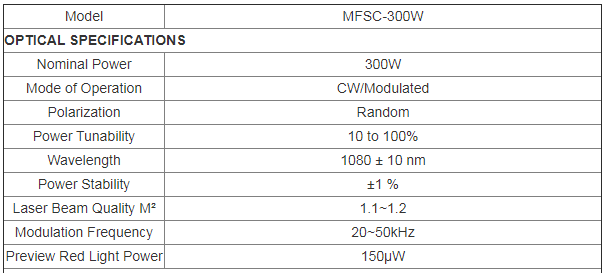

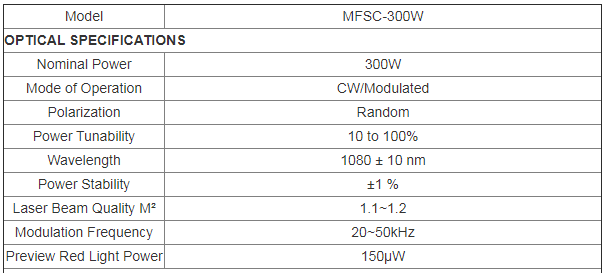

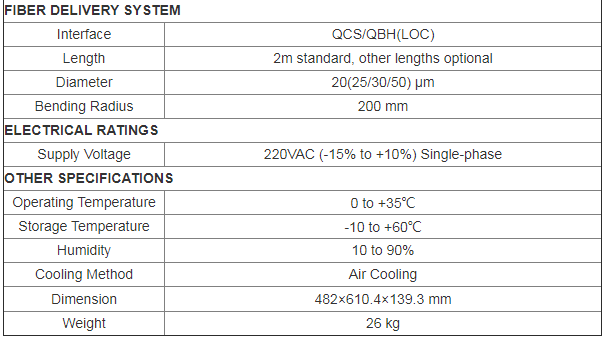

MAX MFSC-300W single-mode continuous fiber laser (3D printing)

Product description:

It is used in welding, cutting, and drilling in 3C, hardware, medical, new energy and other industries. It can also meet the stringent demands of titanium alloy and metal 3D printing in medical, aerospace, automotive and other fields.

Product Description:

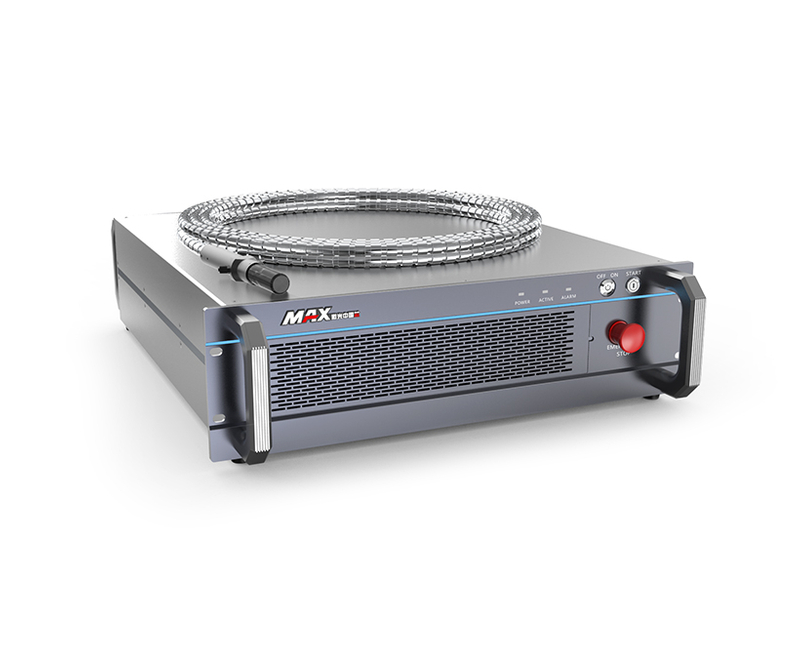

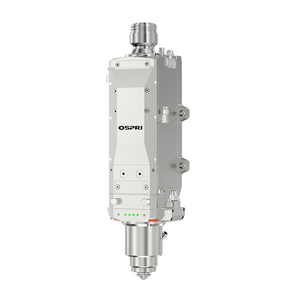

MFSC 300W single-mode continuous laser (3D printing), based on modular design, has excellent beam quality and extremely high stability. Using intelligent air cooling, compact structure. The laser power is continuously adjustable, and the optical fiber is equipped with a QBH head output. It can be used with laser processing heads, galvanometers, etc. for system integration with robots, machine tools, etc., to provide mature and reliable welding and cutting applications for 3C, hardware, medical, new energy and other industries solution. At the same time, a metal 3D printing version is available, with higher beam quality and more stable laser power, which can meet the strict metal 3D printing needs in the fields of medicine, aerospace, and automobiles.

Modular design

Using photoelectric separation and modular design, the structure is more compact

High beam quality

With higher beam quality and more stable laser power, the laser power is continuously adjustable

Smart air cooling

Efficient heat dissipation, more effective protection of the laser

Convenient integration

Can be used with laser processing heads, galvanometers, etc. for system integration with robots, machine tools, etc.

Wide range of applications

Provides mature and reliable welding, cutting, drilling and other application solutions for 3C, hardware, medical, new energy and other industries, and can meet the strict requirements of titanium alloy and metal 3D printing in the fields of medicine, aerospace, automotive, etc.

Industry application:

Kitchen and bathroom

Sink/faucet/kitchenware stainless steel cutting and welding, kitchenware panel characters/graphic markings

Industry Application

jewelry

Ring/necklace/cut gold, marking characters/pattern

Industry Application

Advertising

Cutting and welding of metal billboards/advertisement racks. Ad text marking

Industry Application

aerospace

3D printed metal parts inside the aircraft, aircraft engine/