Wide Sanding Capability (1000mm Working Width)The machine boasts a 1000mm working width, allowing it to process large sheets of metal with high efficiency. The wide sanding area provides flexibility for handling various part sizes, whether it's for batch production or larger-scale operations.

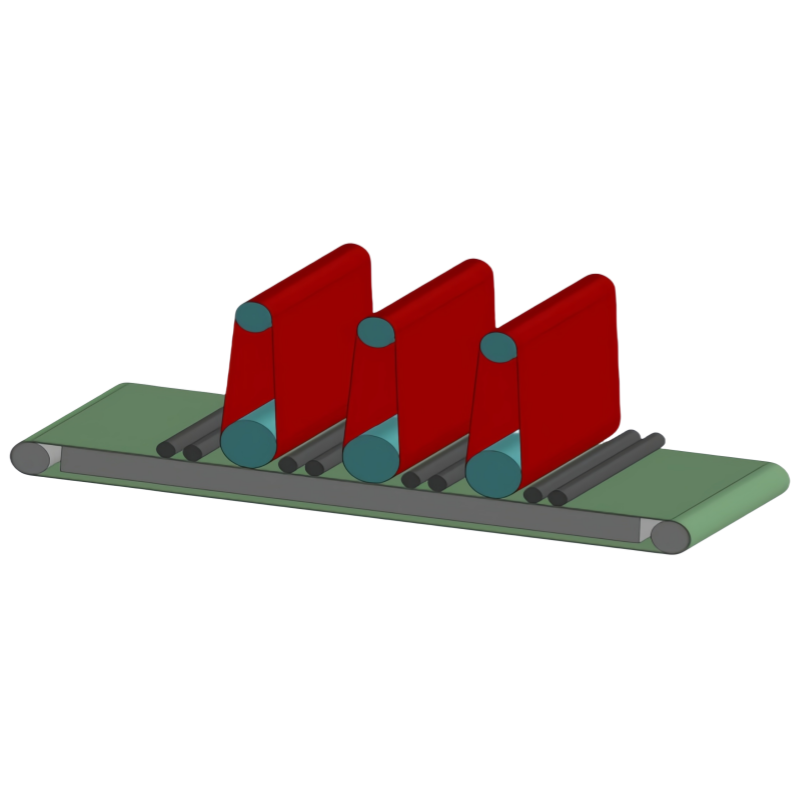

Three Belt ConfigurationFeaturing a 3-belt sanding system, the machine utilizes multiple abrasive belts to perform different finishing tasks in a single pass. Each belt can be tailored to different grits, offering a progressive approach to sanding that smooths rough surfaces while preparing them for additional finishing processes.

First Belt (Coarse Grit): The first abrasive belt typically handles heavy material removal, such as deburring, surface cleaning, and rust removal.

Second Belt (Medium Grit): The second belt is used for refining the surface, removing any remaining imperfections, and ensuring an even surface finish.

Third Belt (Fine Grit): The third belt is designed for final polishing and fine finishing, resulting in a smooth, uniform surface ready for further processing or use.

Wet Sanding ProcessThe machine operates using a wet sanding process, in which a liquid is applied to the sanding belts, reducing friction and heat buildup, preventing dust generation, and ensuring a smoother finish. This process is particularly effective for removing burrs, oxidation, and other imperfections without over-heating or damaging the material. The wet method also helps in extending the lifespan of the sanding belts and provides superior dust control, creating a safer and cleaner working environment.

Conveyor SystemThe machine is equipped with an efficient conveyor system, which continuously moves metal parts through the sanding process. The conveyor ensures consistent pressure and speed, optimizing sanding uniformity across all parts. Adjustable conveyor speeds allow operators to fine-tune the process to match the required surface finish and material type.

Precise Dust ExtractionEquipped with an integrated dust extraction system, this sander ensures that dust and debris generated during the sanding process are effectively captured and filtered out. The wet sanding process minimizes airborne particles, making the machine safer and more environmentally friendly compared to traditional dry sanding methods.

User-Friendly InterfaceThe control panel of the 1000mm 3-Belt Wet Wide Belt Sander is designed for ease of use, featuring intuitive settings for speed control, belt tensioning, and monitoring of sanding parameters. Operators can easily adjust settings to suit various materials and surface finish requirements.

High Power MotorsThe sander is powered by high-performance motors that drive the sanding belts and the conveyor system. With a 15 kW motor for the first belt, a 11 kW motor for the second belt, and a 7.5 kW motor for the third belt, the machine delivers consistent and powerful performance across all sanding stages. This ensures that even the most demanding sanding applications can be handled efficiently.

Versatile ApplicationsThe machine is versatile enough to handle a wide range of metalworking applications, including:

Deburring: Removing sharp edges and burrs from laser-cut, punched, or stamped metal parts.

Surface Finishing: Providing a smooth, uniform finish on various metal surfaces, ideal for polishing and smoothing.

Oxide and Rust Removal: The wet sanding process helps to remove oxide layers and surface rust from metal parts, improving the appearance and preventing corrosion.

Edge Rounding: Softening the edges of metal parts to ensure safety and improve the overall quality of the product.

Adjustable Belt Tension and SpeedThe sander’s belts are tensioned and adjusted to ensure optimal contact with the workpiece, providing consistent pressure during the sanding process. The belt speed can also be adjusted, allowing for fine control over the sanding results. This feature is critical for applications requiring precise and uniform finishes across different material types and thicknesses.

Sturdy and Durable ConstructionThe machine’s frame is built from high-quality materials designed to withstand the rigors of continuous industrial use. The construction is robust, ensuring stability and minimal vibration during operation, contributing to the accuracy and longevity of the machine.