

427*152*137.6

Focus range

+50~-50

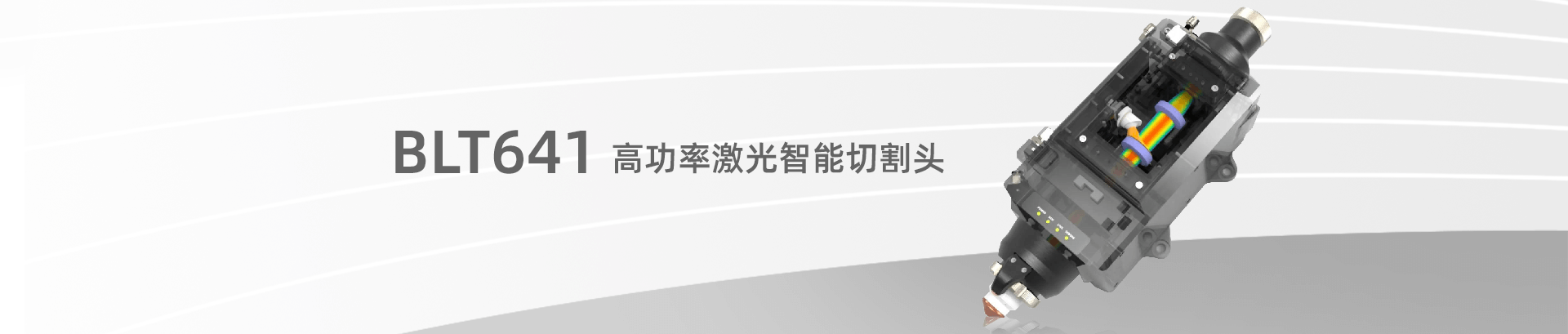

Performance characteristics

Focusing lens temperature

Monitor the state of the focusing lens, and provide quick feedback when the lens is contaminated

Ambient temperature of focusing lens

Monitoring the ambient temperature of the focusing lens, effectively preventing the focusing lens from working at high temperatures

Chamber temperature

Monitor the temperature of the cutting head cavity to prevent high temperature from affecting the optics and affecting the cutting effect

Chamber humidity

Monitor the humidity in the cavity to avoid condensation on the cutting head caused by high humidity

Chamber air pressure

Monitoring chamber air pressure and reliability of chamber sealing

Protective lens temperature

Monitor the status of the protective lens, and provide quick feedback when the lens is contaminated

Cutting air pressure

Monitor the size of the gas flow output during the cutting process, effectively preventing insufficient/excessive air pressure, which affects the quality of the cutting section

capacitance

Monitor the distance between the workpiece and the nozzle

Ambient temperature of sensor head

Monitor the ambient temperature around the sensor head

Cutting gas temperature

Monitor the cutting gas temperature to avoid high temperature gas from affecting the quality of the cutting section

Application industry

Suitable for 6000W-15000W high power fiber laser cutting. Special optimization and upgrades are carried out for specific use environments to achieve long-term reliable and stable operation in daily industrial environments. The use of ultra-precision and ultra-smooth lens processing technology enables the BLT640 cutting head to have excellent cutting quality and speed; achieve seamless docking and deep integration with the system, further improving production and processing efficiency; modular component design, equipment on-site rapid maintenance, customers can quickly Restore production capacity and realize 24-hour uninterrupted production. The localization of service and maintenance further reduces user costs; additional sensors of the same type as BLT831 can dynamically monitor the entire cutting process, directly evaluate and analyze the reasons for changes in cutting ability, collect corresponding key process parameters, and use related algorithms to drive process improvement And optimization, through seamless docking and integration with the cutting system, the intelligent control of laser cutting is finally realized.