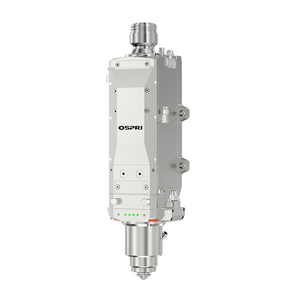

BLT831 series high-power intelligent sheet metal laser cutting head

The BLT series high-power intelligent laser cutting head is a full-function bus-controlled cutting head specially launched for the sheet metal processing industry. Convenient installation, simple debugging, excellent performance, complete sensors are one of the few intelligent cutting heads on the market.

Specification

Adaptation software

HYPCUT8000 system

Control assembly

BCS200E

Interface Type

POE network cable

Optical solution

Variable spot

Spot magnification factor

1.5-4.1 times

Highest power

15KW

total measurement

630*200*160

Focus range

+50~-50

Performance characteristics

Upper (lower) cavity temperature

Monitor the temperature of the cutting head cavity to prevent high temperature from affecting the optics and affecting the cutting effect

Upper (lower) cavity humidity

Monitor the humidity in the cavity to avoid condensation on the cutting head caused by high humidity

Upper (lower) chamber air pressure

Monitoring chamber air pressure and reliability of chamber sealing

Protective lens temperature

Monitor the status of the protective lens and confirm that the condition of the protective lens is always understood to ensure stable and reliable cutting quality

Cutting air pressure

Monitor the size of the gas flow output during the cutting process, effectively preventing insufficient/excessive air pressure, which affects the quality of the cutting section

Capacitive sensor

Monitor the distance between the workpiece and the nozzle

Ambient temperature

Monitor the ambient temperature around the cutting head

Cutting gas temperature

Monitor the cutting gas temperature to avoid high temperature gas from affecting the quality of the cutting section

Application industry

Suitable for 6000W-15000W high power fiber laser cutting. The BLT831 intelligent cutting head adopts ultra-precision opto-mechanical and electrical integration design and development to realize fast and high-precision adjustment of related parameters of the cutting head. Comprehensively integrate various new technologies such as optics, precision machining, electronics, information processing and control, and special software to form a comprehensive advantage. Compared with the current market products, it has simple structure, multiple functions, high efficiency, high precision, etc. Advantages; bus communication, modular design, improve the reliability of the system, and provide users with more flexible system integration; the focus position and focus beam diameter of the cutting head can be adjusted independently of each other, with 1.5x to 4.1x The magnification factor can achieve excellent cutting performance in a variety of materials and thickness ranges, thereby achieving maximum flexibility and productivity; using ultra-precision aspheric lens processing technology, the laser power drop caused by the lens is reduced to a minimum and reaches The spot quality of limited diffraction enables it to have excellent cutting quality and speed during cutting; it integrates a variety of internal sensors, which can dynamically monitor the entire cutting process, directly evaluate and analyze the reasons for the change of cutting ability, collect the key parameters of the corresponding process, and use Related algorithms drive the improvement and optimization of the process flow, and finally realize the intelligent control of laser cutting through seamless docking and fusion with the cutting system.