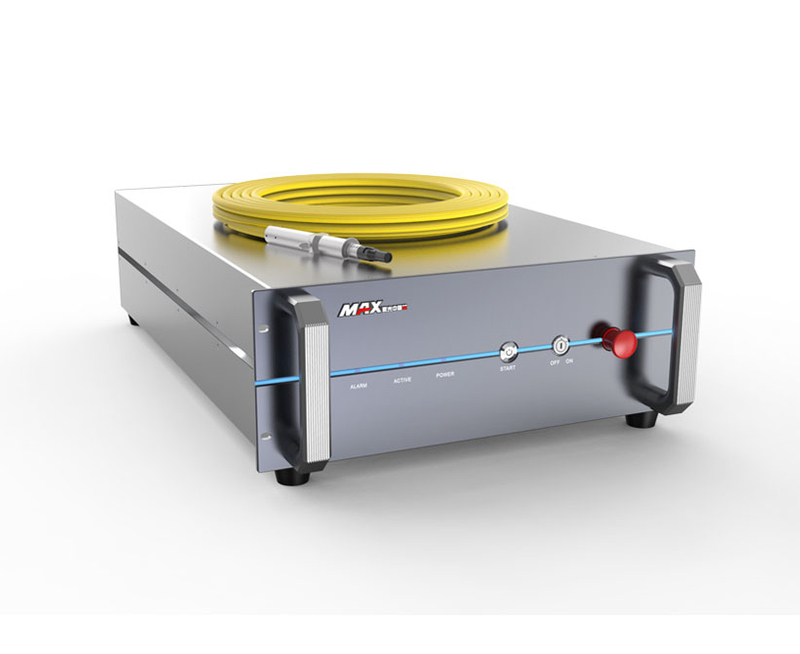

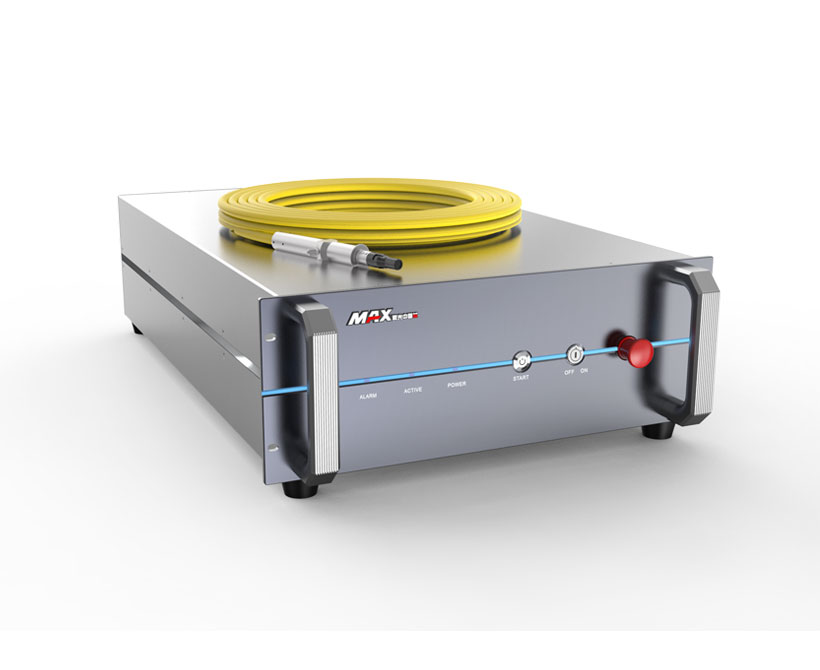

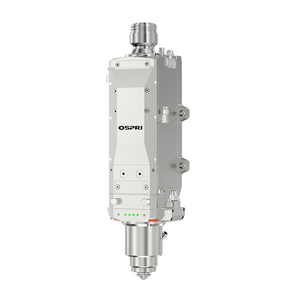

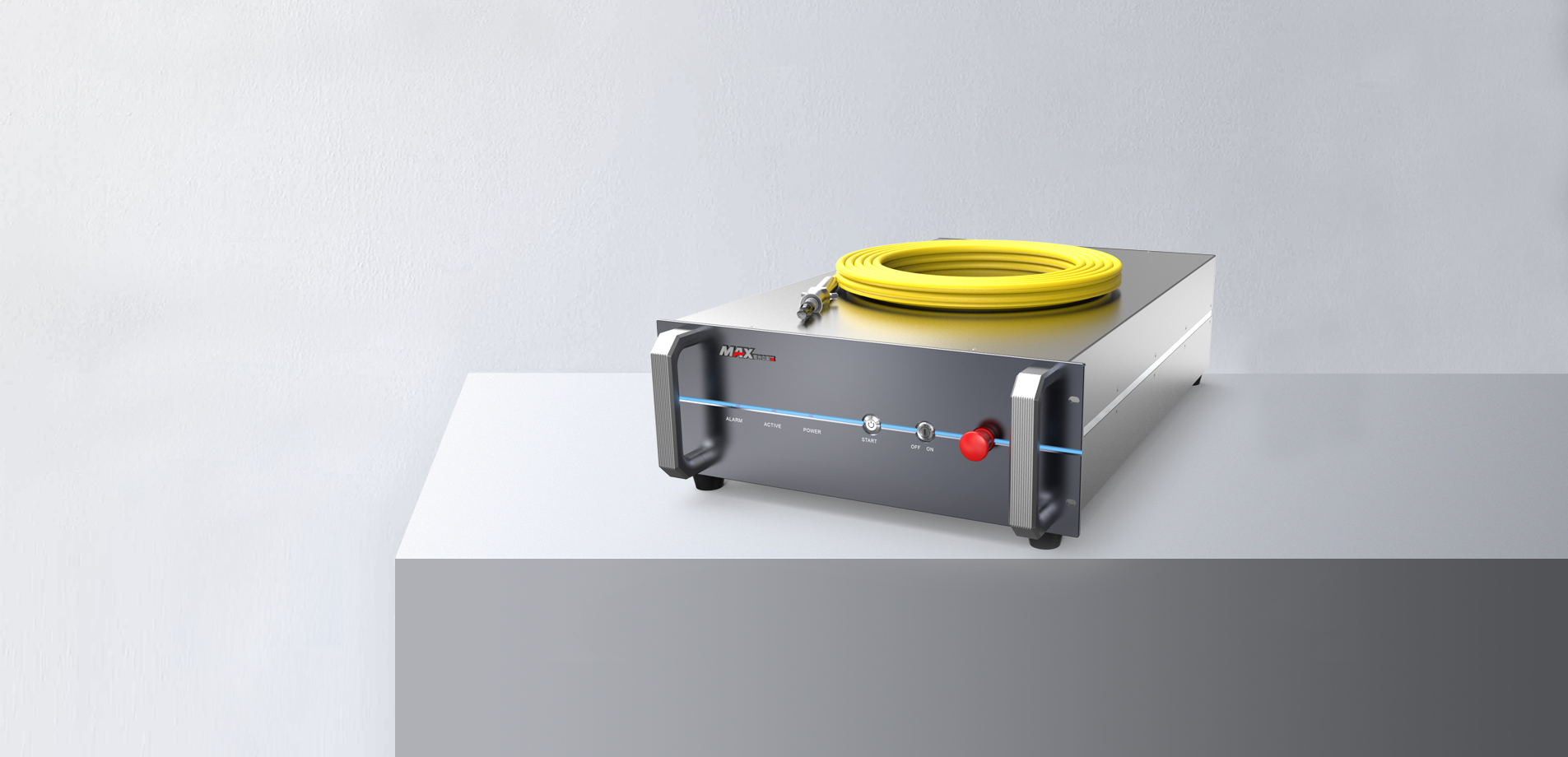

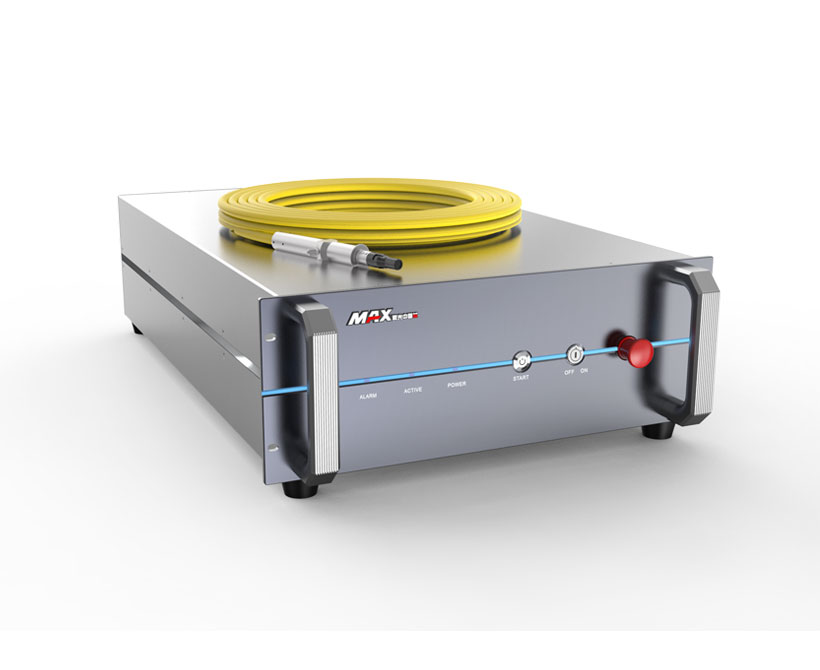

MAX MFSC-700W-1500W single-mode continuous fiber laser

product description:

It can be used with laser processing heads, galvanometers, etc. for system integration with robots, machine tools, etc., for laser fine cutting and precision welding.

Product Description:

