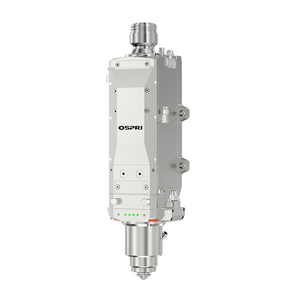

product description:

RayTools BT240S 3.3KW plane cutting head

Upgraded dust-proof design

The risk of contamination of the laser head is almost zero

The BT240S series is based on the design of BT240 by Swiss RAYTOOLS AG, which was launched in 2017 for optical fiber cutting heads suitable for medium and high power industrial applications. Compared with the BT240 series, the upgraded version of the BT240S series has been fully optimized in terms of dust-proof design and customer experience. The risk of contamination of the collimator lens is extremely high when the optical fiber is plugged and unplugged. The BT240S series adds an upper protective lens to the collimating component, which minimizes the risk of contamination of the collimator lens. At the same time, the structure of the protective mirror is also fully upgraded, and a dust-proof cover is added to the protective mirror. The double-layer protection design greatly improves the user's experience in replacing the protective lens, and the risk of lens contamination is almost zero.

product features:

Highly dustproof:

The dustproof grade is IP65, and the light path is completely enclosed, so the possibility of lens contamination is almost zero.

Motion picture zero focus:

The scale can be adjusted flexibly to unify the zero focus position and no longer worry about adjusting the process parameters.

Efficient water cooling:

The focusing lens, collimating lens and nozzle have built-in cooling function, which can solve the problem of cutting heating.

Optimized structural design:

Integrated body design, improved QBH optical fiber interface no longer stuck due to water leakage, rust and other reasons.

technical parameter

Plane cutting head

Power level: 3300W

Focus clear aperture: 28mm

Focal length of collimator lens: 100mm

Focusing lens focal length: 125mm, 155mm, 200mm

Nozzle hole specifications: single layer, double layer, non-standard

Optical fiber interface: QBH, QD, QCS

Nozzle aperture: 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm, 4.5mm, 5.0mm

Protect the lens:

-Collimation protection lens: φ24.9mm*1.5mm

-Focus protection lens: φ27.9mm*4.1mm

Auxiliary gas pressure: ≤25bar

Weight: ~ 3.5kg