1300mm Industrial Belt Sander for Metal: Best Belt Sander for Metal Work Conveyor System

The 1300mm Industrial Belt Sander for Metal is a high-performance machine designed for various metalworking applications such as deburring, finishing, polishing, sanding, and calibrating. This machine is ideal for professionals in industries such as manufacturing, automotive, aerospace, and metal fabrication, offering unparalleled efficiency, precision, and versatility in handling large metal workpieces. With advanced features and capabilities, the industrial belt sander is built to streamline operations, improve quality, and increase productivity.

Technical Specifications

| Parameter | Unit | RR1000 | RRR1000 | RR1300 | RRP1300 |

| Max Working Width | mm | 1000 | 1000 | 1300 | 1300 |

| Max Working Height | mm | 60 | 60 | 60 | 60 |

| Min Workpiece Length | mm | 250 | 250 | 350 | 350 |

| First Sanding Belt Power | kW | 15 | 15 | 30 | 30 |

| Second Sanding Belt Power | kW | 11 | 11 | 22 | 22 |

| Third Sanding Belt Power | kW | / | 11 | / | / |

| Polishing Wheel Power | kW | / | / | / | 15 |

| Rotating Motor Power | kW | / | / | / | / |

| Feeding Motor Power | kW | 3 | 3 | 4 | 4 |

| Vertical Adjustment Power | kW | 0.37 | 0.37 | 0.55 | 0.55 |

| Oscillating Motor Power | kW | / | / | / | 2.2 |

| Vacuum Motor Power | kW | / | / | / | / |

| Machine Dimensions | m | 2.3 x 2.1 x 2 | 2.6 x 2.1 x 2 | 2.8 x 2.4 x 2.1 | 3.1 x 2.4 x 2.1 |

| Machine Weight | kg | 2500 | 2900 | 3500 | 3800 |

| Sanding Belt Size | mm | 2000 x 1050 | 2000 x 1050 | 2200 x 1350 | 2200 x 1350 |

Introduction to the 1300mm Industrial Belt Sander for Metal

A belt sander is an indispensable tool in the metalworking industry. The 1300mm Industrial Belt Sander for Metal features a wide sanding belt, typically 1300mm in width, allowing it to handle larger workpieces and deliver consistent, high-quality finishes on metal surfaces. This machine can be equipped with multiple sanding belts, varying grit sizes, and polishing wheels, making it suitable for a wide range of applications from heavy-duty grinding to fine finishing.