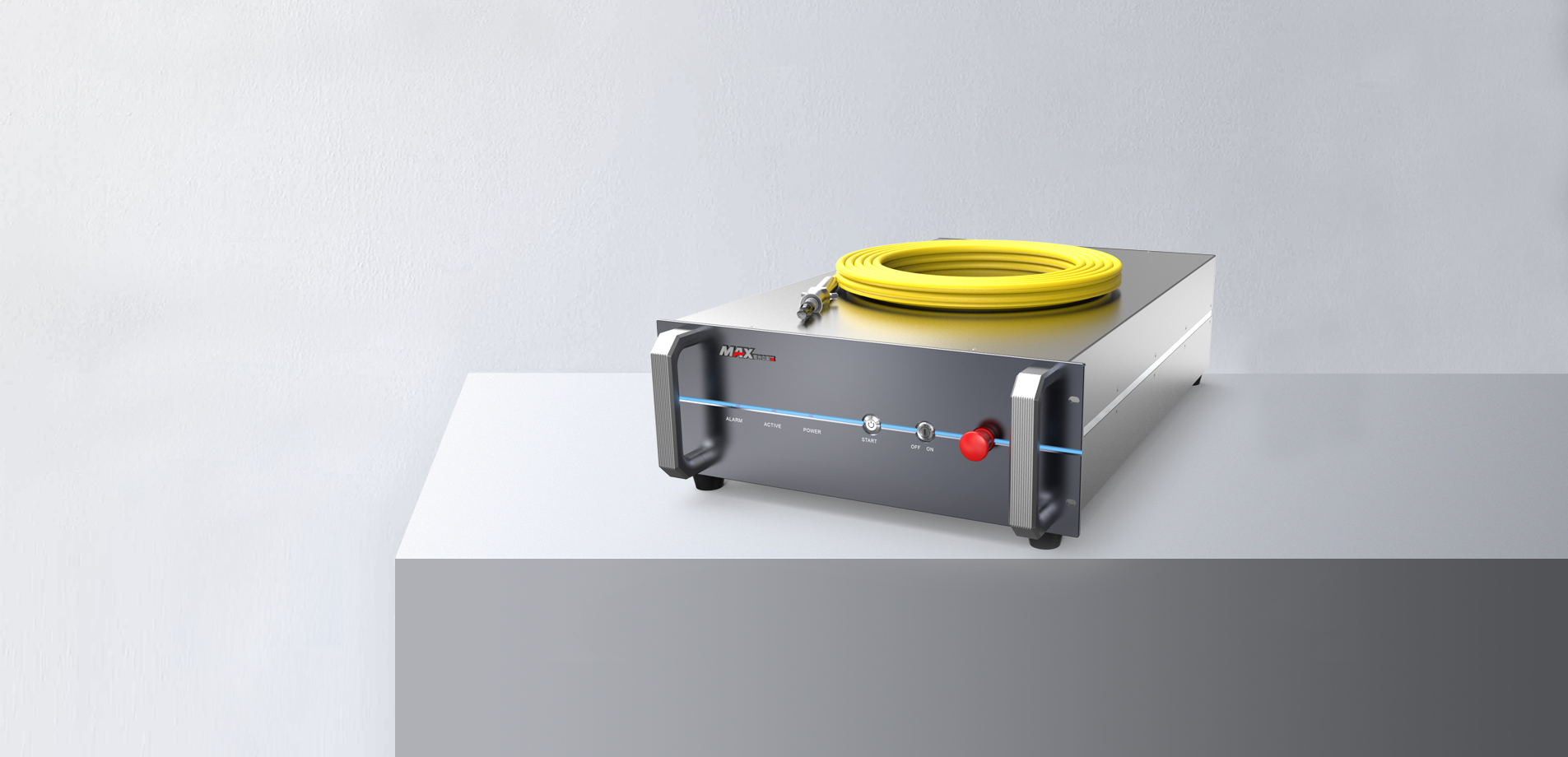

MFSC 700W-1500W single-mode continuous fiber laser adopts modular design, highly integrated system, maintenance-free, and high reliability. The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cutting, precision welding and other applications. Using optical fiber with QBH head output, it can be used with laser processing heads, galvanometers, etc. to integrate with robots, machine tools, etc., and is widely used in 3C, hardware, medical, automotive, aviation and other fields.

Modular design, stable performance

The internal structure adopts the photoelectric module separation design, and the operating performance is more stable

Easy maintenance, reducing downtime

Optical modules, electrical modules, control units, and drive units can be directly replaced, upgraded, and maintained at the client

Can be customized to meet a variety of needs

Users can choose fibers with different core diameters according to different processing needs to meet differentiated processing needs

Even spot energy distribution, stable processing

Reduce welding spatter, thick plate cutting ability is more stable

Multi-scene, wide application

It can be used with laser processing heads, galvanometers, etc. for system integration with robots, machine tools, etc., for laser fine cutting, precision welding, and application in 3C, hardware, medical, automotive, aviation and other fields

3mm Stainless Steel Cutting

6-12mm Carbon Steel Cutting

Telecommunications Industry

Communication jumper / cable / optical cable marking

Sheet Metal Processing

Cutting and welding of steel plates and tubes

Construction Material

Laser cutting of construction iron frames, cutting of doors and windows, cleaning of rust on iron frames, welding of iron frames

Shipbuilding

Laser cleaning of ships, laser cutting / welding of hulls

Home Appliance Manufacturing

