product description:

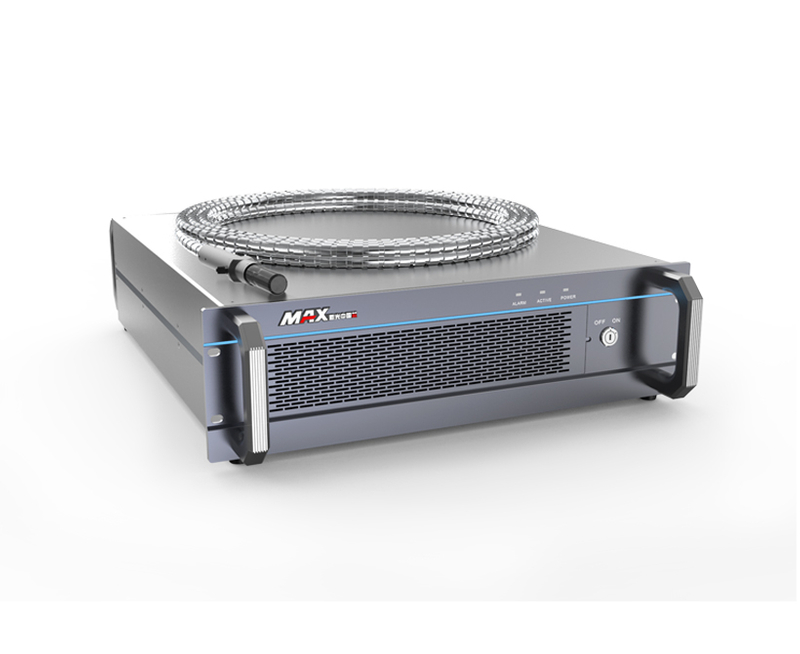

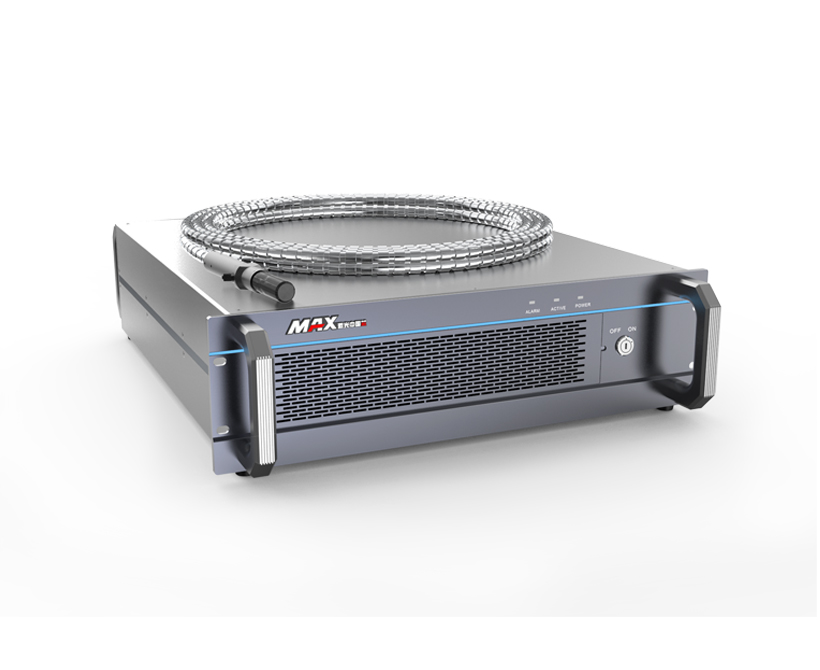

MAX MFSQ-150W/1500W QCW quasi-continuous fiber laser

It can meet 3C fine welding and metal/non-metal fine cutting at the same time.

Product Description:

The product has multiple compatibility and control modes, can switch between pulse and continuous modes, and can handle the processing tasks of two different lasers at the same time. The pulse width waveform is flexible and adjustable, the heat dissipation is fast, the electro-optical conversion rate is more than 30%, and it is a long pulse width. , Another choice for high-energy applications.

Mode switchable

Can switch between pulse and continuous mode, and simultaneously handle the processing tasks of two different lasers in the past

Customizable

Users can choose fibers with different core diameters and customize arbitrary waveforms to meet the needs of differentiated processing

Diverse compatibility

High pulse power, stable energy, and high peak power

Convenient integration

Can be directly integrated into user equipment

Wide range of applications

It can meet 3C fine welding and metal/non-metal fine cutting at the same time

Sample Show:

Stainless Steel Plate Drilling

Battery Electrode Welding

Electronic Components Precision Welding

Industry application:

jewelry

Ring/necklace/cut gold, marking characters/pattern

Advertising

Cutting and welding of metal billboards/advertisement racks. Ad text marking

3C Consumer Electronics

Character mark of accessories, such as mobile phone/tablet/computer and charging head, internal antenna/middle board/camera welding. Volumetric hole perforation

Scientific research

When the laser irradiates the object, the internal structure changes. Laser irradiation promotes physical/chemical reactions of materials and laser fusion

Power Battery

Power cell cutting/welding, battery shell/pole/explosive valve welding

aerospace

3D printed metal parts inside the aircraft, laser cleaning and refurbishment of aircraft engines/fuselages

Clock

Dial/back cover characters/graphic marks, hands/gears/cut

| Model | MFSQ-150/1500W |

| OPTICAL SPECIFICATIONS |

| CW Mode Max Power | 250W |

| Pulsed Mode Max Power | 1500W |

| Mode of Operation | CW/Modulated |

| Polarization | Random |

| Power Tunability | 10 to 100% |

| Wavelength | 1080 ± 10 nm |

| Power Stability | 2% |

| Laser Beam Quality M² | 1.3(20um) |

| Pulse Energy | 15 J |

| Pulse Duration | 0.1~50 ms |

| Repetition Rate | 1~5000 Hz |

| Preview Red Light Power | 100 μW |

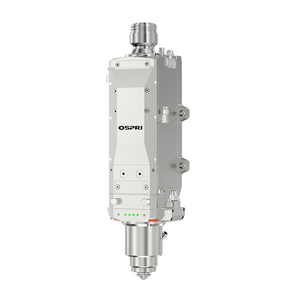

| FIBER DELIVERY SYSTEM |

| Interface | QBH (LOC) |

| Length | 10 m standard, other lengths optional |

| Diameter | 20/50 μm |

| Bending Radius | 200 mm |

| ELECTRICAL RATINGS |

| Supply Voltage | 220VAC |

| Rated Power | 3 KW |

| OTHER SPECIFICATIONS |

| Operating Temperature | +10 to +40℃ |

| Storage Temperature | -10 to +60℃ |

| Humidity | 10 to 85% |

| Cooling Method | Air Cooling |

| Dimension | 586×420×142 mm |

| Weight | 34 kg |