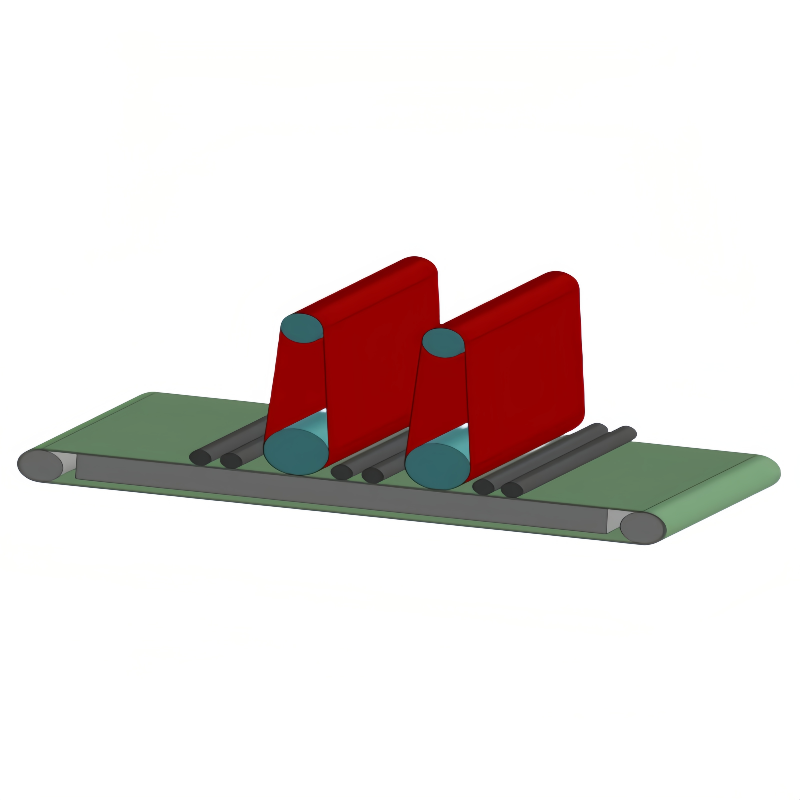

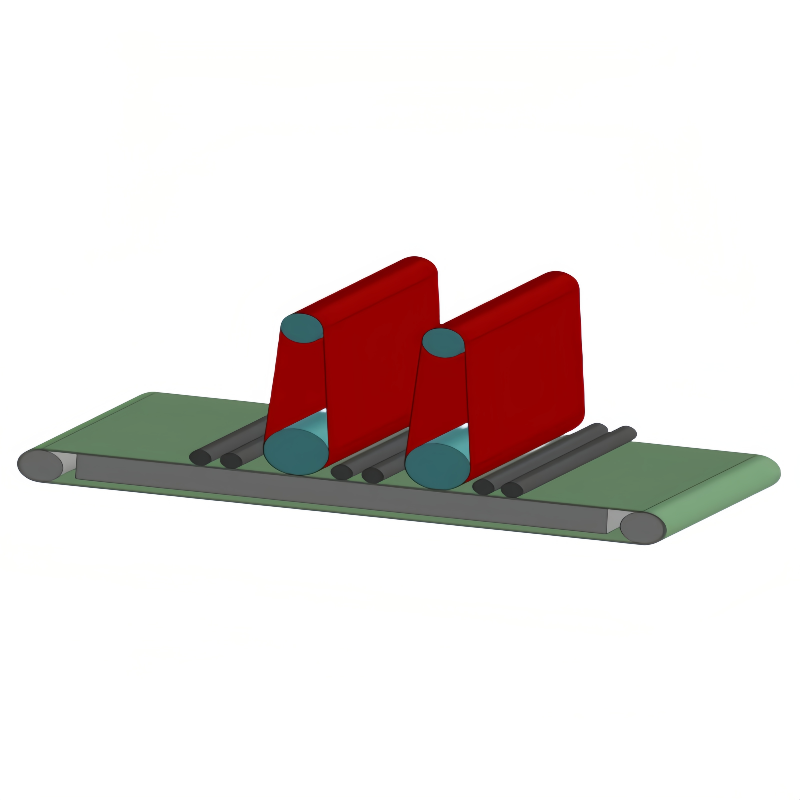

This type of industrial belt sander is typically equipped with a conveyor system to feed materials into the machine, enhancing automation, speed, and efficiency. A key advantage of the 1300mm Industrial Belt Sander is its adjustable sanding settings, enabling operators to tailor the machine for different metal surfaces, from aluminum to stainless steel.

Key Features and Specifications

1. Workpiece Handling and Capacity

The 1300mm wide belt allows the machine to accommodate large metal sheets, plates, and sections for sanding and finishing. The typical dimensions for such machines include a maximum working width of 1300mm, which ensures that even large metal parts can be processed without the need for multiple passes. The working height of up to 60mm is designed to accommodate both thin and thick workpieces, providing flexibility for different material thicknesses.

Maximum working width: 1300mm

Maximum workpiece height: 60mm

Minimum workpiece length: 250mm to 350mm, depending on the model

Sanding belt size: 2000mm x 1300mm, designed for optimal material coverage

2. Powerful Motorized System

Equipped with powerful motors, the 1300mm Industrial Belt Sander for Metal operates with substantial force to perform heavy-duty sanding, grinding, and polishing tasks. The main motor, typically rated between 15kW to 30kW depending on the model, drives the sanding belts to ensure consistent and fast material removal, making it an ideal choice for large-scale metalworking shops.

First sanding belt motor power: 15kW – 30kW

Second sanding belt motor power: 11kW – 22kW

Polishing wheel motor power: Optional, up to 15kW (depending on the model)

These motorized systems deliver reliable performance even in demanding environments, enabling high throughput while maintaining surface quality.

3. Conveyor System with Adjustable Feed Rate

The conveyor system integrated into the industrial belt sander enhances ease of use and material handling. It automatically feeds the metal workpieces through the machine, ensuring a continuous, high-speed operation. The conveyor speed is adjustable, offering the flexibility to control the material's feed rate based on the type of material and the desired sanding or finishing result. This feature is essential for achieving uniform results across a variety of metal parts.

4. Multi-Belt Configuration for Versatility

The industrial belt sander can be configured with multiple sanding belts, each serving different functions. The three-belt configuration (including coarse, medium, and fine grits) ensures that the machine can handle a variety of tasks from deburring and edge rounding to surface finishing. The addition of polishing wheels or brushes further enhances the machine’s versatility, providing options for high-quality finishing.

Multiple sanding belts: Typically 3 belts for coarse, medium, and fine sanding

Polishing wheel: Available on higher-end models for advanced finishing

5. Precision Adjustment and Control

For professional results, the 1300mm Industrial Belt Sander for Metal is designed with precision adjustment systems. These systems allow operators to control the gap between the sanding belt and the workpiece, ensuring a smooth and consistent finish. The height, speed, and angle of the sanding belt can be adjusted to optimize sanding quality and material removal rates. The inclusion of digital controls or an HMI (Human-Machine Interface) ensures user-friendly operation, while servo-driven systems provide fine adjustments for precise finishing.

Adjustable sanding pressure and speed

Digital control panel for easy operation

Servo motors for fine adjustments

Applications of the 1300mm Industrial Belt Sander for Metal

The 1300mm Industrial Belt Sander for Metal is used in a variety of applications in the metalworking industry:

1. Metal Deburring and Edge Rounding

One of the most common uses of this sander is for deburring, where it removes sharp edges and burrs from metal parts. This is especially important after processes such as laser cutting, plasma cutting, and shearing, where burrs and jagged edges are created. The sander’s abrasive belts can smooth out these imperfections, making parts safer to handle and improving their appearance.

Additionally, the sander’s edge rounding function allows it to create smooth, rounded edges on metal parts, which is essential for improving both aesthetics and safety.

2. Surface Finishing and Polishing

The 1300mm industrial belt sander is also used for surface finishing. It can create a consistent surface texture on various metals such as steel, aluminum, and stainless steel. With fine-grit sanding belts or polishing wheels, the sander can achieve a polished, smooth finish ideal for decorative metal applications or components that require high-quality surface textures.

3. Calibrating

The sander can also be used for calibrating metal sheets or plates to precise thicknesses. The machine's adjustable sanding pressure ensures that the material thickness is uniformly reduced, achieving the required dimensions with high accuracy.

4. Paint and Coating Removal

In some cases, the 1300mm industrial belt sander is used for removing paint, coatings, or rust from metal surfaces. The abrasive action of the sanding belts efficiently removes old coatings, preparing the surface for refinishing, re-coating, or welding.

5. Automotive and Aerospace Parts Manufacturing

In the automotive and aerospace industries, the ability to achieve consistent finishes on metal parts is crucial. Whether it's for frame components, engine parts, or structural elements, the 1300mm Industrial Belt Sander for Metal offers the precision and power needed for such applications.