Sink / faucet / kitchenware stainless steel cutting and welding,Kitchenware panel character / graphic marking

Petrochemical Industry

(Welding and cutting of petroleum pipelines), laser cleaning of pipelines

Advertising Industry

Cutting and welding of metal billboards / advertising stands. Advertising character marking

3C Consumer Electronics

Character marking for accessories such as mobile phones / tablets / computers and charging heads, internal antenna / middle board / camera welding. Volume hole perforation

Scientific Research

The laser illuminates the object, and the internal structure emits changes. Laser irradiation promotes physical / chemical reactions of materials, laser fusion

AEROSPACE

3D printing metal parts inside the aircraft, laser cleaning and refurbishment of aircraft engines / airframes

Photovoltaic

Laser scribing of solar panels

Packing

Flying marking of cans / plastic food packaging. Flying marking of plastic bottle

Clocks Watches

Dial / back cover character / graphic mar

| Models | MFSC-1000W | MFSC-1500W |

| OPTICAL SPECIFICATIONS |

| Nominal Power | 1000W | 1500W |

| Mode of Operation | CW/Modulated |

| Polarization | Random |

| Power Tunability | 10 to 100% |

| Wavelength | 1080 ± 10 nm |

| Power Stability | ±1 % |

| Laser Beam Quality, BPP | ≤1.5 mm x mrad (50μm QBH) |

| Modulation Frequency | ≤20 kHz |

| Preview Red Light Power | 150 μW |

| FIBER DELIVERY SYSTEM |

| Interface | QBH (LOC) |

| Length | 15m standard, other lengths optional |

| Diameter | 50 μm |

| Bending Radius | 200 mm |

| ELECTRICAL RATINGS |

| Supply Voltage | 220VAC (-15% to +10%) Single-phase |

| OTHER SPECIFICATIONS |

| Operating Temperature | +10 to +40℃ |

| Storage Temperature | -10 to +60℃ |

| Humidity | 10 to 85% |

| Cooling Method | Water Cooling |

| Cooling Medium | Distilled water/ Glycol Antifreeze |

| Dimension | 482.6×800×193mm (W×D×H) |

| Weight | 53(±3) kg | 57(±3) kg

|